A kind of heat-resistant high-strength spring steel and its production method

A production method and high-strength technology, applied in the field of metal smelting, can solve problems such as changing properties, and achieve the effects of promoting precipitation, increasing strength, and increasing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

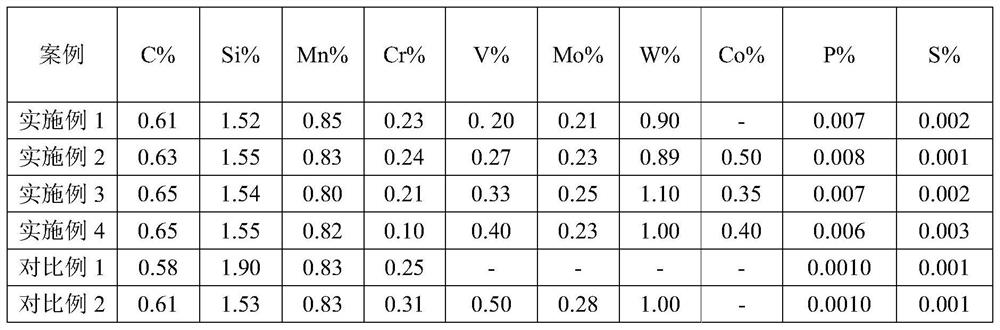

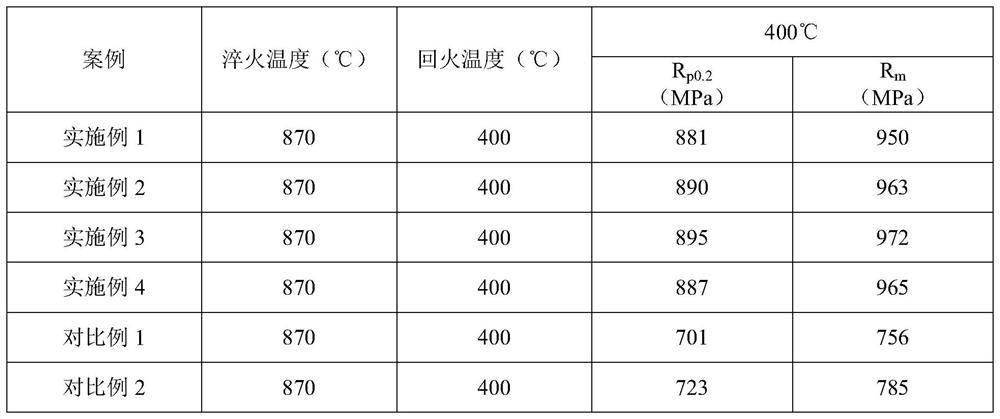

Embodiment 1

[0058] The production process of the heat-resistant high-strength spring steel in this embodiment is: electric arc furnace smelting→LF furnace refining→RH or VD vacuum degassing→round billet continuous casting→square billet rolling→flaw detection, grinding→excellent rod heating furnace heating →Controlled rolling and controlled cooling→Round steel finished product→Round steel quenching and tempering treatment.

[0059] Wherein, the heating temperature of the excellent rod heating furnace is 980-1070°C, preferably 1020-1050°C, and the time for the billet in the furnace is ≤170min, preferably 140-160min. Controlled rolling and controlled cooling adopts KOCKS controlled rolling and controlled cold rolling. When rolling round steel, the starting rolling temperature is 880-945°C, preferably 900-920°C; the finishing rolling temperature is 780-840°C, preferably 800-820°C. The hot-rolled round steel adopts the following quenching and tempering heat treatment process: quenching at 870...

Embodiment 2

[0063] The spring steel of this embodiment and its production method are basically the same as in Embodiment 1, except that the chemical composition of the spring steel of this embodiment is: C 0.63%, Si 1.55%, Mn 0.83%, Cr 0.24%, V 0.27% , Mo 0.23%, W0.89%, Co 0.50%, P 0.008%, S 0.001%, and the rest are Fe and other unavoidable impurities. In this embodiment, when heating with an excellent rod heating furnace, the heating temperature is controlled at 1030° C., and the billet stays in the furnace for 145 minutes. When rolling round steel, the starting rolling temperature is 910°C; the final rolling temperature is 810°C. The heat treatment process is: 870°C quenching (oil cooling), quenching medium temperature 20°C, 400°C tempering (air cooling). After heat treatment, the structure is tempered troostite.

Embodiment 3

[0065] The spring steel of this embodiment and its production method are basically the same as in Embodiment 1, the difference being that the chemical composition of the spring steel of this embodiment is: C 0.65%, Si 1.54%, Mn 0.80%, Cr 0.21%, V 0.33% , Mo 0.25%, W1.10%, Co 0.35%, P 0.007%, S 0.002%, and the rest are Fe and other unavoidable impurities. In this embodiment, when heating with an excellent rod heating furnace, the heating temperature is controlled at 1040° C., and the billet stays in the furnace for 150 minutes. When rolling round steel, the starting rolling temperature is 915°C; the final rolling temperature is 815°C. The heat treatment process is: 870°C quenching (oil cooling), quenching medium temperature 30°C, 400°C tempering (air cooling). After heat treatment, the structure is tempered troostite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com