Novel full-automatic carbon forming equipment and working method thereof

A molding equipment, fully automatic technology, applied in the direction of molding pressure head, manufacturing tools, supply devices, etc., can solve the problems of low density of carbon particles, high equipment investment, bulky volume, etc., to achieve high product density and automation High degree of effect with low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

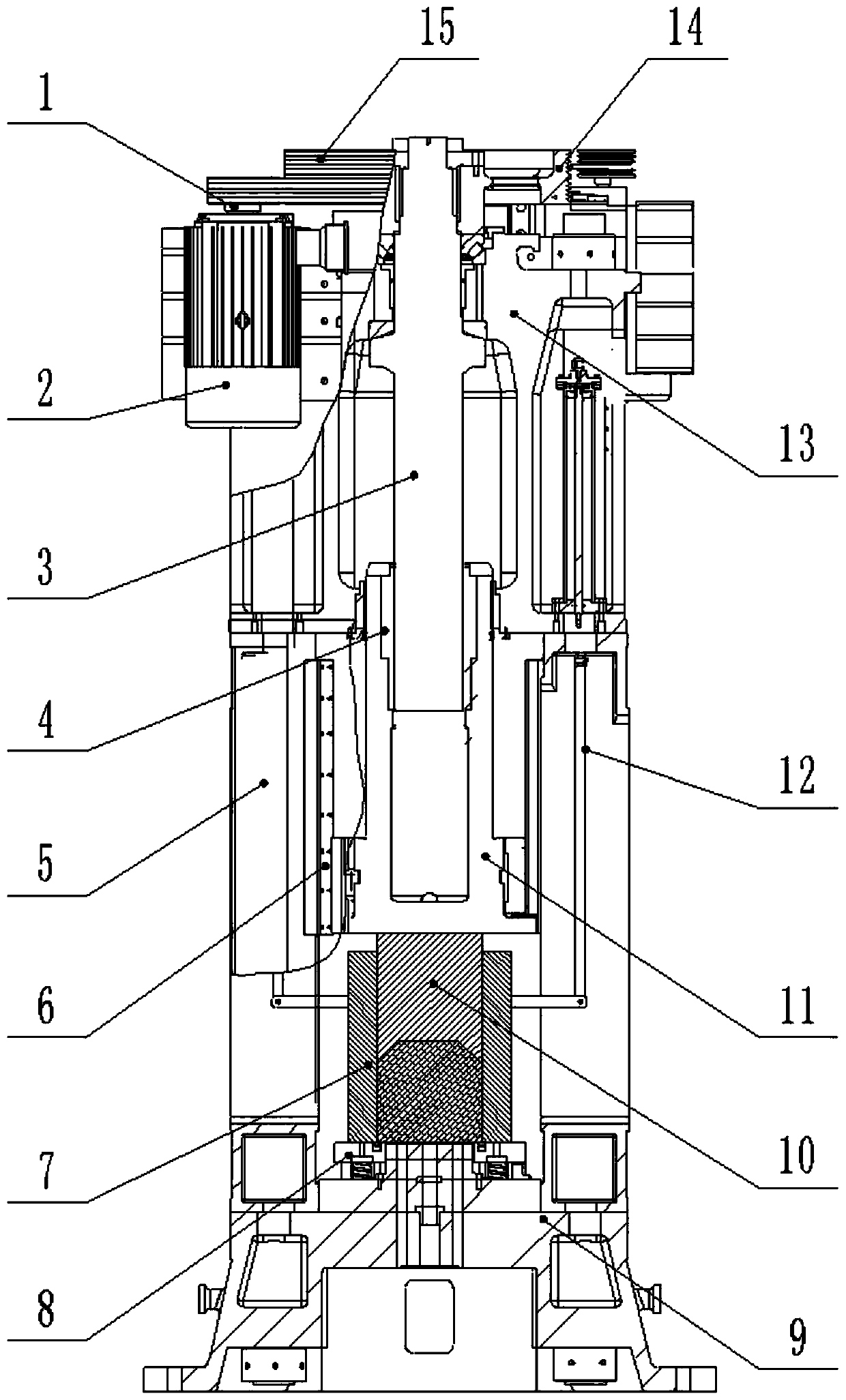

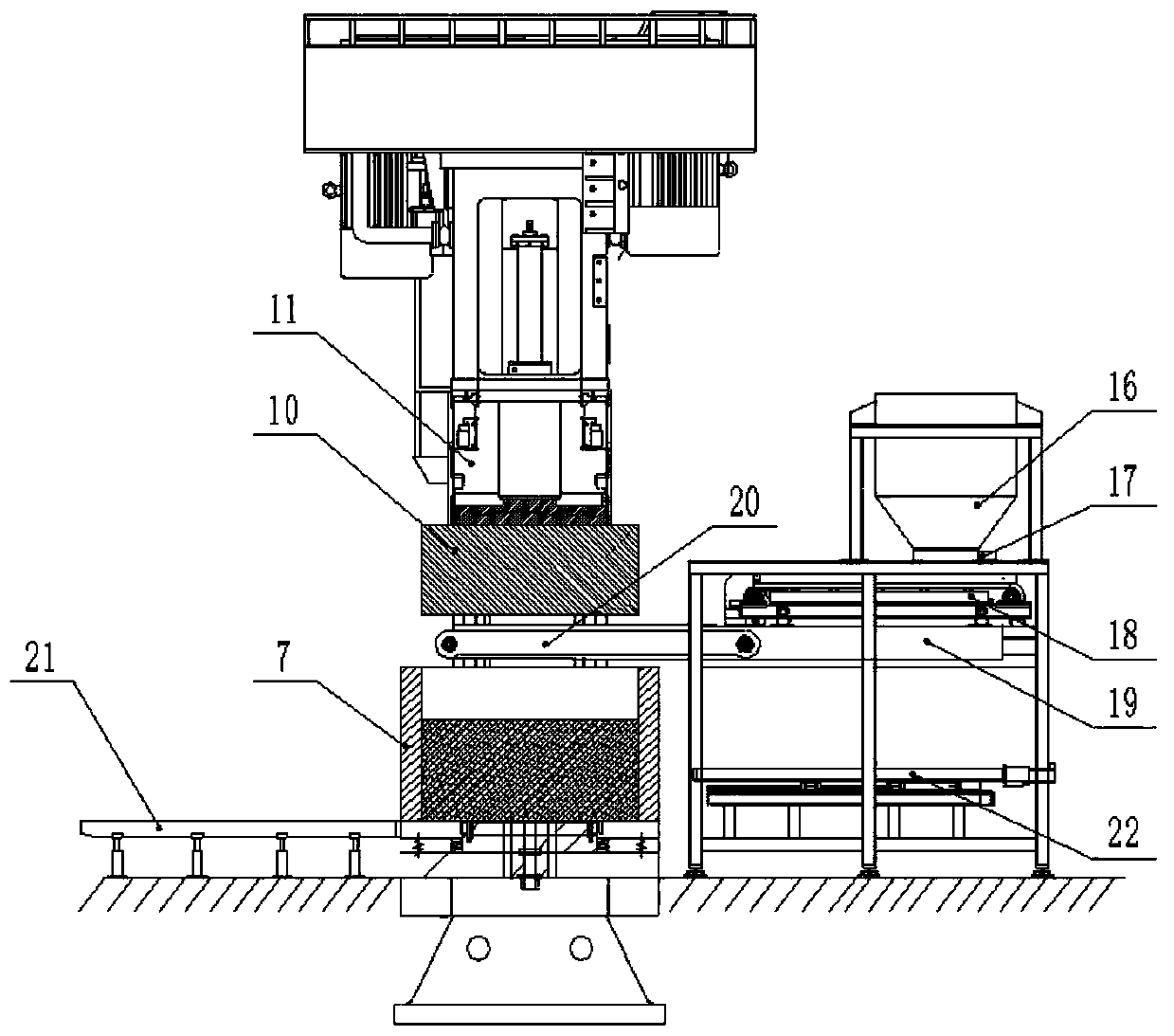

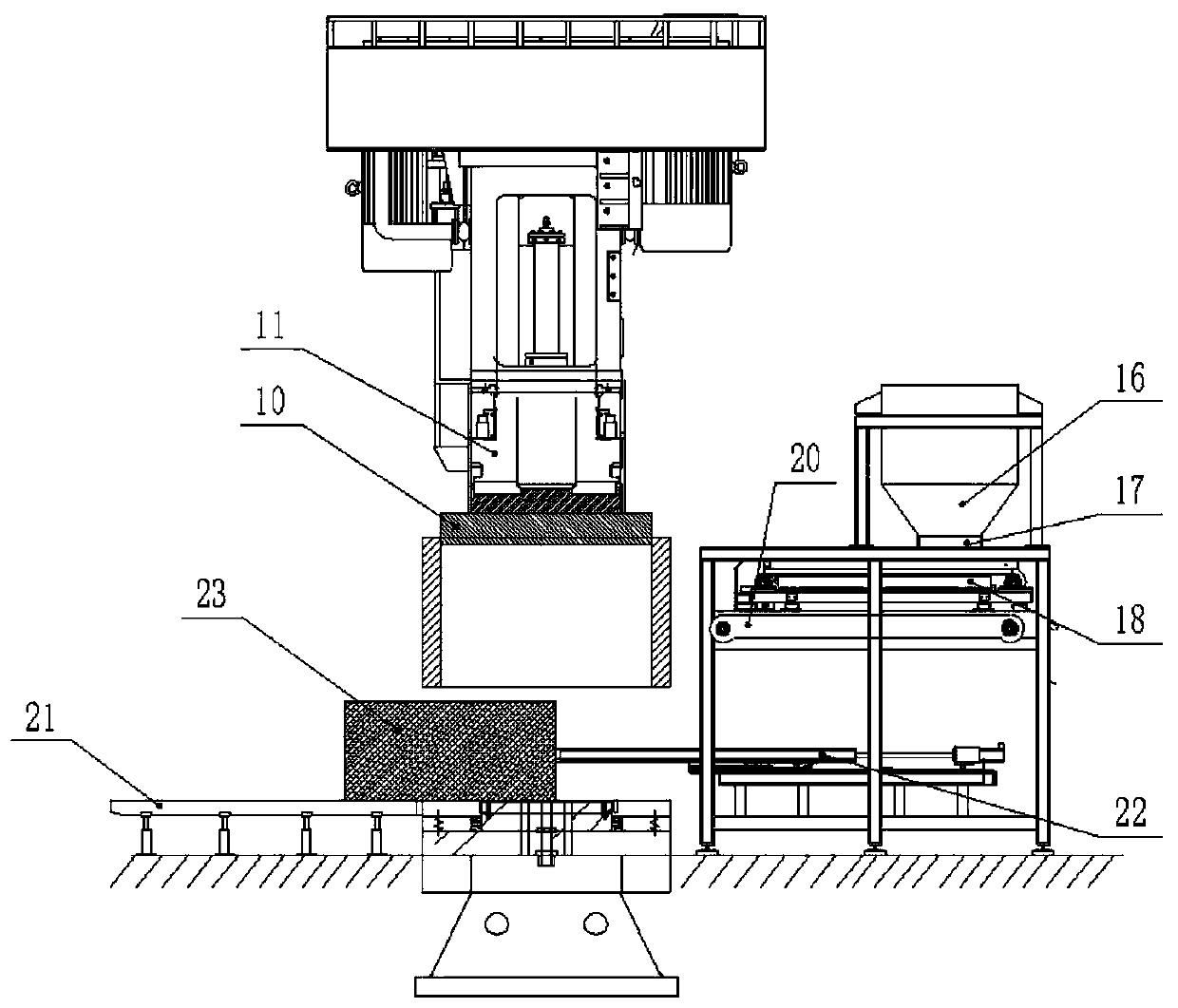

[0046] Such as figure 1 As shown, a new type of fully automatic carbon molding equipment includes a molding machine and an automatic weighing cloth pushing brick machine. The molding machine includes a frame, a large pulley 14, a small pulley 1, a screw 3, a slider 4, and a frame It consists of an upper beam 13, a column 5 and a base 9.

[0047] Drive motor 2 is installed on the upper beam 13, and small pulley 1 is installed on the drive motor 2.

[0048] The screw rod 3 is installed in the upper beam 13 through a thrust bearing and can rotate. The top of the screw rod 3 is equipped with a large pulley 14. The driving motor 2 drives the small pulley 1. The small pulley 1 drives the large pulley 14 through the belt 15 for reciprocating rotation. .

[0049] Large belt pulley 14 is connected with screw rod 3 by positioning pin, drives screw rod 3 to rotate wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com