Garbage collection system with vacuumizing packaging function and control method thereof

A garbage collection and vacuuming technology, applied in garbage collection, garbage conveyance, packaging and other directions, can solve the problems of high price of broken blades, difficult to popularize and apply, and spread of germs to the outside. The effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

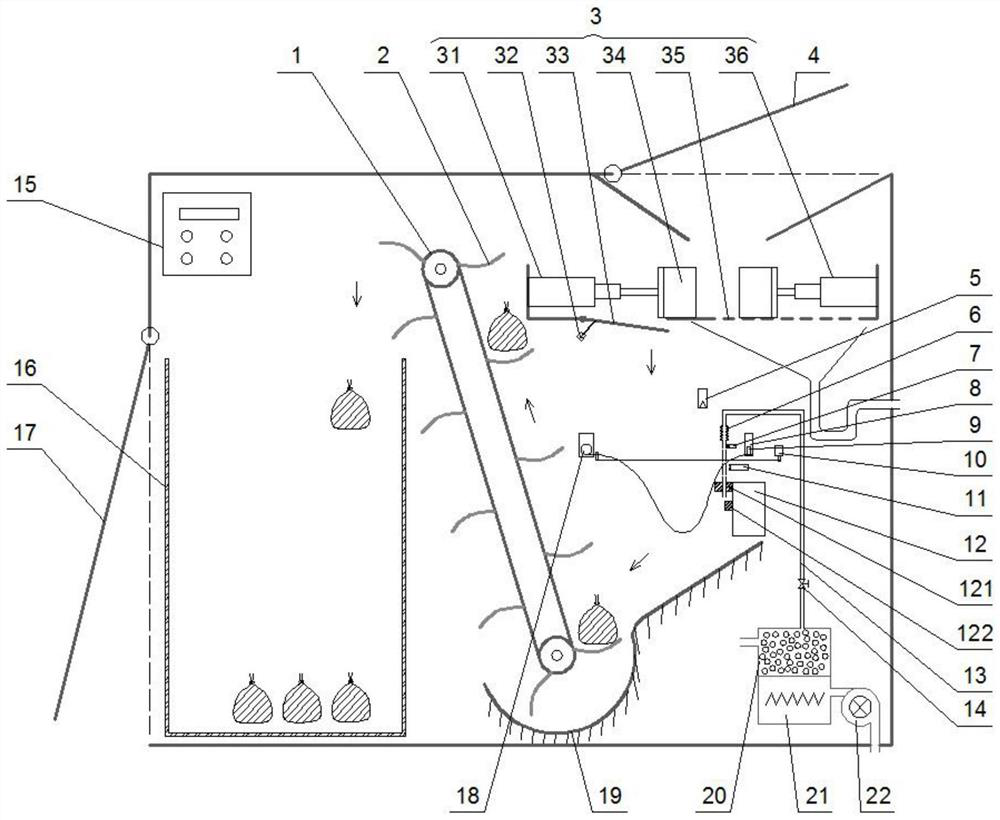

[0042] A garbage collection system with the function of vacuuming and packing.

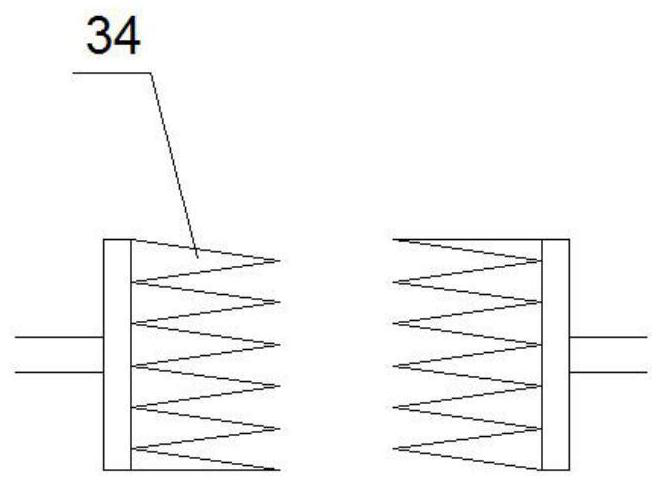

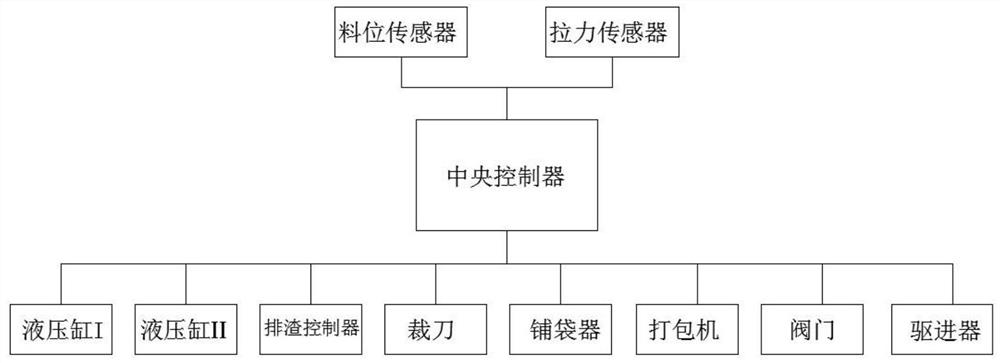

[0043] refer to Figure 1~3 , the garbage collection system includes a barrel cover 4 and a central controller 15 arranged on its top, and a filter press 3 is arranged below the barrel cover 4 . The filter press 3 includes a hydraulic cylinder I31, a hydraulic cylinder II36, a toothed extrusion head 34, a slag discharge door 33 and a filter screen 35; the toothed extrusion head 34 is provided with at least one pair of toothed extrusion heads arranged in pairs 34 are installed facing each other, the teeth are staggered, and are respectively connected to the hydraulic cylinder I31 and the hydraulic cylinder II36. The lower end of the filter press 3 is provided with a slag discharge door 33 and a filter screen 35, and the slag discharge door 33 is connected to a slag discharge controller 32 .

[0044]A liquid receiving tank is arranged below the filter screen 35, and the liquid receiving tank leads...

Embodiment 2

[0058] The control method of this embodiment is applied to the garbage collection system with vacuum packing function described in Embodiment 1, which includes the following steps:

[0059] Step 1, compress the garbage and transfer it to garbage bags;

[0060] Step 2, closing the garbage bag;

[0061] Step 3, extend the exhaust pipe 13 into the garbage bag, tie the garbage bag for the first time, and ensure that the exhaust pipe 13 is inserted into the garbage bag when tying the mouth;

[0062] Step 4, vacuumize the garbage bag through the exhaust pipe 13;

[0063] Step 5, tie the garbage bag for the second time, and the exhaust pipe 13 is not tied into the garbage bag during the tie;

[0064] Step 6, lifting and conveying the vacuumized garbage bag into the garbage bin 16 for storage and waiting for transfer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com