Double-sided spot welding system

A double-sided spot welding and spot welding technology, which is applied in the field of parts welding, can solve the problems of difficult gripping by manipulators, high manual labor intensity, high production and maintenance costs, and achieve low operating and maintenance costs, reduced investment costs, and labor costs. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

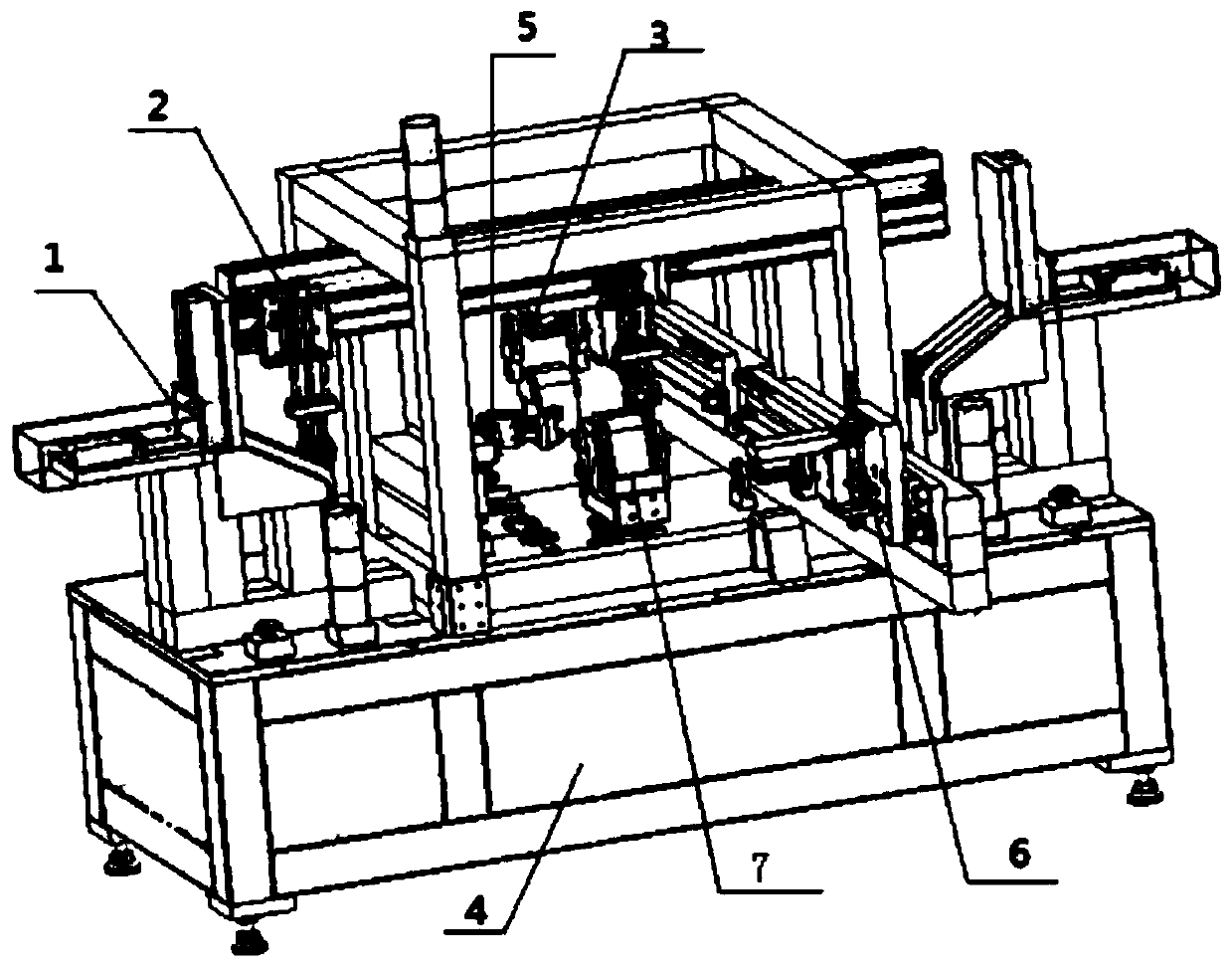

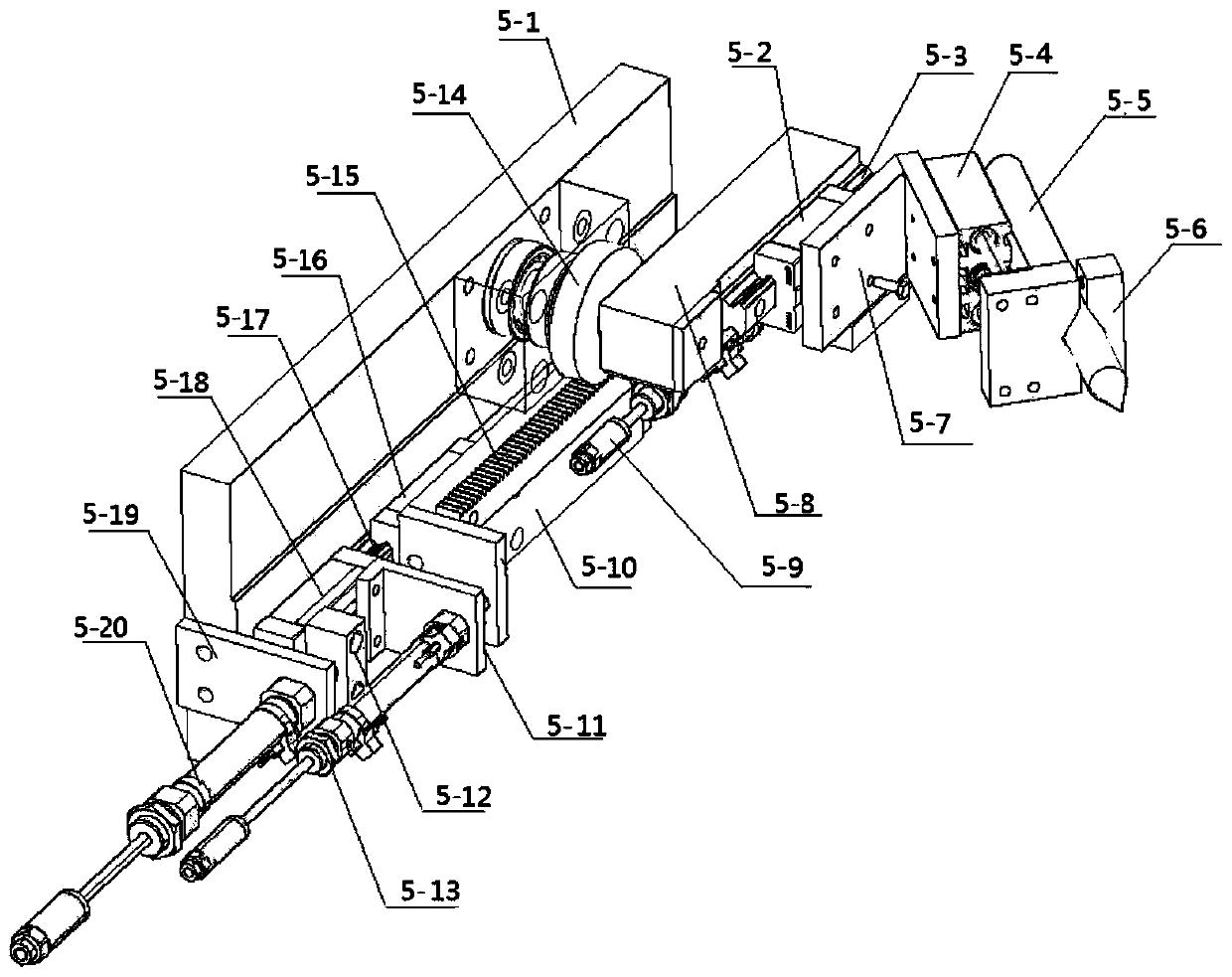

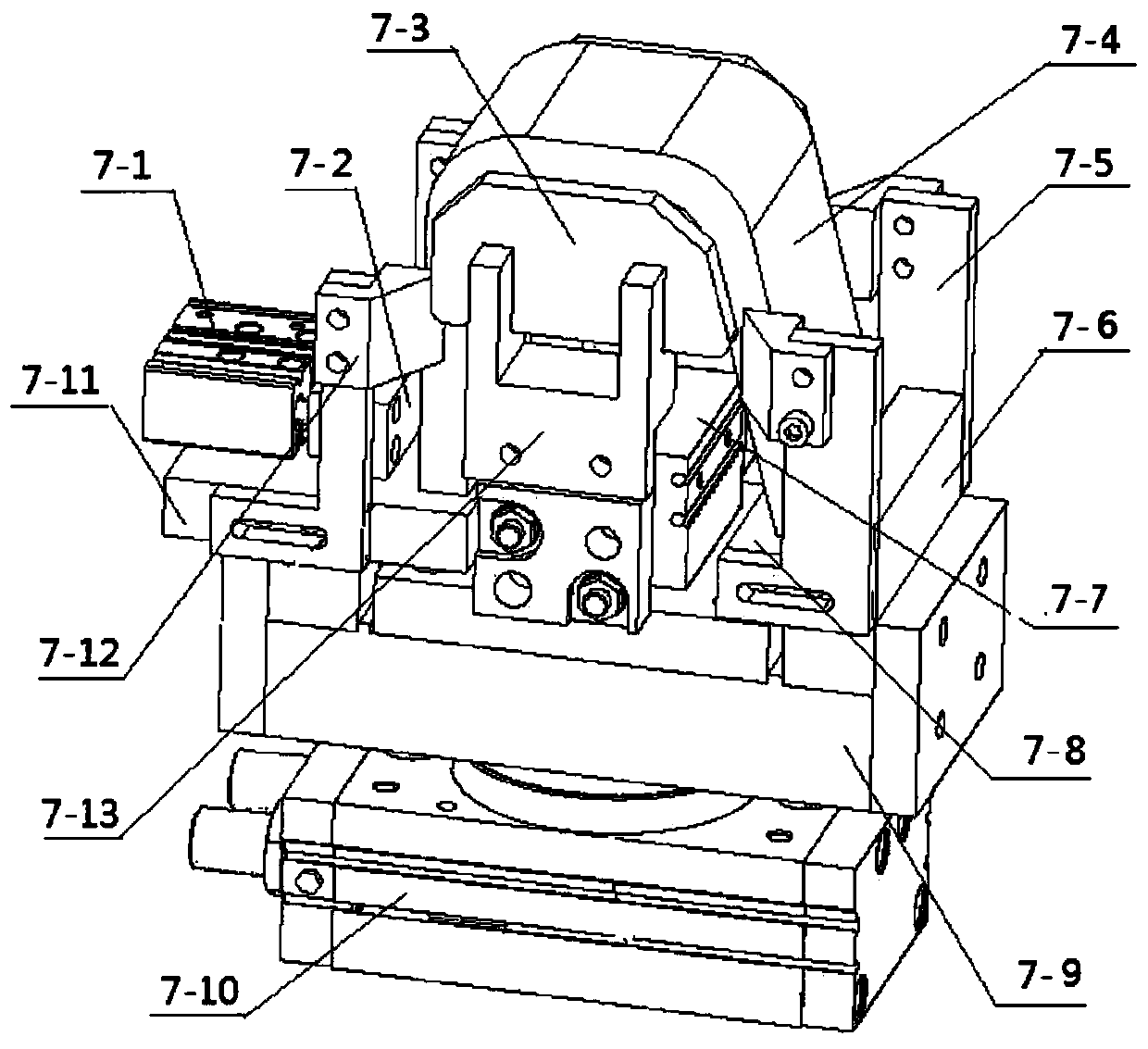

[0030] A double-sided spot welding system, comprising a U-shaped plate feeding conveyor belt, two side plate feeding devices 1, a side plate feeding manipulator 2, a spot welding main machine, and a blanking manipulator 3. The spot welding main machine is fixed On an operating cabinet 4, the left and right sides of the spot welding main frame are symmetrically fixed on both sides of the plate feeding device, and the side plate feeding manipulator is fixed on the spot welding main frame between the two sides of the plate feeding device. The place ahead of spot-welding main frame installs U-shaped plate feeding conveyor belt, installs U-shaped plate feeding manipulator 6 above the end section of U-shaped plate feeding conveying belt, and instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com