Stacker-reclaimer remote monitoring and management system based on Internet technology and method

A management system and remote monitoring technology, applied in the field of stackers and reclaimers, can solve the problems of equipment work efficiency reduction, equipment shutdown, and long production cycle of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

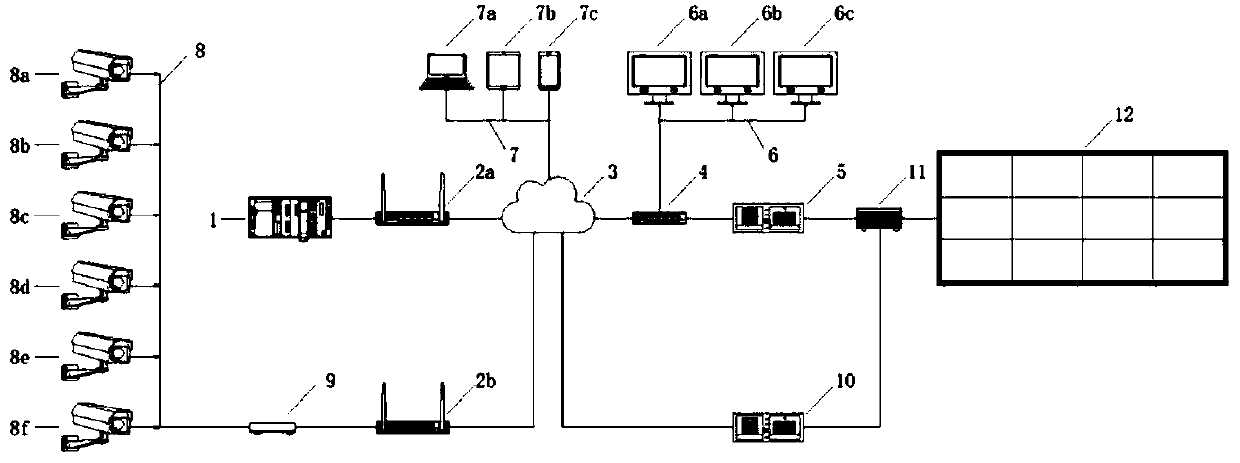

[0050] refer to figure 1 , the remote monitoring and management system of the stacker-reclaimer based on Internet technology of the present invention includes: a stacker-reclaimer PLC control system 1, an industrial-grade 4G wireless router 2a, a remote data cloud server 5, an engineer station 6, and an intelligent monitoring terminal 7.

[0051] Among them, the stacker-reclaimer PLC control system 1 is connected to the industrial-grade 4G wireless router 2; the industrial-grade 4G wireless router 2 is connected to the remote data cloud server 5 through the Internet 3; the engineer station 6 is connected to the remote data cloud server 5 through the switch 4 connected;

[0052] The connection communication network of the stacker-reclaimer remote monitoring and management system based on Internet technology includes industrial Ethernet, industrial field bus and industrial-grade 4G wireless router 2.

[0053] It should be noted that: since there are many connecting devices in t...

Embodiment 2

[0067] The present invention provides a control method of a stacker-reclaimer remote monitoring and management system based on Internet technology, which specifically includes the following steps:

[0068] Step S1: use the PLC control system 1 of the stacker-reclaimer to connect to the industrial-grade 4G wireless router 2; the industrial-grade 4G wireless router 2 is connected to the data cloud server 5 through the Internet 3; the data cloud server 5 is connected to the engineer station through the switch 4 6-phase connection;

[0069] Step S2: Use the remote data cloud server of the data cloud server 5 to be responsible for the connection and communication of data and video, the receiving and sending of information, and the establishment of communication connections within the system, wherein the data cloud server 5 receives the original data of various institutions on the bucket wheel machine site Information, data information on the status of electrical components and data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com