Food processing rectangular feeding barrel

A technology for food processing and feeding barrels, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of reducing coffee bean production efficiency, labor consumption, etc., to slow down the falling speed, facilitate production, and improve The effect of efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

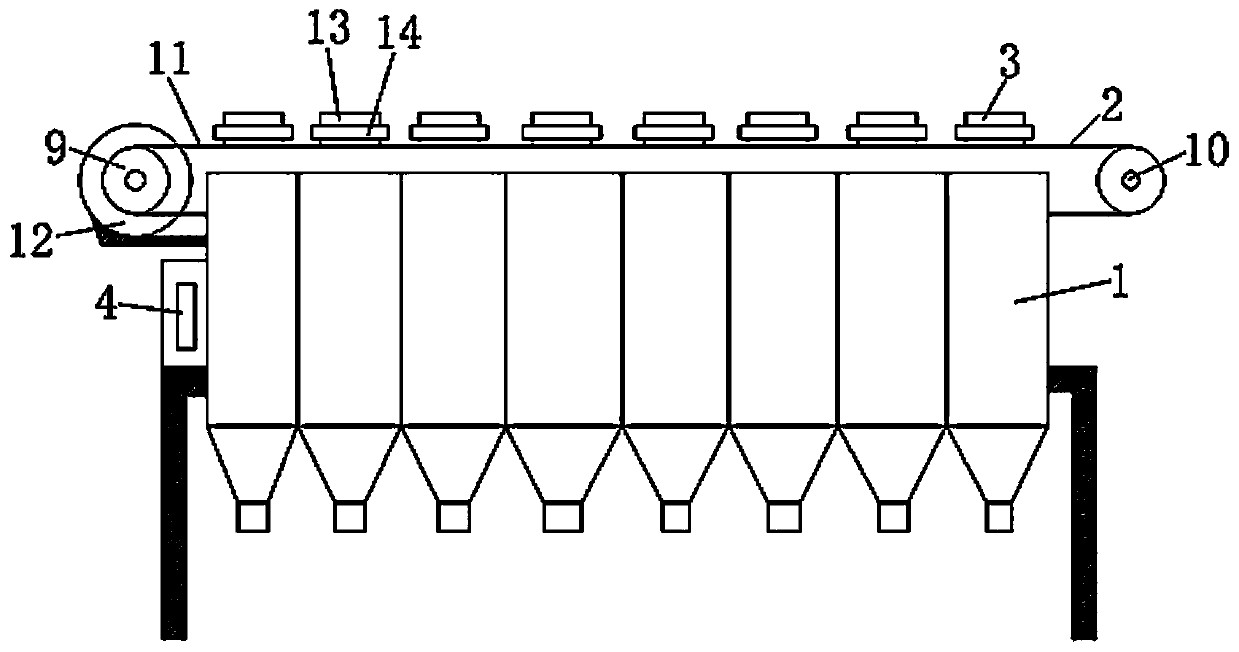

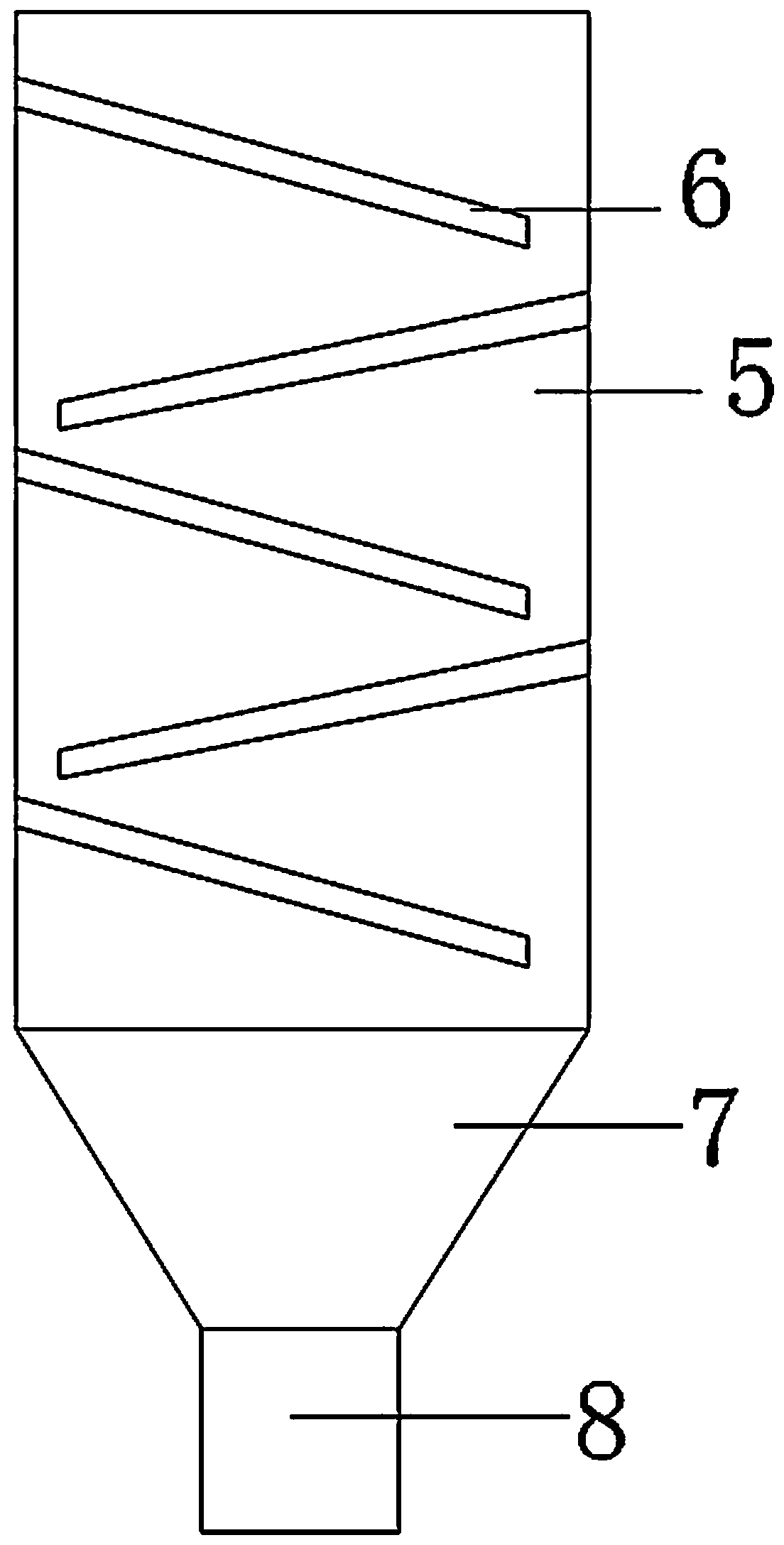

[0017] Figure 1-2 The specific implementation of the present invention is shown: a food processing rectangular feed barrel, including a feeding trough 1, a feeding track 2, a material shifting device 3, and a wireless signal controller 4, eight feeding troughs 1 are arranged side by side, and a feeding track 2 It is arranged on the upper side of the feeding trough 1, and eight material shifting devices 3 are arranged on the side of the feeding crawler 2. The shifting device 3 corresponds to the position of the feeding trough 1, and the wireless signal controller 4 is set in the feeding trough On 1, it is connected with the signal of the feeding device 3 and the feeding track 2. This device can automatically send coffee beans into the designated trough through automation equipment, which greatly improves the efficiency and accuracy of coffee production. This device is automated The equipment can automatically send coffee beans into the designated trough, which facilitates produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com