In-situ self-stabilized solid oxide fuel cell cathode, cell and preparation method thereof

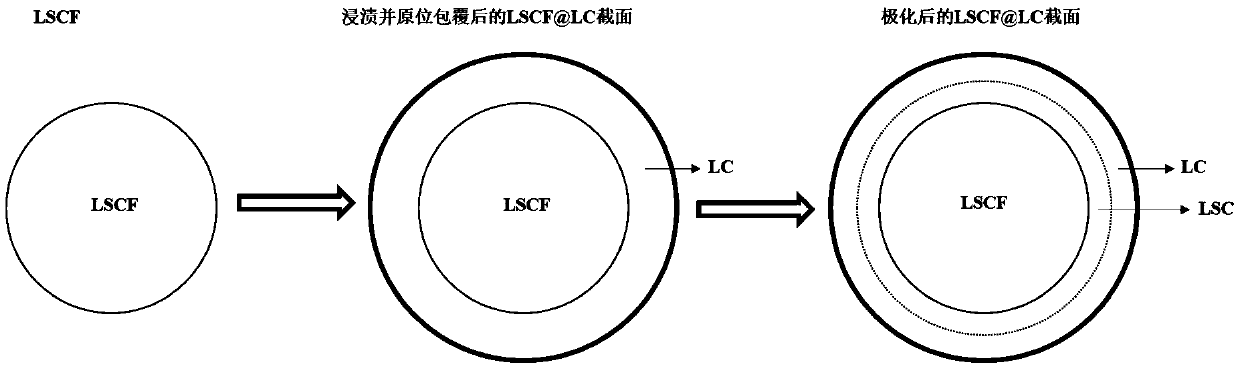

A fuel cell cathode, solid oxide technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of LSCF modification difficult to promote the industrialization process, etc., and achieve long-term working stability, low phase formation temperature, ORR Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] LSCF powder preparation steps are as follows:

[0048] Dissolve the stoichiometric metal nitrate in deionized water, and prepare the precursor solution according to the molar ratio of metal ion: EDTA: citric acid of 1:1:1.5. After the precursor solution is dissolved and clarified, add ammonia water to adjust the pH value to 8 , stirred in an oil bath at 70°C until a viscous gel was formed, and then placed in an oven at 200°C for 14 hours to form a porous precursor. Grind the precursor evenly and calcined at 750°C for 5 hours to obtain LSCF powder. The powder after the phase is subjected to ball milling and flotation treatment to obtain nano-scale LSCF cathode powder, and the above-mentioned LSCF powder and carbon powder are added to a binder according to a certain solid content ratio to grind into a cathode slurry, and screened Printed onto the surface of the dense GDC electrolyte and sintered at 1100°C to form a porous LSCF framework.

[0049] The steps of coating the...

Embodiment 2

[0055] LSCF powder preparation steps are as follows:

[0056] Dissolve the stoichiometric metal nitrate in deionized water, and prepare the precursor solution according to the molar ratio of metal ion: EDTA: citric acid of 1:1:1.5. After the precursor solution is dissolved and clarified, add ammonia water to adjust the pH value to 9 , stirred in an oil bath at 90°C until a viscous gel was formed, and then placed in an oven at 160°C for 10 hours to form a porous precursor. Grind the precursor evenly and calcined at 850°C for 3 hours to obtain LSCF powder. The powder after the phase is subjected to ball milling and flotation treatment to obtain nano-scale LSCF cathode powder, and the above-mentioned LSCF powder and carbon powder are added to a binder according to a certain solid content ratio to grind into a cathode slurry, and screened Printed onto the surface of the dense GDC electrolyte and sintered at 900°C to form a porous LSCF framework.

[0057] The steps of coating the ...

Embodiment 3

[0063] LSCF powder preparation steps are as follows:

[0064] Dissolve the stoichiometric metal nitrate in deionized water, and prepare the precursor solution according to the molar ratio of metal ion: EDTA: citric acid of 1:1:1.5. After the precursor solution is dissolved and clarified, add ammonia water to adjust the pH value to 8.5 , stir in an oil bath at 80°C until a viscous gel is formed, then place it in an oven at 180°C for 12 hours to form a porous precursor, grind the precursor evenly, and calcinate at 800°C for 4 hours to obtain LSCF powder. The powder after the phase is subjected to ball milling and flotation treatment to obtain nano-scale LSCF cathode powder, and the above-mentioned LSCF powder and carbon powder are added to a binder according to a certain solid content ratio to grind into a cathode slurry, and screened Printed onto the surface of the dense GDC electrolyte and sintered at 1000°C to form a porous LSCF framework.

[0065] The steps of coating the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com