Combinable electrostatic kinetic energy collector and preparation method thereof

A collector and electrostatic technology, applied in the field of electrostatic kinetic energy collectors and their preparation, can solve the problems of structural adjustment in applications that cannot be applied, cannot make full use of kinetic energy collection space, and reduce kinetic energy collection efficiency, etc., so as to improve kinetic energy collection efficiency, The effect of expanding the structural diversity and making full use of the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

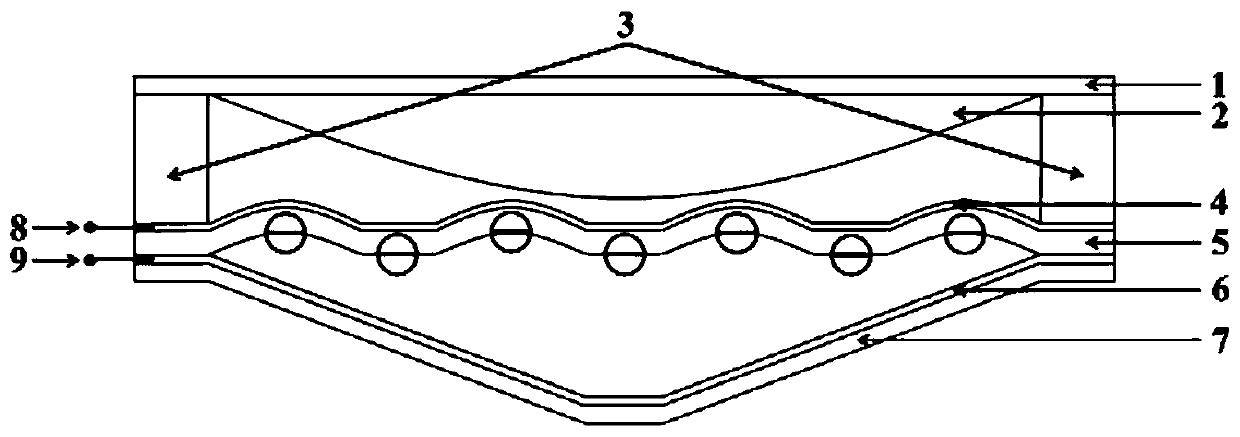

[0060] A kinetic energy harvester with a V-shaped groove and a polymer film whose upper surface is covered with an upper electrode. The preparation process is as follows:

[0061] (1) Select a suitable polymer material (such as PTFE, FEP, PET, PE, PP, etc.), and make a highly elastic polymer film 5 by casting, embossing, and casting. The polymer film 5 is a wavy structure;

[0062] (2) Cover a layer of conductive electrodes on one surface of the polymer film 5 by vacuum evaporation, which is the upper electrode 4, and the upper electrode 4 and the polymer film 5 jointly form an electret film;

[0063] (3) inject real negative charges to the free surface of the polymer film 5 not covering the electrode by means of corona polarization, contact charging, ion implantation or electron beam implantation;

[0064] (4) Select a thermoplastic material (such as PET, PE, PVC, PP, TPV, PC, TPU, etc.) or metal material (Al, Au, stainless steel, etc.), and make the groove 7 through the pro...

Embodiment 2

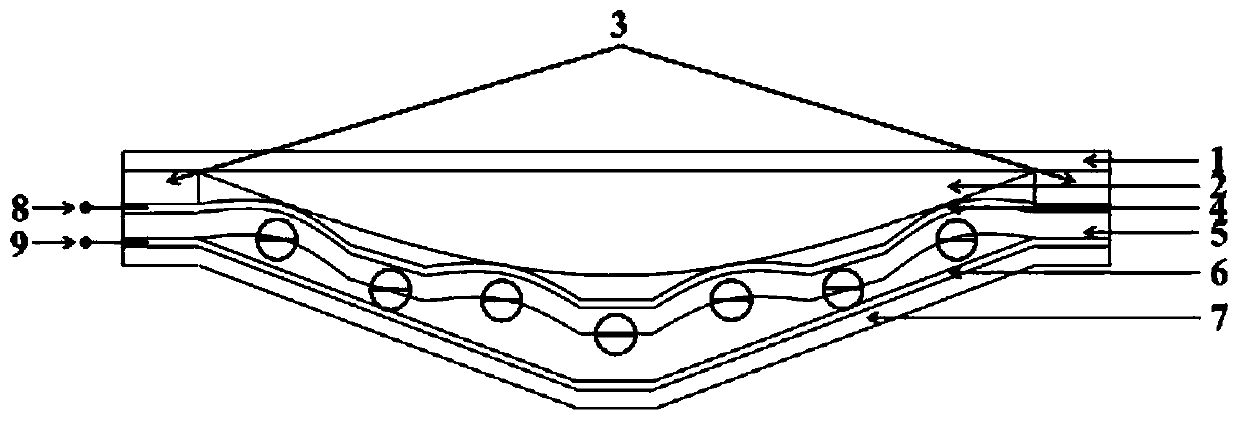

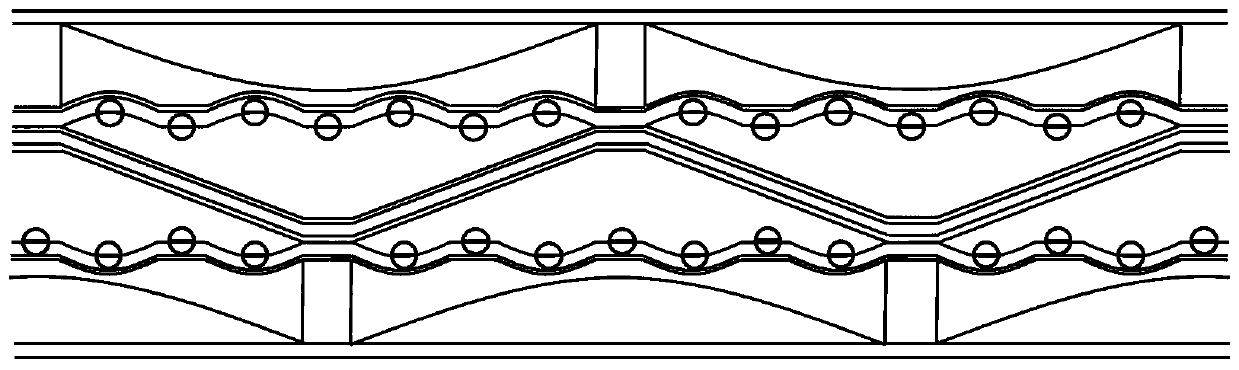

[0083] The kinetic energy harvester with arc-shaped grooves and the upper surface of the polymer film covered with the upper electrode is similar to the preparation process of the single-structure kinetic energy harvester in Example 1, except that the groove 7 is an arc-shaped structure in step (4). Specific as Figure 5 shown. Similarly, when the kinetic energy harvester is subjected to external pressure (or vibration excitation), such as Figure 6 shown in the compression deformation, and by stacking up and down and tiling left and right, multiple kinetic energy harvesting devices can be combined together to obtain the following Figure 7 In the combined kinetic energy harvester shown, among the two single-structure kinetic energy harvesters stacked up and down, the arc-shaped groove of the upper kinetic energy harvester can also play the role of replacing the half-moon-shaped support member, so this combination is further improved. The volume of the whole combined kinetic...

Embodiment 3

[0095] The kinetic energy harvester with V-shaped grooves and the lower surface of the polymer film covering the lower electrode, the preparation process is as follows:

[0096] (1) Select a suitable polymer material (such as PTFE, FEP, PET, PE, PP, etc.) to make a polymer film 5;

[0097] (2) Cover a layer of conductive electrodes on one surface of the polymer film 5 by vacuum evaporation, which is the lower electrode 6, and the lower electrode 6 and the polymer film 5 jointly form an electret film;

[0098] (3) inject real negative charges to the free surface of the polymer film 5 not covering the electrodes by methods such as corona polarization, contact charging, ion implantation or electron beam implantation;

[0099] (4) Select a thermoplastic material (such as PET, PE, PVC, PP, TPV, PC, TPU, etc.) to make the groove 7 through the processing procedure, and the groove 7 is a V-shaped structure;

[0100] (5) One side of the polymer film 5 covering the electrode with a rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com