Novel liquid collector device

A liquid collector, a new type of technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of deviations in the design values of the external dimensions of parts, affecting the normal operation of the desulfurization system, and restricting the quality of production and installation. Achieve the effect of good applicability, good smoke removal effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

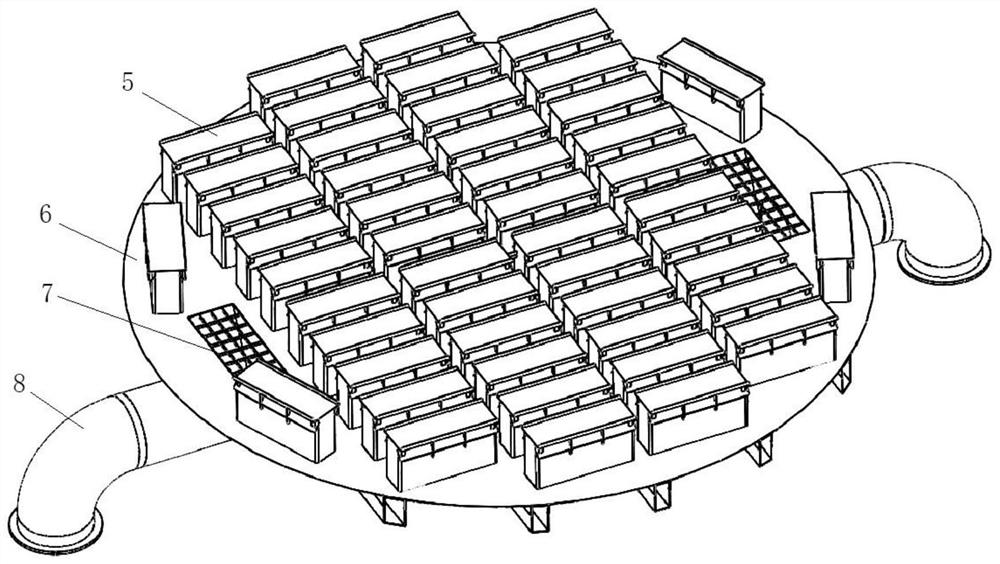

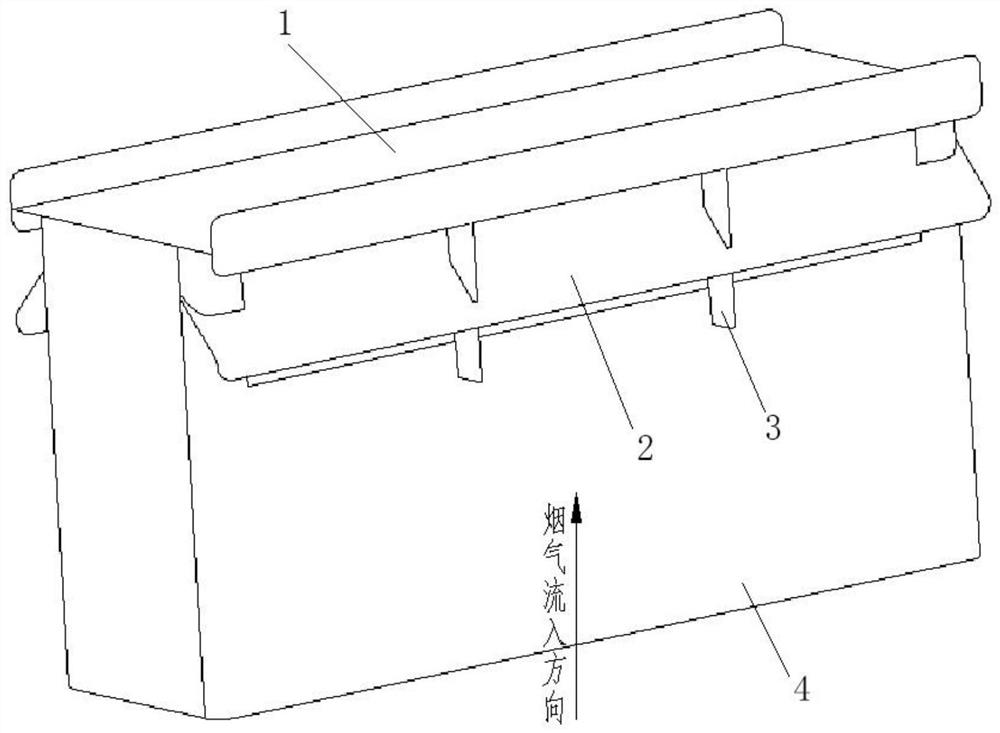

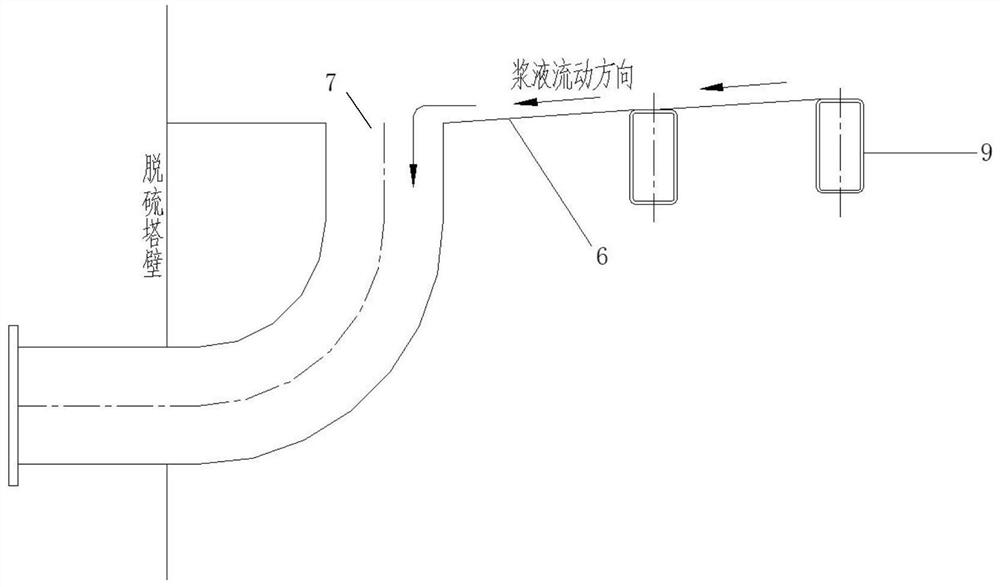

[0034] An alloy steel plate with a high middle and low sides is set below the circulating spray layer as the liquid collecting pan 6, and the rising air cap 5 is welded on the upper part of the liquid collecting pan 6, and the outer walls of every two rising air caps 5 are connected to each other to form a lateral support; The liquid discharge port 7 is arranged on both sides of the liquid collection tray 6, and the cross section of the liquid discharge port 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com