Whitening mud mask with pure natural components and preparation process of whitening mud mask

A mud mask, pure natural technology, applied in the field of cosmetics, can solve problems such as poor crushing effect, irritation, facial skin damage, etc., and achieve the effects of simple extraction process, reduction of production cost, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

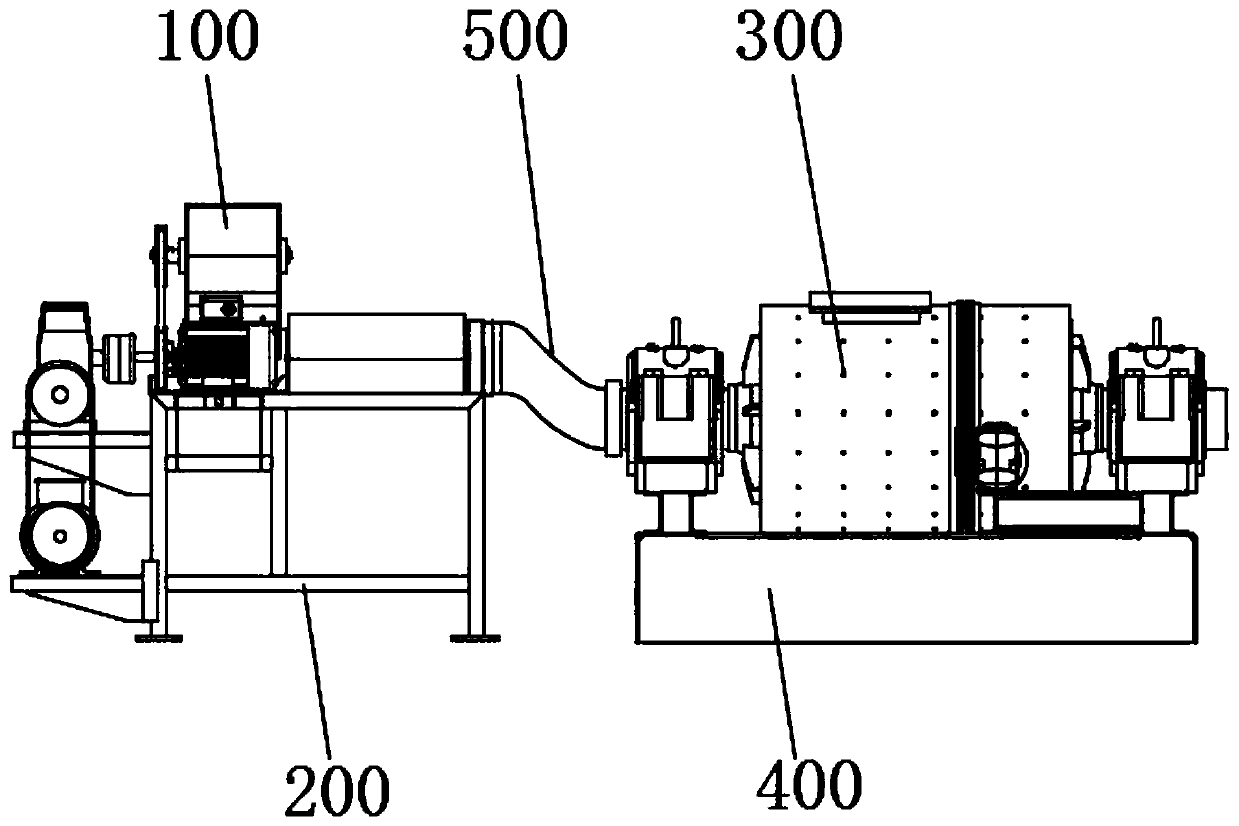

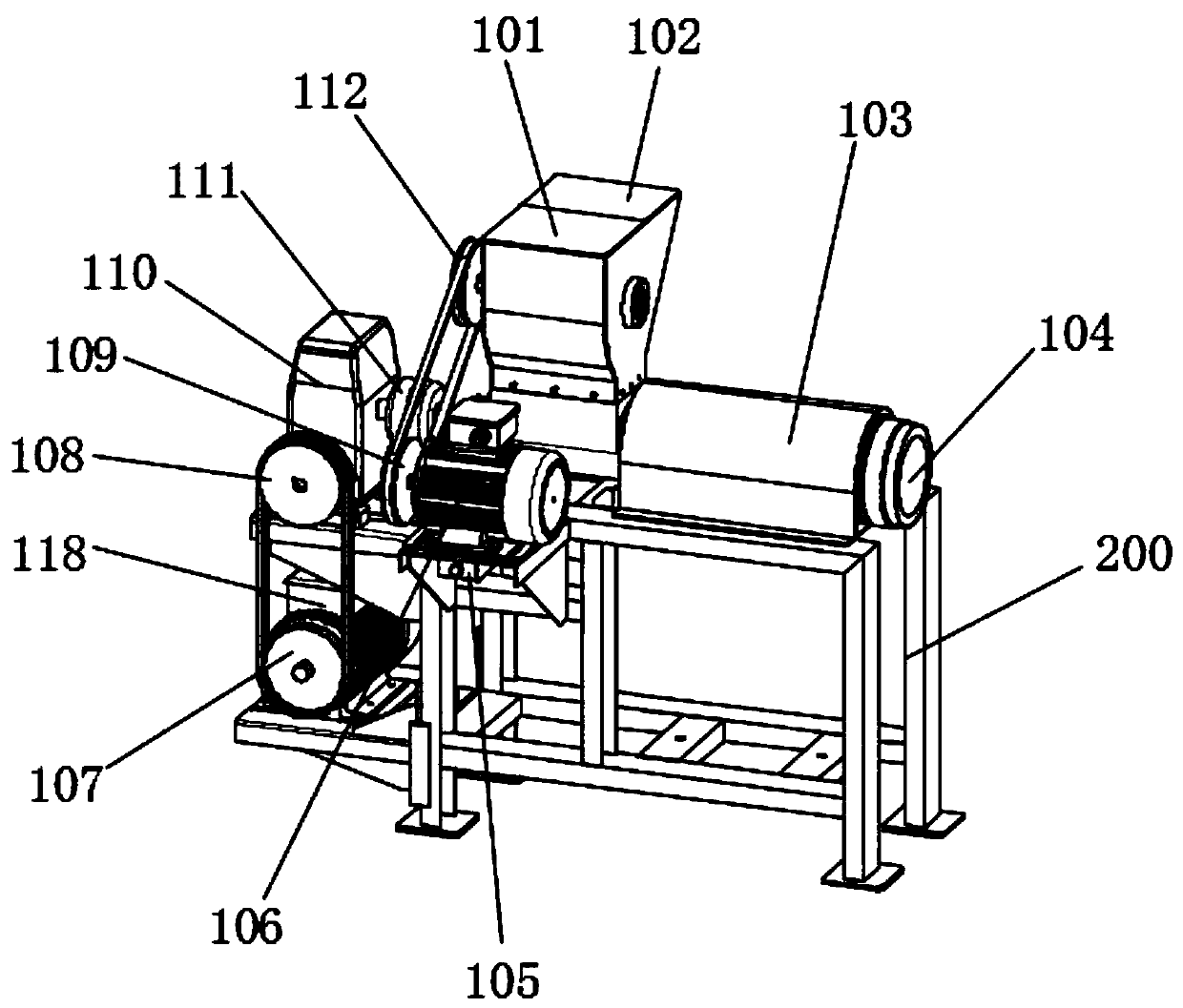

[0051] see Figure 1-8 As shown, this embodiment is a whitening mud mask with pure natural ingredients, which is made from the following components in parts by weight: 30 parts of barley, 12 parts of motherwort, 12 parts of seaweed mud, 10 parts of papaya, and 10 parts of bletilla striata 10 parts of coconut oil and 50 parts of deionized water;

[0052] The whitening mud mask is prepared by the following steps:

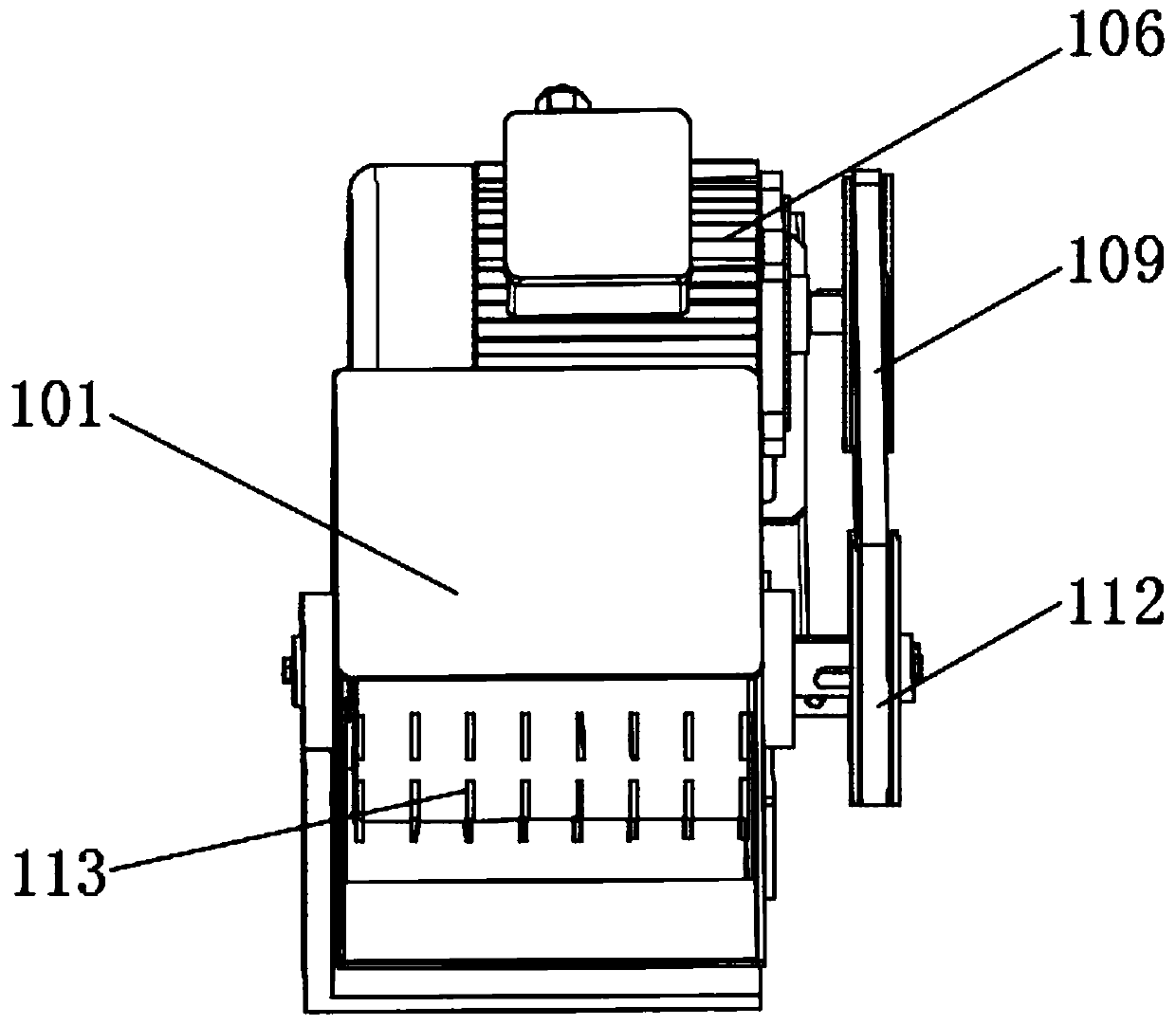

[0053] Step 1. Preparation of the first extract: after the barley is superfinely pulverized, mixed with an aqueous ethanol solution with a concentration of 30%, and then extracted in an environment mixed with nitrogen, and the condensate is collected to obtain the first extract;

[0054] Step 2. Preparation of the second extract: take fresh motherwort, papaya and bletilla striata and grind them, add a 30% ethanol aqueous solution solvent, soak for 10-30 minutes, remove the solvent, and perform extraction. At the same time, microwave radiation is used for auxiliary ex...

Embodiment 2

[0072] see Figure 1-8 As shown, the present embodiment is a whitening mud mask with pure natural ingredients, which is made from the following components in parts by weight: 50 parts of barley, 16 parts of motherwort, 15 parts of seaweed mud, 15 parts of papaya, and 15 parts of bletilla striata 15 parts of coconut oil and 70 parts of deionized water;

[0073] The whitening mud mask is prepared by the following steps:

[0074]Step 1. Preparation of the first extract: after the barley is superfinely pulverized, mixed with an aqueous ethanol solution with a concentration of 70%, and then extracted in an environment mixed with nitrogen, and the condensate is collected to obtain the first extract;

[0075] Step 2. Preparation of the second extract: take fresh motherwort, papaya and bletilla striata and grind them, add a 60% ethanol aqueous solution solvent, soak for 10-30 minutes, remove the solvent, and extract, and use microwave radiation to assist extraction, and the extractio...

experiment example 1

[0093] Experiment method 1: Use a dark container bottle for storage, and place it naked in an environment with an ambient temperature of 35°C and a relative humidity of 75%. Continuously observe and test to detect changes in color, microbial content, and pH value. Specific inspection items and inspection methods And testing standards are carried out in accordance with QB / T2872-2007 mask.

[0094] Experiment method 2: Skin smoothness test: choose 100 young women aged 20-40, in good health, without any history of skin diseases and allergies, with non-sensitive skin, who can use cosmetics according to the standard, and test the skin brightness of the face after 1 month of trial White value (average value), smoothness (average value), comprehensive brightness rate (average value), spot occupancy rate (average value), and compare the results before and after the trial.

[0095] Before trial: Facial skin brightening value (average): 70.21, smoothness (average): 0.89, comprehensive b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com