Chocolate for frozen drinks and preparation method thereof

A technology for frozen drinks and chocolate, applied in the application, frozen desserts, cocoa and other directions, can solve the problems of difficult to keep smooth chocolate, thin chocolate, low gram weight, high calorie, etc., achieve rich nutrition and health care effect, shorten preparation Process time and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

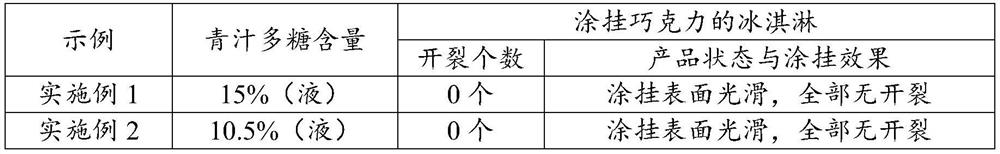

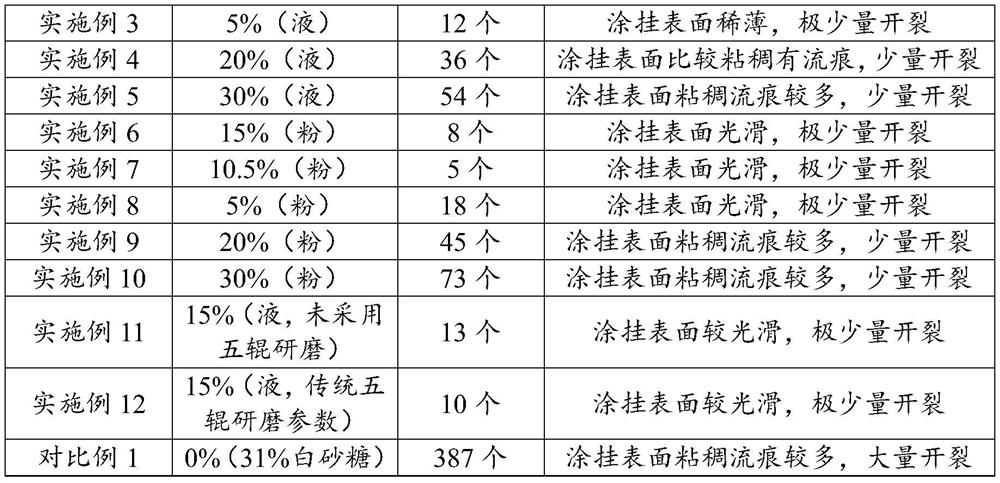

Examples

preparation example Construction

[0042] The preparation method of above-mentioned chocolate, comprises the steps:

[0043] S1, mix the green juice polysaccharide powder, white granulated sugar and palm oil according to the ratio, use a two-roller grinder for rough grinding, and then use a five-roller grinder for fine grinding to obtain a green juice polysaccharide concentrate, wherein the process of the five-roller grinder The parameters are: pressure 72MPa, temperature 30°C-35°C for the first roll and the second roll, 40°C-55°C for the third roll and the fourth roll, 30°C-35°C for the fifth roll, fine grinding time 4-6 hours , the fineness of the obtained green juice polysaccharide concentrate is less than 22 microns, and the temperature is about 30°C-35°C;

[0044] S2, separately weigh white granulated sugar, whole milk powder, skimmed milk powder, whey powder, coconut oil and palm oil according to the mass percentage, mix them, and finely grind them at 45°C for 5-8 hours in a fine grinding tank. After the...

Embodiment 1

[0046] The present embodiment adopts following method to prepare green juice polysaccharide chocolate:

[0047] S1, taking the total mass of the green juice polysaccharide concentrate as 100%, get 30% green juice polysaccharide powder (the mixture of green juice powder and jujube polysaccharide powder with a mass ratio of 1:1), 30% white granulated sugar powder and 40% After the palm oil is mixed, first put it into a two-roller grinder for rough grinding at 45°C for 1 hour, and then use a five-roller grinder for fine grinding, wherein the process parameters of the five-roller grinder are: pressure 72MPa, temperature 32 ℃, the second roll is 35°C, the third roll is 42°C, the fourth roll is 55°C, the fifth roll is 32°C, the whole grinding time is about 5 hours, and the green juice with a fineness of about 20 microns and a temperature of about 32°C is obtained polysaccharide concentrate;

[0048] S2, taking the total mass of chocolate as 100%, weigh 1% white granulated sugar, 10...

Embodiment 2

[0051] The present embodiment adopts following method to prepare green juice polysaccharide chocolate:

[0052] S1, taking the total mass of the green juice polysaccharide concentrate as 100%, get 30% green juice polysaccharide powder (the mixture of green juice powder and jujube polysaccharide powder with a mass ratio of 1:1), 30% white granulated sugar powder and 40% After the palm oil is mixed, first put it into a two-roller grinder for rough grinding at 45°C for 1 hour, and then use a five-roller grinder for fine grinding, wherein the process parameters of the five-roller grinder are: pressure 72MPa, temperature 32 ℃, the second roll is 35°C, the third roll is 42°C, the fourth roll is 55°C, the fifth roll is 32°C, the whole grinding time is about 5 hours, and the fineness is about 20 microns, and the temperature is about 32°C. juice polysaccharide concentrate;

[0053] S2, taking the total mass of chocolate as 100%, weigh 4% white granulated sugar, 14% whole milk powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com