Outer wall cleaning equipment for cleaning building outer wall

A technology for exterior wall cleaning and building exterior walls, applied in cleaning equipment, construction, building maintenance, etc., can solve the problems of high manufacturing and use costs, general cleaning strength, and complex overall structure, and achieve low manufacturing and use costs, The effect of fast cleaning speed and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

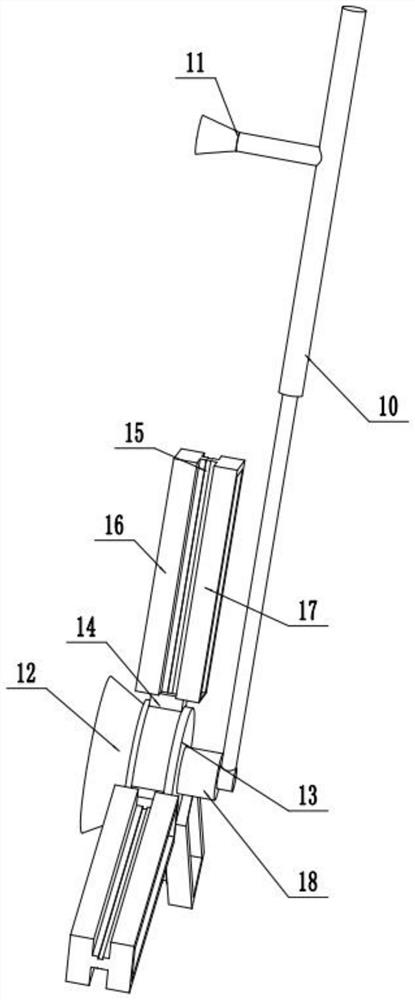

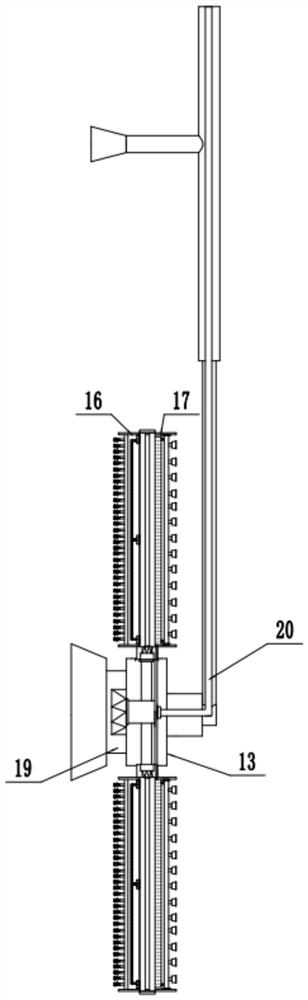

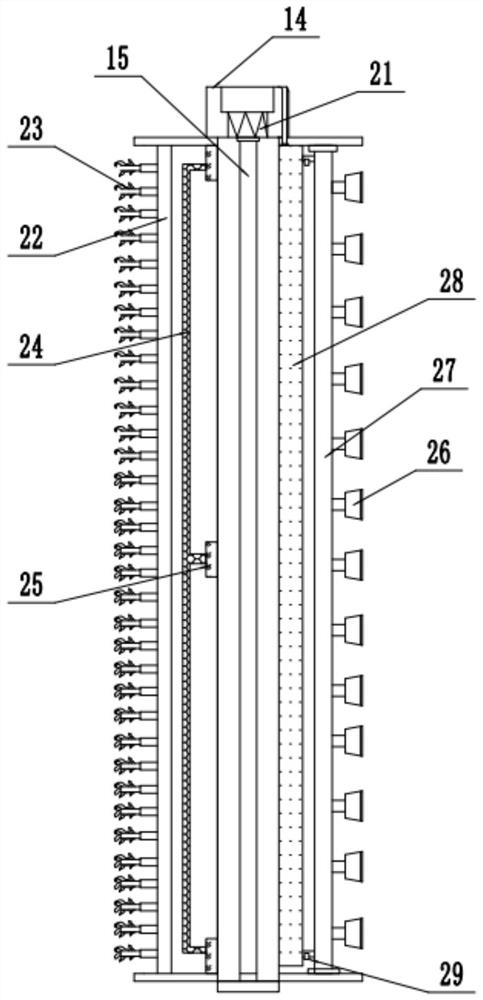

[0023] see Figure 1-4 , an exterior wall cleaning device for cleaning exterior walls of buildings, comprising a lifting rod 10, a mounting base 13, a dust removal tank 16, and a cleaning tank 17; the inside of the mounting base 13 is set as a cavity structure, and the outside A vertical lifting rod 10 is fixedly installed on the side through a connecting rod 18, and the top of the lifting rod 10 is connected upward with a lifting device fixed on the roof, a left and right moving device and a front and rear moving device, and the displacement of the lifting rod 10 is controlled by front, rear, left, right, up and down. , so as to control the position of cleaning the outer wall. A set of main suction cups 12 is fixedly installed on the inner surface of the mounting base 13, and the mounting base 13 can be fixed by adsorbing the main suction cups 12 on the outer wall, thereby facilitating stable cleaning of the outer wall. A set of first servo motors 30 is fixed inside the conn...

Embodiment 2

[0027]On the basis of Embodiment 1, a group of auxiliary suction cups 11 smaller than the main suction cup 12 are fixedly installed on the left side wall of the middle part of the lifting rod 10 to the left. Whether the rod 10 needs to be used or not can be judged by itself based on the stability of the rod 10 in use, and it mainly plays an auxiliary fixing role when the elevating rod 10 and the mounting seat 13 are unstable. The first servo motor 30, the second rotating motor 21, the booster pump 29, and the fan 25 are all electrically connected to the control cabinet fixed on the roof, and the operator controls the operation of each component remotely.

[0028] The working principle of the present invention is: first, according to the position of the outer wall to be cleaned, the installation seat 13 is adjusted to the position to be cleaned by various mobile devices arranged on the roof, and then the opening side of the dust removal tank 16 faces outward wall, so that the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com