A method for estimating pipe removal depth in concrete pouring based on artificial intelligence video analysis

A technology of video analysis and artificial intelligence, applied in the field of construction engineering, can solve the problems of loose management, less action, and uneven quality of side station supervisors, so as to improve human efficiency, avoid potential risks, and facilitate retrieval and backtracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

[0031] A method for estimating pipe removal depth in concrete pouring based on artificial intelligence video analysis, the method comprising:

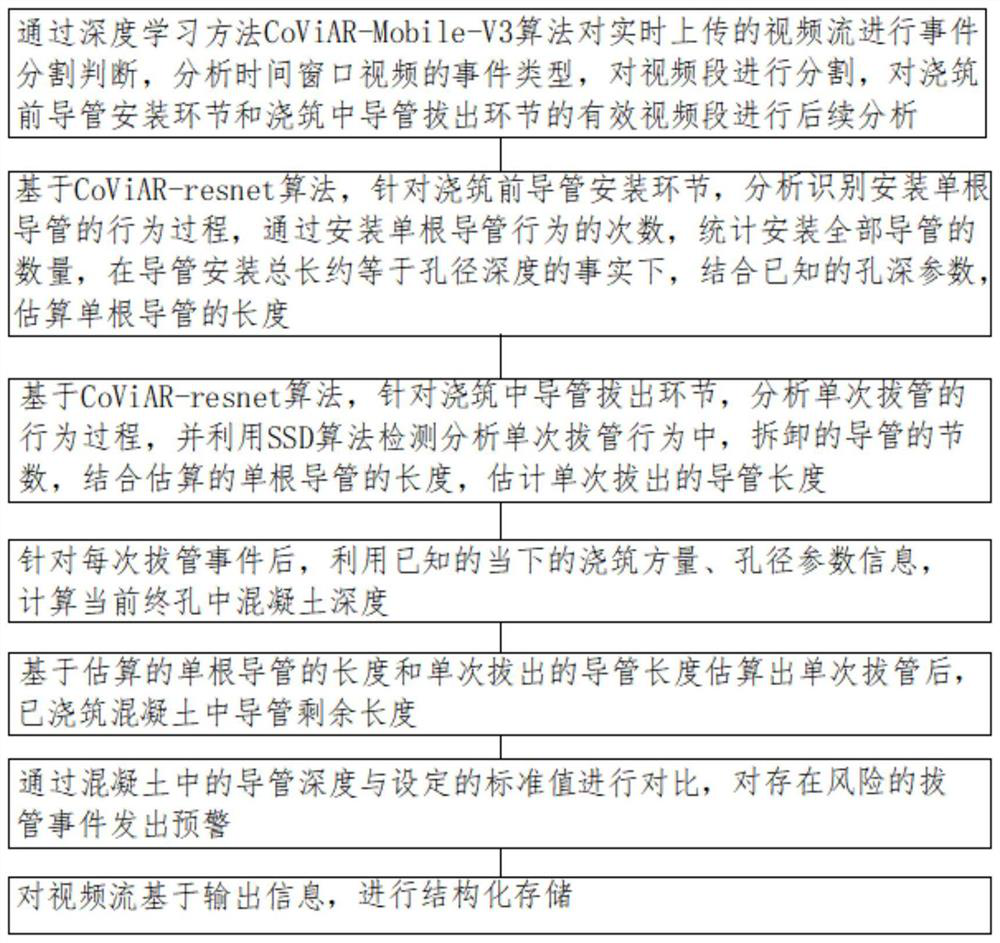

[0032] a1. Use the deep learning method CoViAR-Mobile-V3 algorithm to segment and judge the real-time uploaded video stream, analyze the event type of the time window video, segment the video segment, and analyze the tube installation before pouring and the tube pull out during pouring Valid video segments for subsequent analysis;

[0033] a2. Based on the CoViAR-resnet algorithm, aiming at the installation of conduits before pouring, analyze and identify the behavior process of installing a single conduit, and count the number of all conduits installed by counting the number of installed conduits. The total length of conduit installation is approximately equal to the depth of the hole diameter In fact, combined with k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com