Automatic loading and unloading system for tin spraying procedure for PCBs

A technology for automatic loading and unloading of PCB boards, applied in spraying devices, devices for coating liquid on the surface, conveyors, etc., can solve the problems of lower production efficiency, inability to adapt to PCB board production, and small adjustable range, etc., to achieve The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

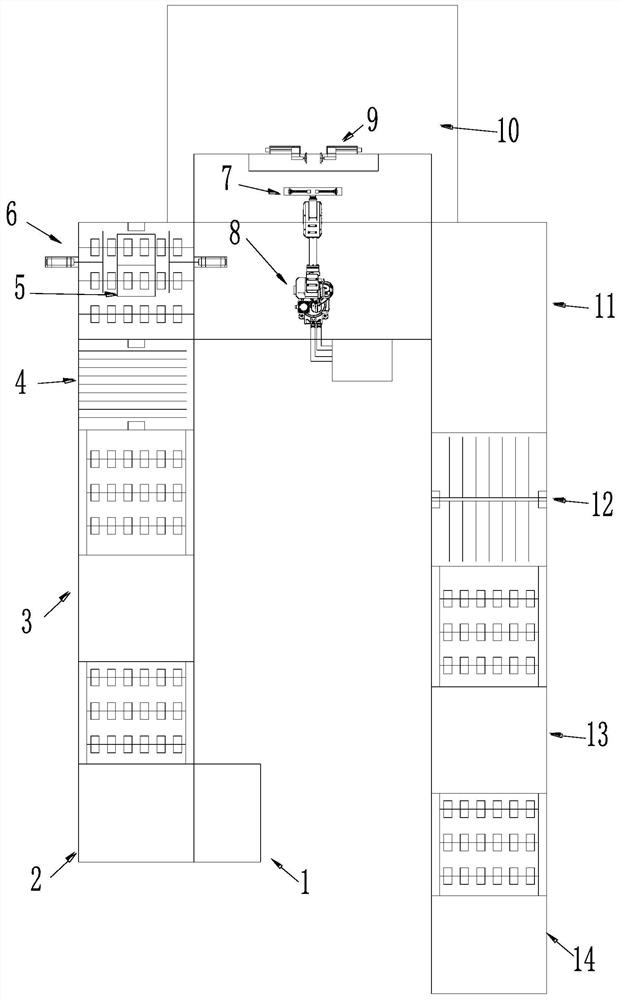

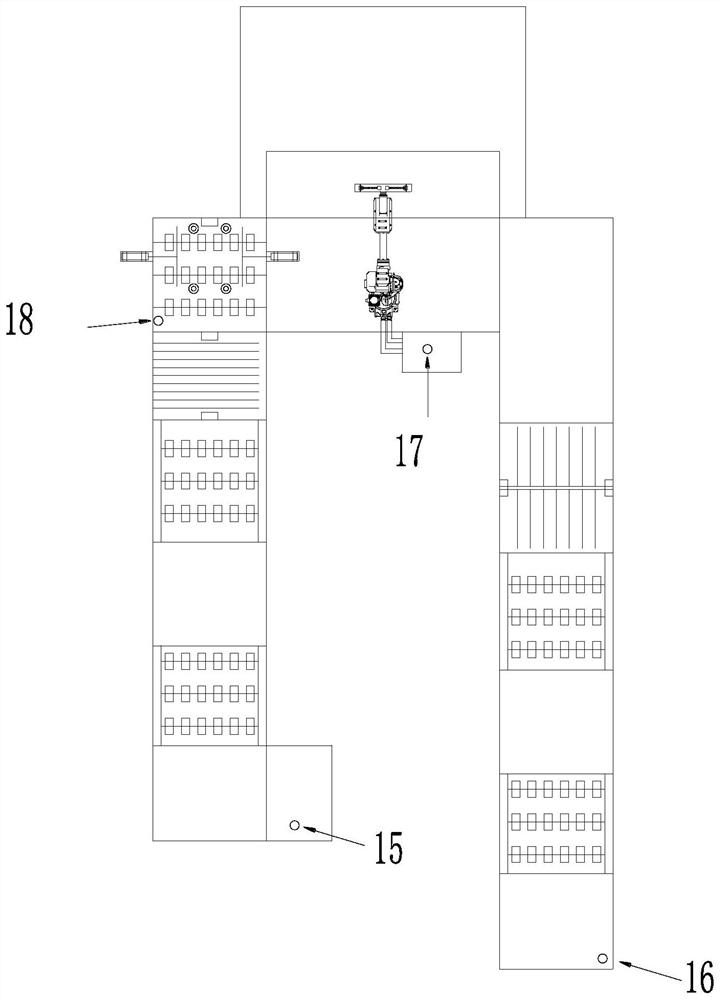

[0031] Such as figure 1 Shown is an automatic loading and unloading system for PCB board tin spraying process of the present invention. Including the main console 1, automatic board placement machine 2, spray tin pretreatment section 3, temporary storage machine 4, top board device 5, positioning device 6, mechanical arm adjustable fixture 7, mechanical arm 8, and spray tin machine adjustable slide Channel device 9, tin spraying machine 10, air floating bed 11, solar panel turning machine 12, tin spraying post-processing section 13, automatic board collecting machine 14. The entire production line is arranged in a "U" shape, in which the main console 1, the automatic board placement machine 2, the pre-treatment section 3, the temporary storage machine 4, the top plate device 5, and the positioning device 6 are arranged in a straight lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com