Dismountable and mountable rapid breach repairing structure

A technology for repairing structures and structures, applied in water conservancy projects, embankments, marine engineering, etc., can solve problems such as difficult to support the skeleton, burst erosion, slow burst sealing, etc., to increase the anti-scour capacity, reduce the burst flow rate, and reduce water The effect of flow energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

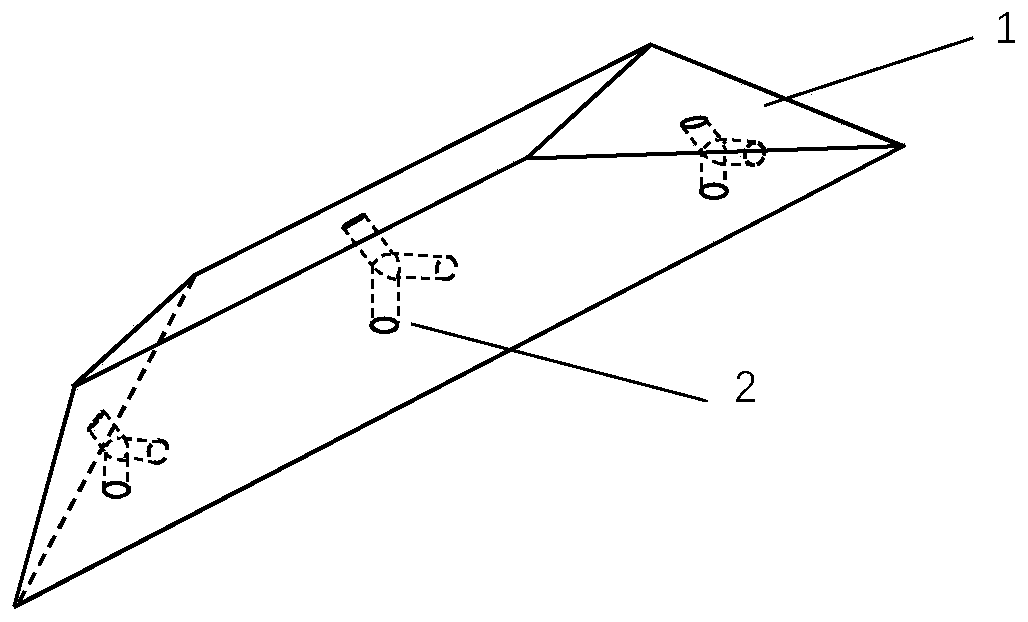

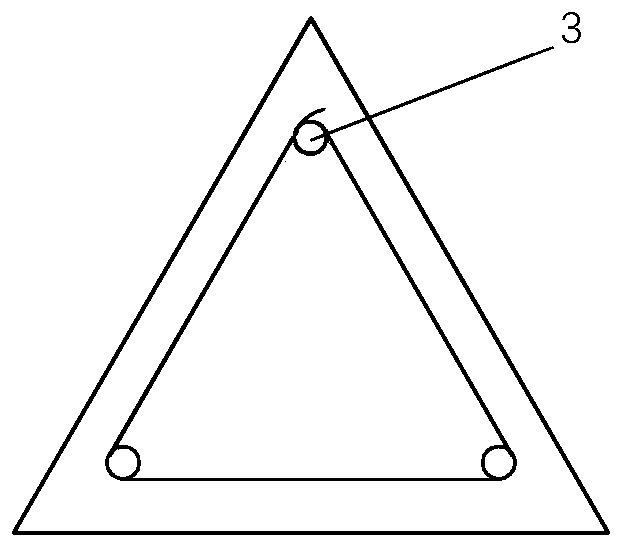

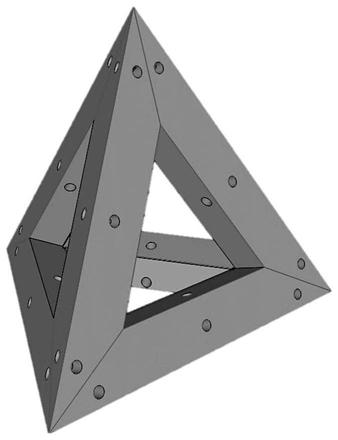

[0019] In the embodiment shown in FIG. 3 , the hollow regular tetrahedron is composed of six triangular prism units with cut corners, and the corner cut places at the top of every three units are bound into a standard regular tetrahedron by iron wire through the wire binding hole 2 . The triangular prism unit is made of C25 concrete pouring, and the cross section is an equilateral triangle with a side length of 30 cm; the length of the triangular prism unit is 300 cm. Each triangular prism unit 1 with chamfered corners reserves three groups of Y-shaped threading holes 2 before casting, and the diameter of the threading holes 2 is 3 cm. For the wound repair structure, 1 to 2 binding iron wires with a diameter of 9 mm are selected for the binding holes 2 at the top corners of every three units, and one is made to pass through the hole 2 for binding to form a hollow regular tetrahedral wound repair structure.

Embodiment 2

[0021] This embodiment is an extension of Embodiment 1. Bind a hollow regular tetrahedral concrete structure with one or several other hollow regular tetrahedral concrete structures, and use the above-mentioned binding iron wire to bind the wire hole 2 in the middle of any adjacent unit, so that the structure has the ability to connect and resist Greater breach velocity.

Embodiment 3

[0023] This embodiment is a modification of Embodiment 1. Connect the tops with cut corners of every two triangular prism units 1 with the thread-binding hole 2 in the middle of one triangular prism unit 1, and a total of six triangular prism units form a three-rod hexapod structure, which can be formed individually or collectively to form a wound repair structure .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com