Filter disc device of horizontal filter

A filter, horizontal technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of filling, failure to achieve anti-sticking effect, clogging, etc., to achieve a wide application field, surface Reduced risk of scaling, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the characteristics and technical content of the present invention in more detail, the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The attached drawings are only for reference and description, and are not intended to limit the present invention.

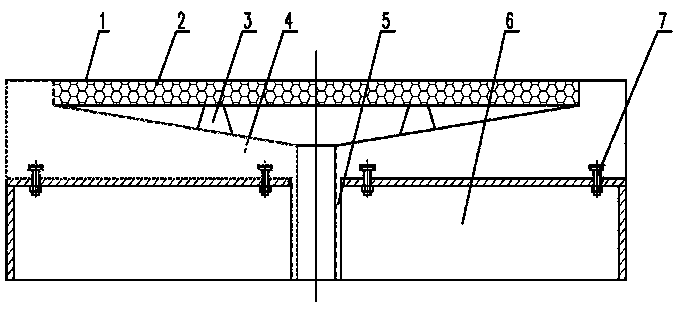

[0026] refer to figure 1 A filter disc device for a horizontal filter, comprising: a filter cloth 1, a filter screen 2, a filter screen support 3, a filter bucket 4, a connecting pipe 5, a filter disc steel frame 6, and a connecting device 7. The filter cloth 1 is installed above the filter screen 2, the filter screen support 3 is connected below the filter screen 2, the filter bucket 4 is connected to the filter screen support 3, the connecting pipe 5 is installed in the middle of the filter bucket 4, The filter disc steel frame 6 is connected to the filter bucket 4 through a connecting device 7 .

[0027] The filtrate is filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com