Negative electrode lead paste suitable for high and low temperature environments, and preparation method thereof, and lead-acid storage battery

A negative lead paste, high and low temperature technology, used in lead-acid batteries, lead-acid battery construction, negative electrodes, etc., can solve problems such as never-occurring, battery life attenuation, etc., to alleviate deposition, improve stability, and improve electronic The effect of transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

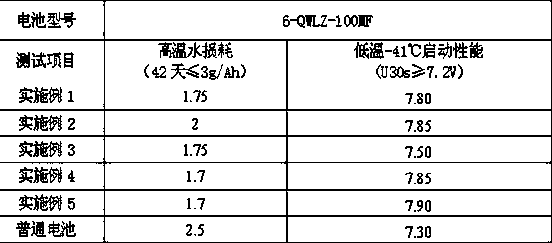

Examples

Embodiment 1

[0043] A lead-acid battery negative lead paste formulation suitable for both high temperature and low temperature environments, comprising the following ingredients in parts by weight:

[0044] Lead powder 100 parts,

[0045] 9.5 parts of dilute sulfuric acid,

[0046] Deionized water 8.5 parts,

[0047] 0.05 parts of high-strength staple fiber,

[0048] 0.15 parts of lignin,

[0049] Humic acid 0.5 parts,

[0050] Nano barium sulfate 0.75 part,

[0051] Granular carbon black 0.13 parts,

[0052] Surfactant 0.33 part,

[0053] 3.0 parts of carbon nanotube solution,

[0054] Hydrogen evolution inhibitor 0.18 parts.

[0055] Wherein, the massfraction of described dilute sulfuric acid is 48%. The high-strength short fibers are nanoscale polyester with a length of 3.5 mm and a diameter of 100 nm. The average particle size of the granular carbon black is 80nm.

[0056] The average size of the nano barium sulfate particles is 400nm. The mass % concentration of the carbon...

Embodiment 2

[0058] A lead-acid battery negative lead paste formulation suitable for both high temperature and low temperature environments, comprising the following ingredients in parts by weight:

[0059] 100 parts of lead powder,

[0060] 9.5 parts of dilute sulfuric acid,

[0061] Deionized water 8.5 parts,

[0062] 0.05 parts of high-strength staple fiber,

[0063] 0.15 parts of lignin,

[0064] Humic acid 0.5 part,

[0065] Nano barium sulfate 0.75 parts,

[0066] Granular carbon black 0.12 parts,

[0067] Surfactant 0.35 part,

[0068] 3.0 parts of carbon nanotube solution,

[0069] Hydrogen evolution inhibitor 0.12 parts.

[0070] Wherein, the mass fraction of the dilute sulfuric acid is 48%. The high-strength short fiber is nano-sized polyester with a length of 3mm and a diameter of 110nm. The average particle size of the granular carbon black is 90nm.

[0071] The average size of the nano barium sulfate particles is 400nm. The concentration mass % of the carbon nanotub...

Embodiment 3

[0073] A lead-acid battery negative lead paste formulation suitable for both high temperature and low temperature environments, comprising the following ingredients in parts by weight:

[0074] Lead powder 100 parts,

[0075] 9.5 parts of dilute sulfuric acid,

[0076] Deionized water 8.5 parts,

[0077] 0.05 parts of high-strength staple fiber,

[0078] 0.10 parts of lignin,

[0079] Humic acid 0.5 part,

[0080] Nano barium sulfate 0.75 parts,

[0081] Granular carbon black 0.12 parts,

[0082] Surfactant 0.32 parts,

[0083] 2.0 parts of carbon nanotube solution,

[0084] Hydrogen evolution inhibitor 0.18 parts.

[0085] Wherein, the concentration of described dilute sulfuric acid is 47%. The high-strength short fiber is nano-scale polyester with a length of 3.5mm and a diameter of 100nm. The average size of the granular carbon black particles is 100nm, and the average size of the nano barium sulfate particles is 450nm. The concentration mass % of the carbon nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com