Intelligent harvester for dwarf close-planting fruit-bearing forests

A dwarf dense planting and harvesting machine technology, which is applied to harvesters, renewable energy machines, applications, etc., can solve the problems of missing and not being able to sort jujubes of different sizes and specifications, and achieve the effect of being easy to drop and not easy to miss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

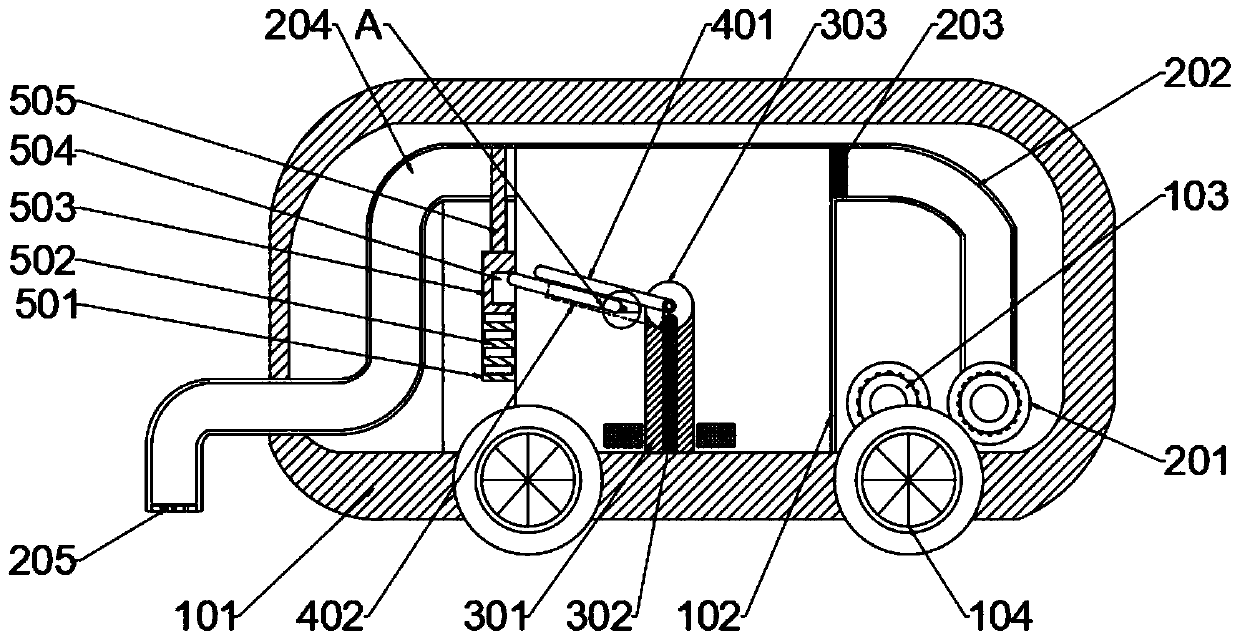

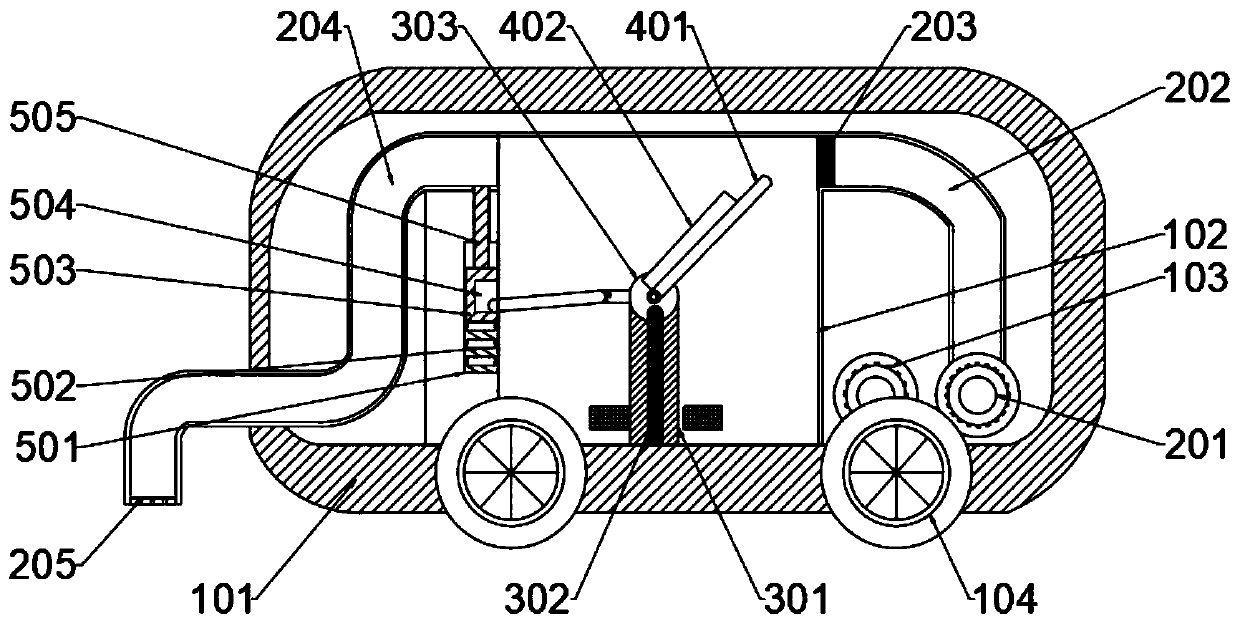

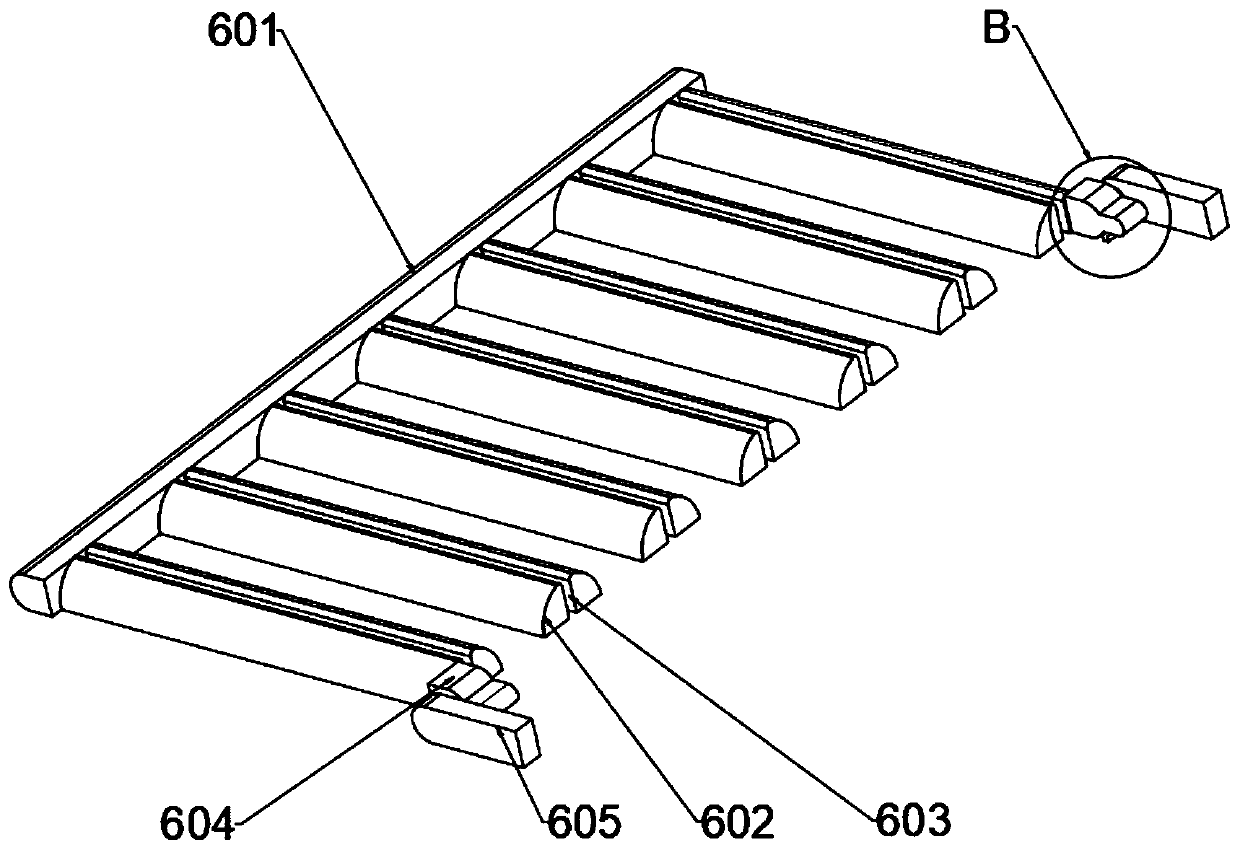

[0027] Example: such as Figure 1-7As shown, an intelligent harvester for dwarf densely planted fruit forests includes a support assembly, a suction assembly, a separation assembly, a separation assembly, a linkage assembly, and a supporting assembly. The supporting component is equipped with a suction component inside, and the suction component plays the role of sucking the red dates on the bottom surface into the device. There is a separation component on the top of the component. The separation component plays the role of separating jujubes of different sizes. There is a linkage component on one side of the separation component. The linkage component plays the role of controlling the suction of the device. Force component, the support force component plays the effect of temporarily supporting the jujube that enters this device inside.

[0028] Support assembly comprises support housing 101, jujube storage box 102, motor 103, wheel 104, and support housing 101 is positioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com