Control device, system and method for preventing lubricating oil of air compressor from being emulsified

A control device and air compressor technology, applied in the field of rail transit, can solve problems such as increasing operating costs, shortening the service life of air compressors, and poor emulsification of lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

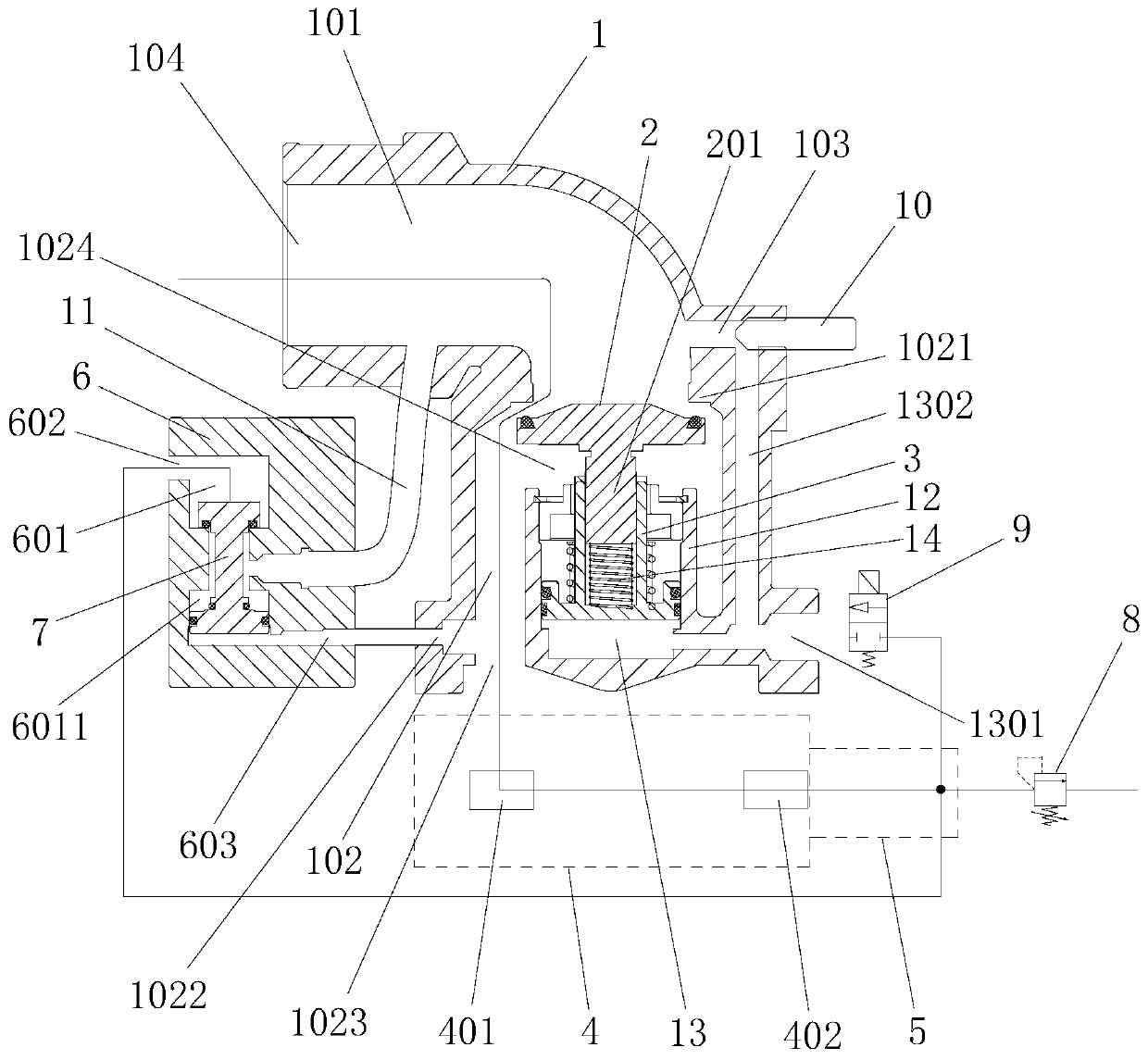

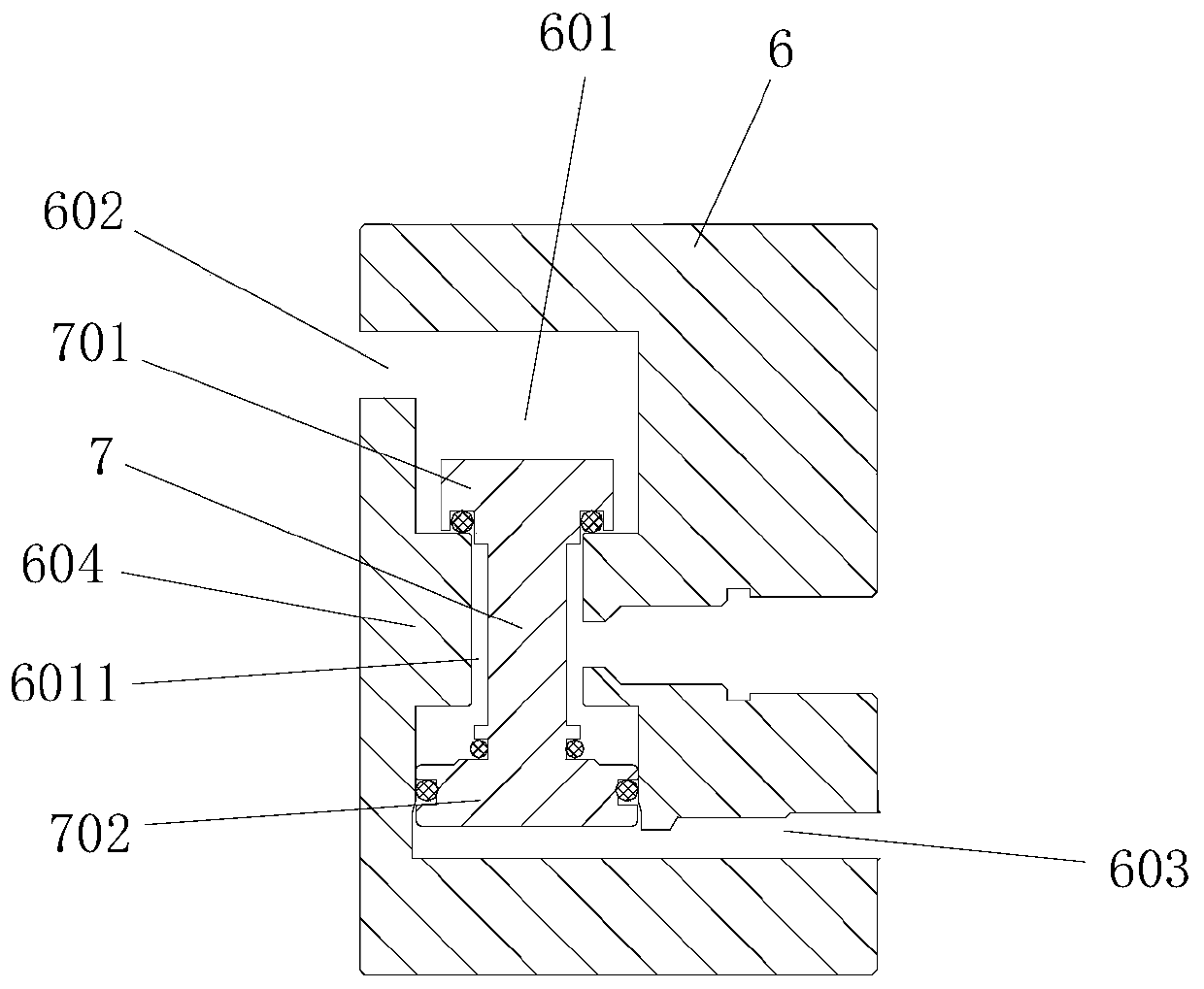

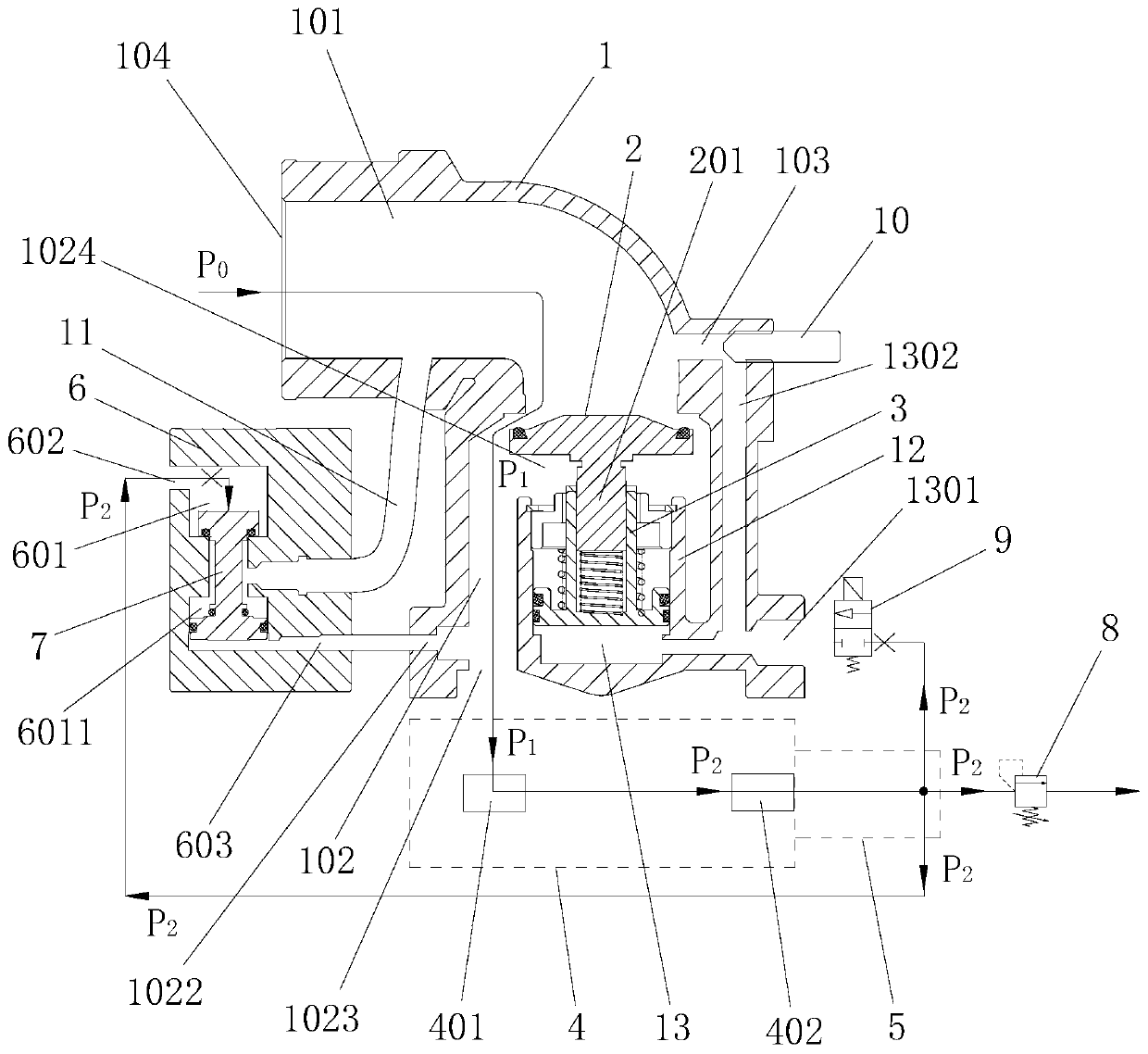

[0091] Such as figure 1As shown, the present invention provides a control device for preventing the emulsification of the lubricating oil of the air compressor, and the control device for preventing the emulsification of the lubricating oil of the air compressor is connected to the low-pressure air inlet of the air compressor. The control device for preventing air compressor lubricating oil emulsification includes an intake valve main body 1 and an unloading valve main body 6, wherein a first accommodating chamber 601 is formed inside the unloading valve main body 6, and on the upper part of the unloading valve main body 6 There is a first opening 602 communicating with the first accommodation chamber 601, and a second opening 603 communicating with the first accommodation chamber 601 is opened at the lower part of the unloading valve body 6, and the first accommodation chamber 601 is provided with There is a spool 7 that can move up and down; the inside of the intake valve bo...

Embodiment approach 2

[0107] Such as Figure 7 As shown, the present invention provides a control system for preventing air compressor lubricating oil emulsification, the control system for preventing air compressor lubricating oil emulsification includes a main air compressor 20, an auxiliary air compressor 30 and two above-mentioned prevention air compressors The control device 40 for the emulsification of the compressor lubricating oil, a control device 40 for preventing the emulsification of the air compressor lubricating oil is arranged on the main air compressor 20, and is connected with the main air compressor 20; another control device for preventing the emulsification of the air compressor lubricating oil The control device 40 is arranged on the auxiliary air compressor 30 and connected with the auxiliary air compressor 30 .

[0108] The characteristics and advantages of the control system for preventing air compressor lubricating oil emulsification of the present invention are:

[0109] ...

Embodiment approach 3

[0111] Such as Figure 8 As shown, the present invention provides a control method for preventing the emulsification of the lubricating oil of the air compressor, and the control method for preventing the emulsification of the lubricating oil of the air compressor is suitable for the control system for preventing the emulsification of the lubricating oil of the air compressor in the second embodiment. The control method to prevent the emulsification of air compressor lubricating oil includes the following steps:

[0112] Step S1: Confirm that the main air compressor 20 is in normal working state. If the main air compressor 20 is in normal state, only the main air compressor 20 is allowed to enter the idling state; if the main air compressor 20 cannot be started due to a fault, the auxiliary air compressor 30 to replace the main air compressor 20, allowing the auxiliary air compressor 30 to enter the idling state;

[0113] Step S2: After the vehicle is powered on, monitor the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com