Dental implant

A technology of dental implants and body, applied in dentistry, dental implants, dental restorations, etc., can solve problems such as insufficient depth of bone ingrowth, failure to ensure stability, and loosening of implants, so as to achieve stable retention, The effect of ensuring correct installation and reducing the loosening rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

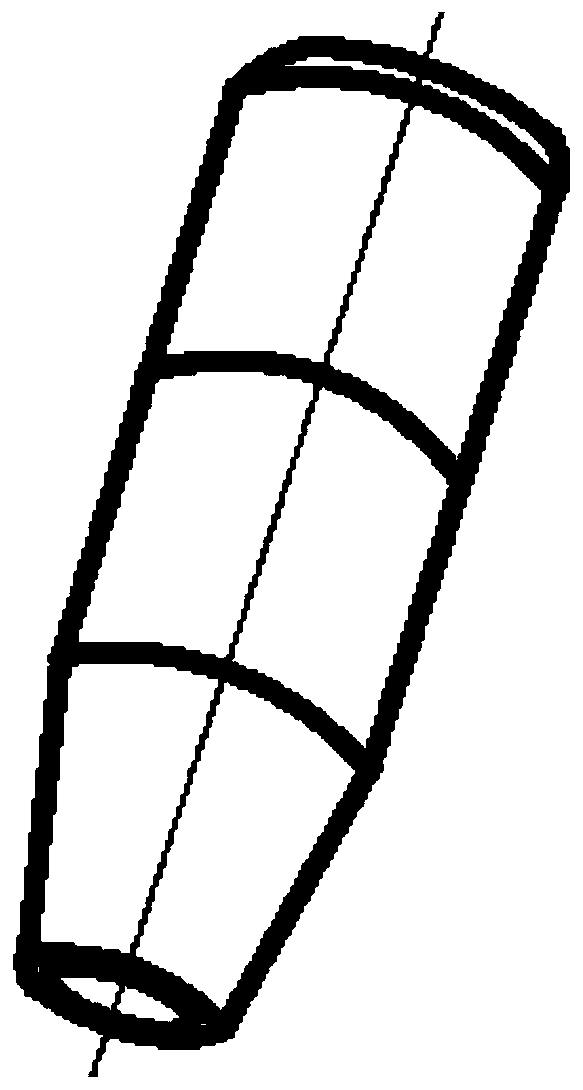

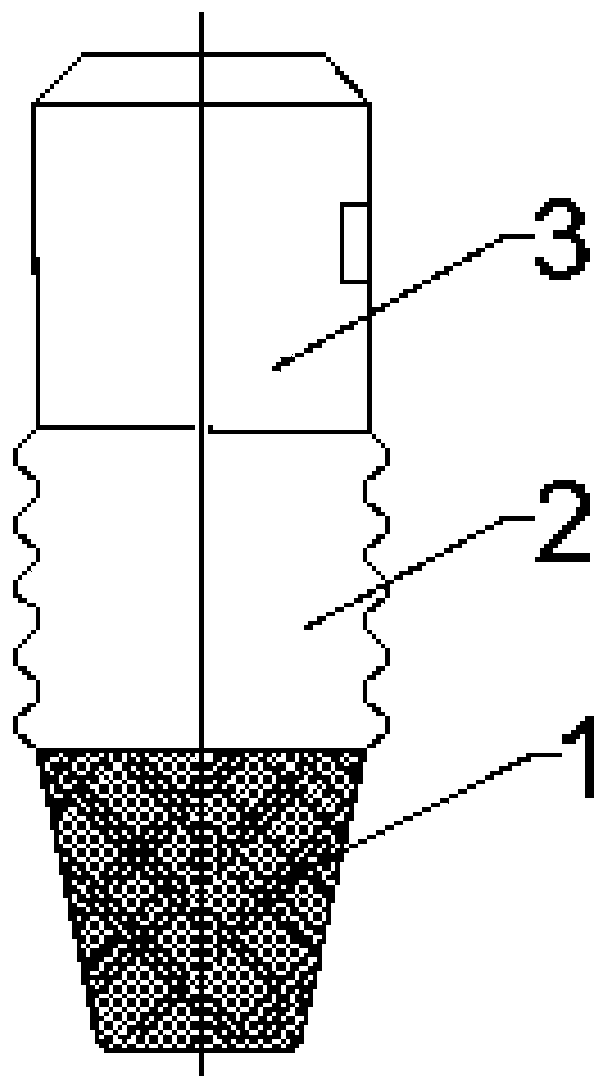

[0027] Please refer to the attached Figure 1-2 , the purpose of this embodiment is to provide a dental implant, a dental implant comprising: a dental implant body, the dental implant body has a root 1 , a bottom 2 and an end 3 .

[0028] Specifically, the root 1 has a conical structure, which can better match the structural features of the alveolar bone. The material of the root 1 of the dental implant body is tantalum metal, and the outer surface of the root 1 is provided with a bone trabecular structure. The porosity of the bone trabecular structure is 75%. The wire diameter of the structure is 400 μm, and the pore size of the trabecular bone structure is 600 μm. The trabecular bone structure can improve the biocompatibility of dental implants, optimize the overall performance of dental implants, increase the contact area with normal bone through the pores on the surface of trabecular bone, provide space for bone ingrowth, and speed up clinical The speed of osseointegrati...

Embodiment 2

[0032] Please refer to the attached Figure 1-2 , the purpose of this embodiment is to provide a dental implant, a dental implant comprising: a dental implant body, the dental implant body has a root 1 , a bottom 2 and an end 3 .

[0033] Specifically, the root 1 has a conical structure, which can better match the structural features of the alveolar bone. The material of the root 1 of the dental implant body is tantalum metal, and the outer surface of the root 1 is provided with a bone trabecular structure. The porosity of the bone trabecular structure is 85%. The wire diameter of the beam structure is 400 μm, and the pore size of the trabecular bone structure is 600 μm. The trabecular bone structure can improve the biocompatibility of dental implants, optimize the overall performance of dental implants, increase the contact area with normal bone through the pores on the surface of trabecular bone, provide space for bone ingrowth, and speed up clinical The speed of osseointe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com