Capacitor constant-power aging circuit and aging method

A capacitor and constant power technology, which is applied in the field of capacitor constant power sophisticated circuits, can solve problems such as electrolyte evaporation, capacitor withstand voltage rise, electrolytic paper carbonization, etc., to achieve the effects of prolonging service life, improving quality, and preventing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. It should be noted that the following description is only to help readers better understand this patent, so it only describes one or several specific implementations. The protection of this patent The scope is not limited to the following specific embodiments, but should include various changes made by those skilled in the art using conventional technical means.

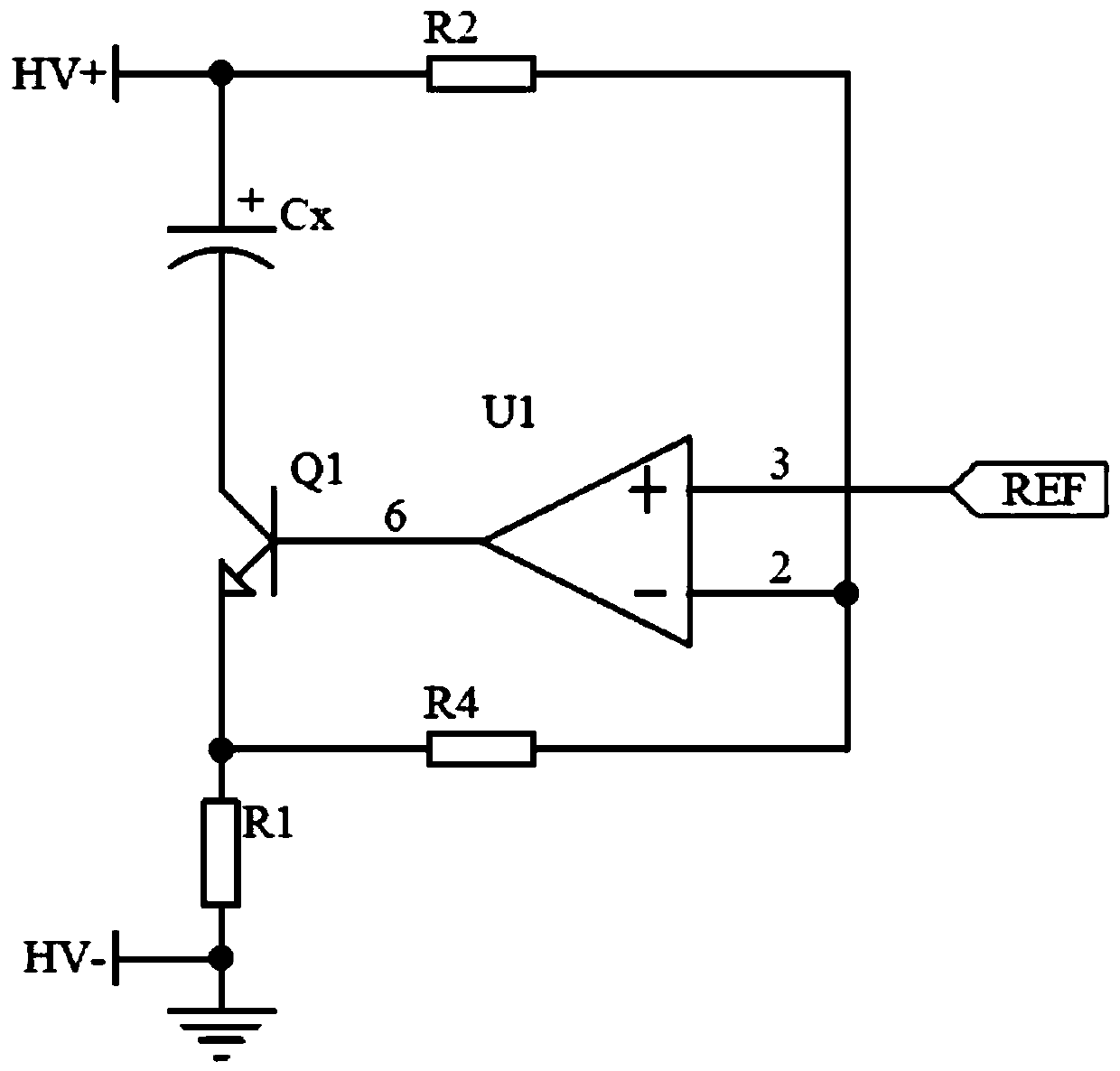

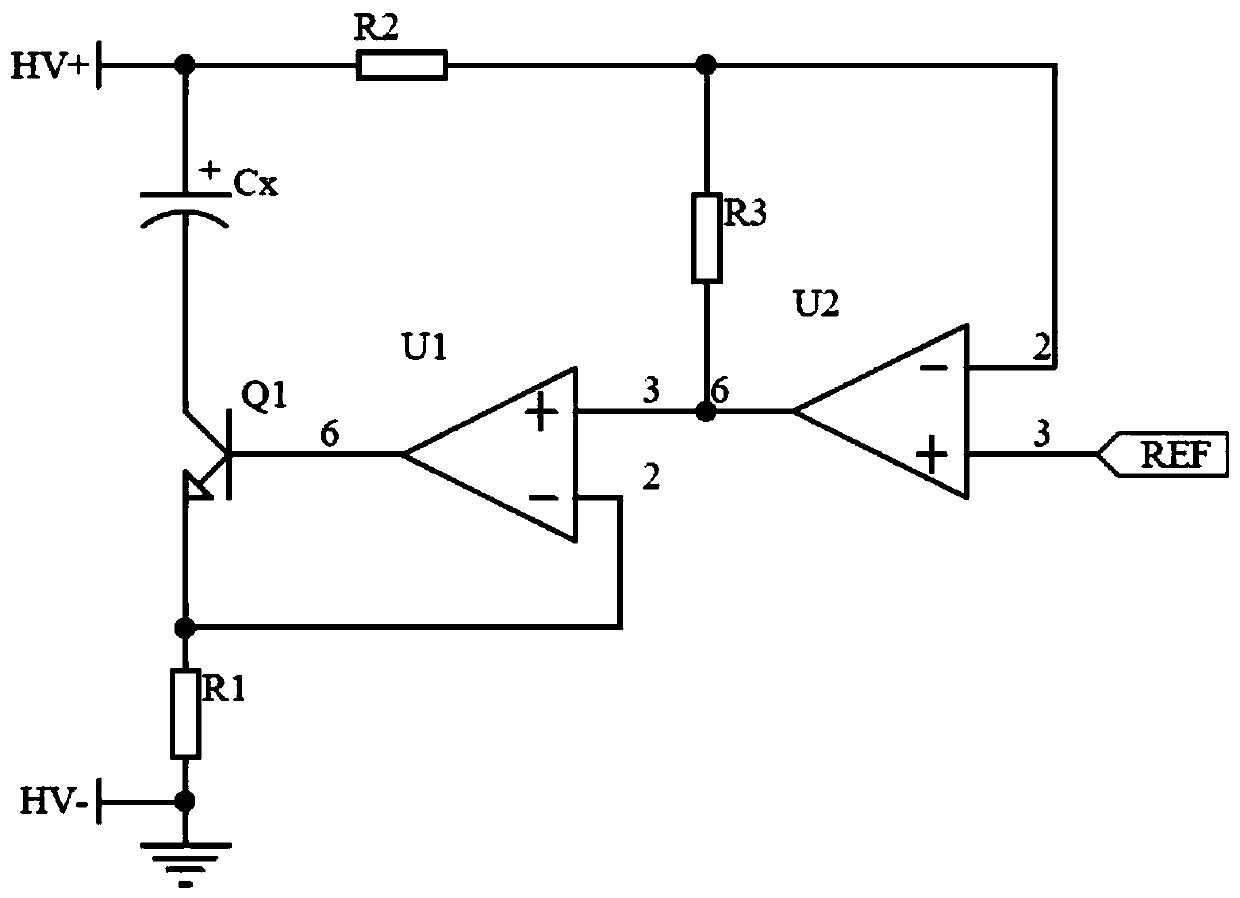

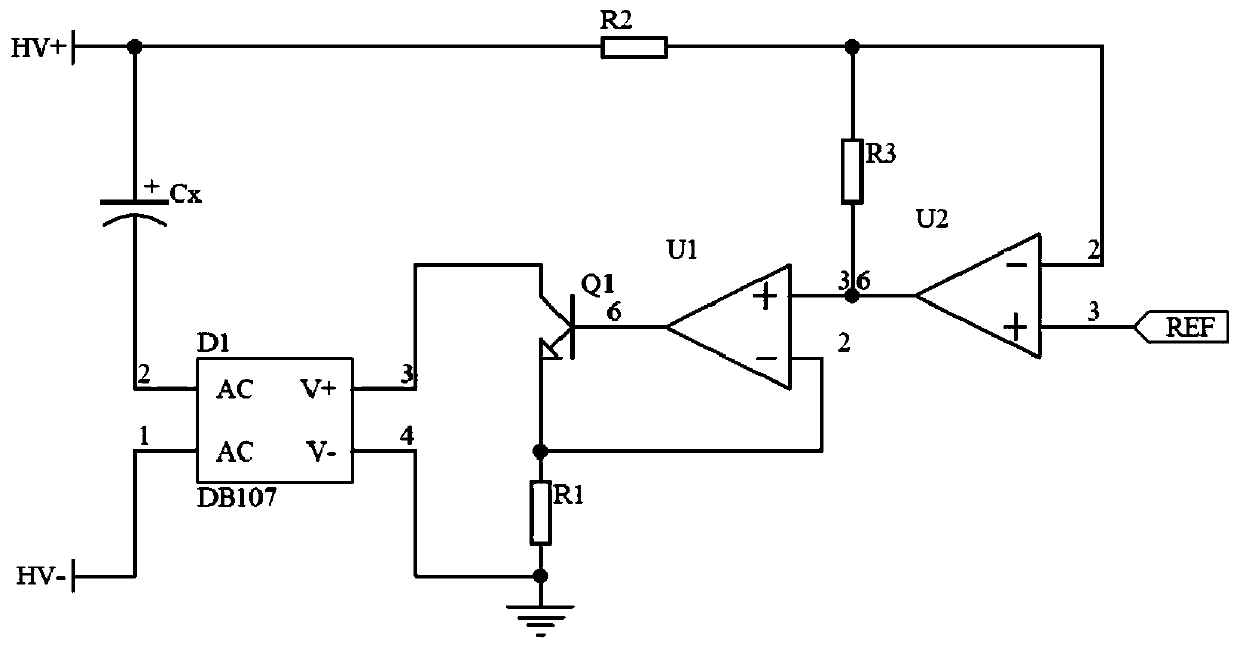

[0030] The invention provides a capacitor constant power aging circuit, which is used for the aluminum electrolytic capacitor constant power aging device, including the output terminal of the charging power supply, the capacitor Cx to be aged, the transistor Q1, and the operational amplifier U1, in addition to the forward input of the operational amplifier The terminal is connected with a reference voltage REF; the output terminal of the charging power supply forms a charging circuit with the cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com