Gas detection device and method for drilling fluid in riser pipe

A gas detection and riser technology, which is used in measuring devices, surveying, earthwork drilling, etc., can solve the problem of inability to achieve real-time data transmission, poor use effect, and the inability to meet the requirements of low gas intrusion monitoring by Doppler measurement technology, etc. problems, to achieve the effect of ensuring accuracy and reliability, improving accuracy and reliability, and improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

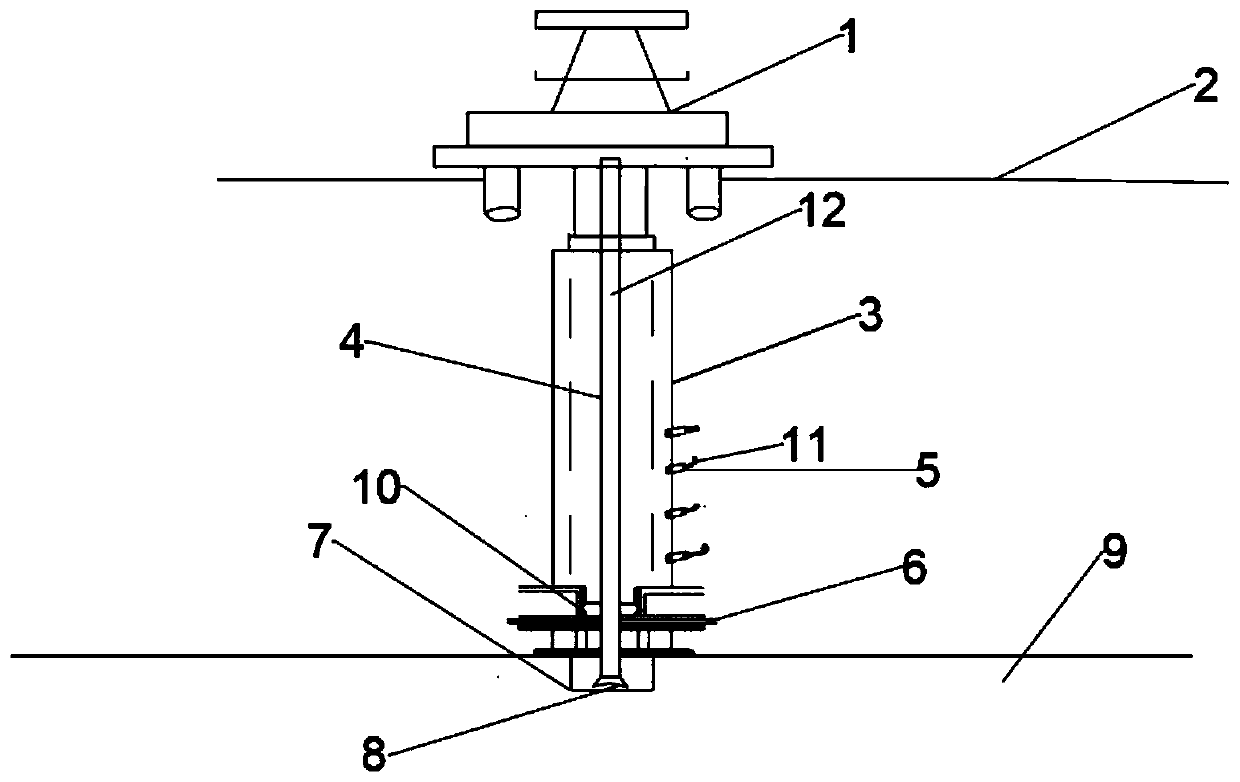

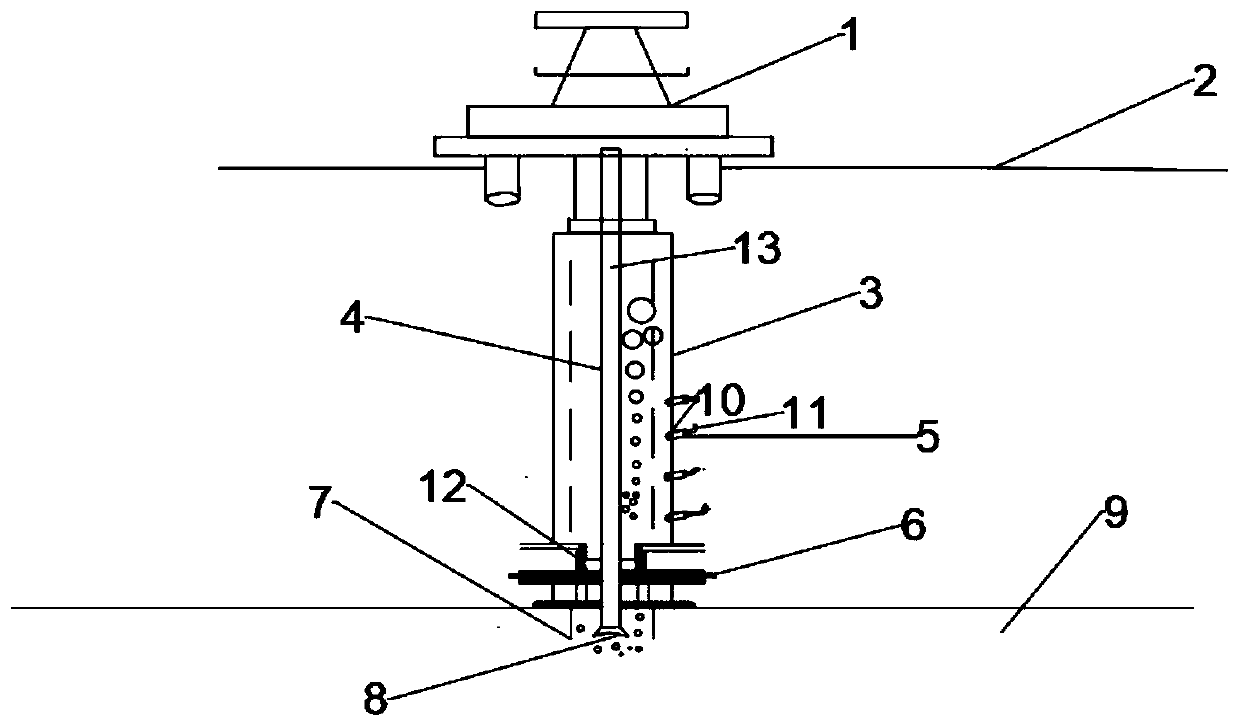

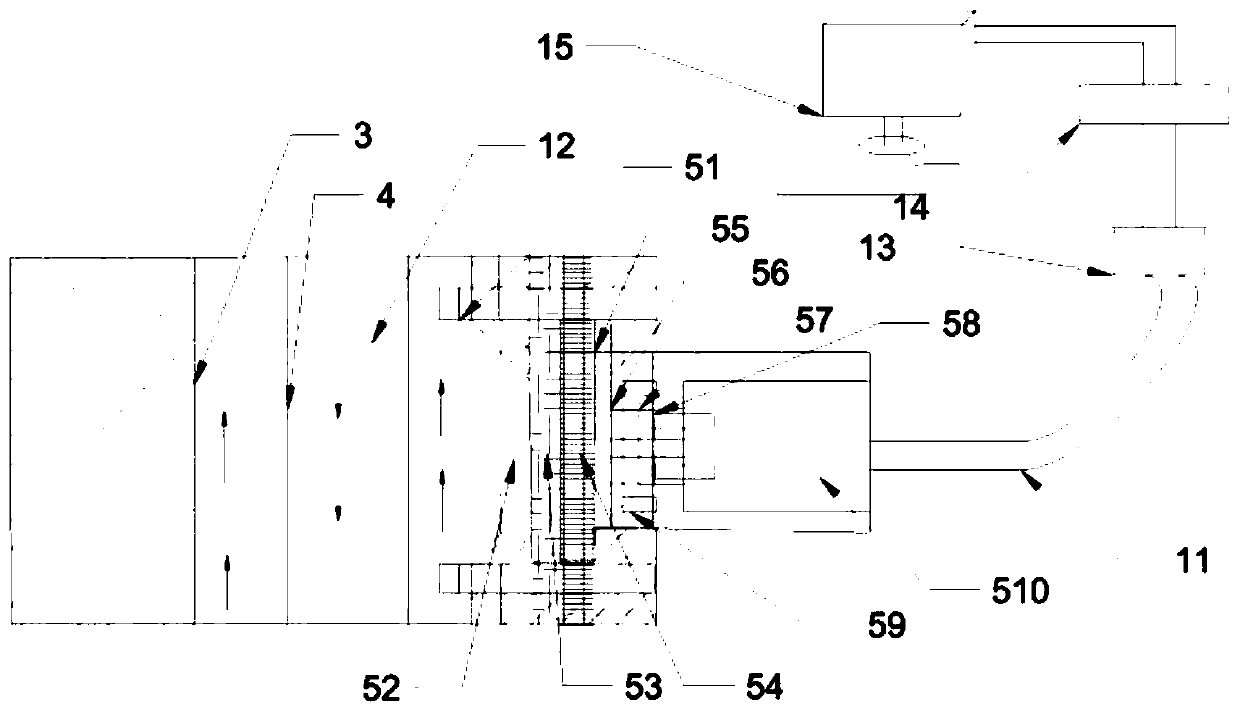

[0028] Such as Figure 1a , 1b , 2, the general layout diagram of the gas detection method device based on the whole semi-permeable membrane, the gas detection device 5 is arranged at a certain distance on the wall surface of the riser 3, the gas detection device 5 is connected with the data transmission cable 11, when the formation 9 overflows When the flowing gas invades, a large amount of gas is dissolved in the drilling fluid 12 in the riser 3, and the gas will be captured when the drilling fluid 12 flows through the gas detection device 5, and transmitted to the front-end signal processor 13 and signal amplifier 14 through the data transmission cable 11, and the signal All have reached a certain amplification, and at the same time, the stability of the transmission signal has been increased. Through the analysis and processing of the platform signal analysis device 15, the degree of air intrusion can be further judged, and corresponding guidance can be made for controlling...

Embodiment 2

[0037] Taking a 4,360-meter-deep well as an example, with a water depth of 1,260 m, the drilling fluid gas detection method in the riser is 41 minutes earlier than the pressure method to monitor the gas entering the riser, and 26 minutes earlier than the surface gas detection method. As shown in the table below:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com