Point light source reading laser encryption plastic film anticounterfeiting mark and preparation method thereof

An anti-counterfeiting mark and point light source technology, which is applied in the field of point light source reading laser encrypted plastic film anti-counterfeiting marks and its preparation, can solve the problems of loss of anti-counterfeiting ability, unfavorable promotion, and inability to distinguish true from false, etc., and achieve the convenience of authenticity query Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

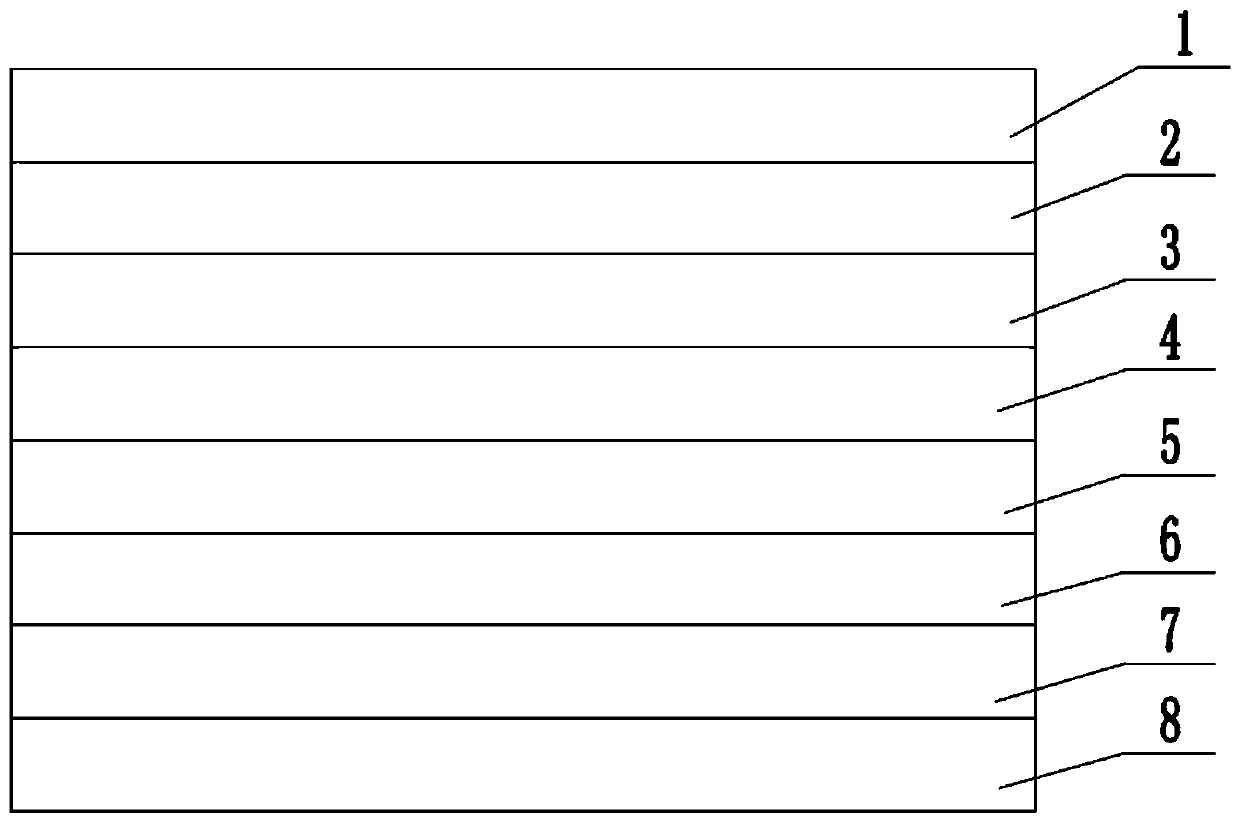

[0062] like figure 1 As shown, the point light source for reading the laser encrypted plastic film anti-counterfeiting label includes a PET layer 1, an imaging layer 2, a laser encrypted information layer 3, a replication layer 4, a printing layer 5, and a gravure layer connected in sequence from top to bottom. 6. A pressure-sensitive adhesive layer 7 and a silicone oil paper layer 8, hiding digital coded information in the laser encrypted information layer 3.

[0063] The PET layer 1 is a 20 μm single-sided corona PET film.

[0064] The PET layer 1 and the imaging layer 2 are inseparable.

[0065] The replication layer 4 is a UV varnish capable of replicating holographic patterns.

[0066] The thickness of the replication layer 4 is 5 μm.

[0067] The preparation method for reading the laser encrypted plastic film anti-counterfeiting mark with a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com