Low-pressure lng gas supply system for dual-fuel marine engines and dual-fuel ships

An air supply system and engine technology, applied in the field of ships, can solve the problems of many maintenance work, large ship energy consumption, large workload, etc., and achieve the effects of low maintenance workload, low trouble repair difficulty, and easy maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

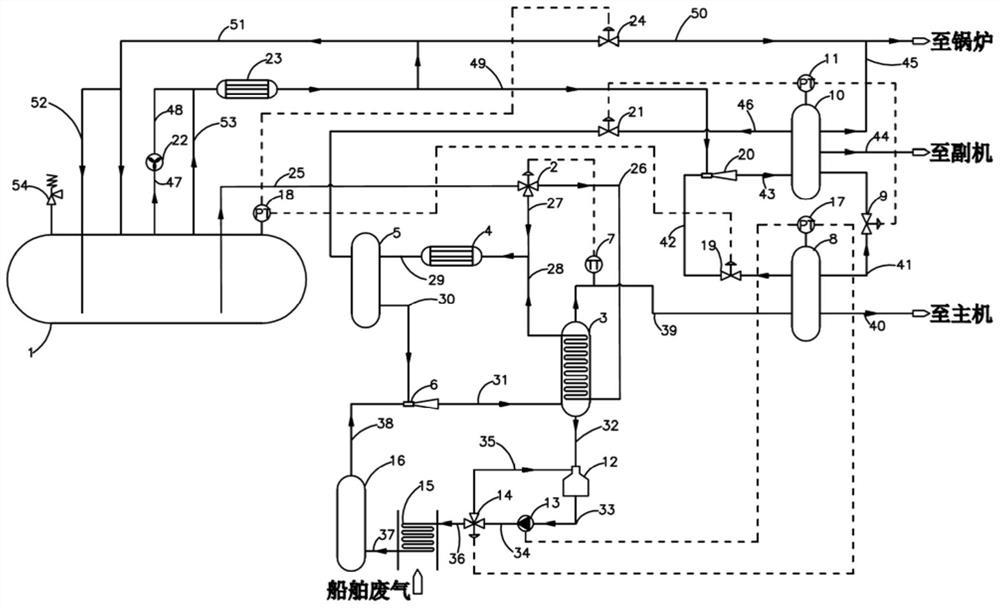

[0032] Such as figure 1 As shown, the dual-fuel marine engine low-pressure LNG gas supply system provided by the first embodiment of the present invention includes an LNG storage tank 1, a first three-way regulating valve 2, a gas mixture separator 3, a gasifier 4, a mixing tank 5, High-pressure injection pump 6, high-pressure buffer tank 8, first regulating valve 9, low-pressure buffer tank 10, liquid collection tank 12, working medium pump 13, second three-way regulating valve 14, exhaust gas heat exchanger 15, gas-liquid separator 16 , the second regulating valve 19, the low-pressure jet pump 20, the third regulating valve 21, the exhaust fan 22, the heater 23 and the fourth regulating valve 24.

[0033] Specifically, the bottom of the LNG storage tank 1 communicates with the inlet of the first three-way regulating valve 2, and one outlet of the first three-way regulating valve 2 communicates with the inlet of the internal pipeline of the gas mixture separator 3, and the fi...

no. 2 example

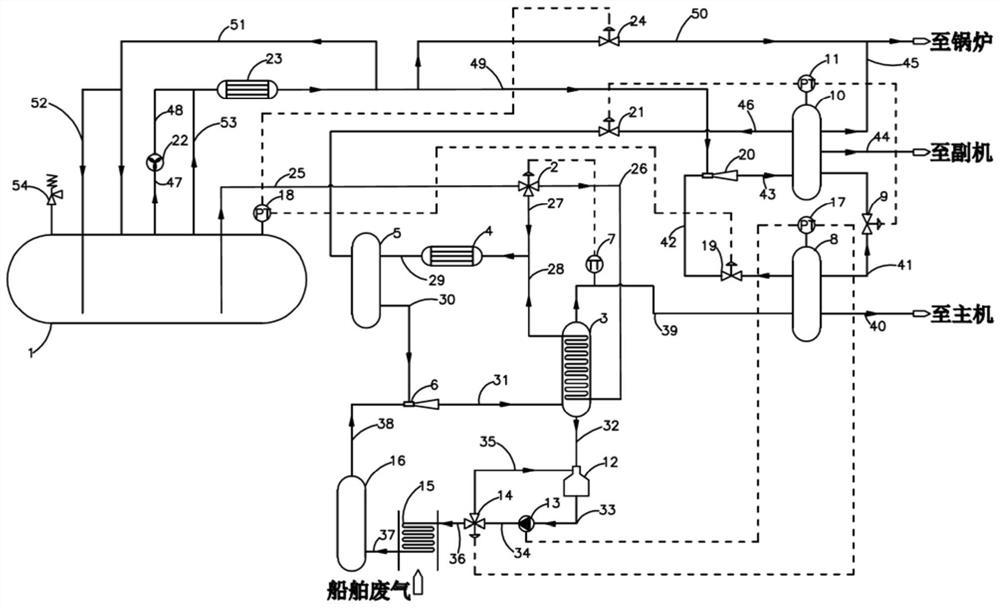

[0091] Such as figure 2 As shown, the dual-fuel marine engine low-pressure LNG gas supply system provided by the second embodiment of the present invention has roughly the same structure as that of the first embodiment, except that the position of the outlet of the twenty-seventh pipeline 51 connected to the heater 23 is different. .

[0092] Specifically, one end of the twenty-seventh pipeline 51 communicates with the top of the LNG storage tank 1, and the other end is first collected to the twenty-fifth pipeline 49, and then connected to the heater 23 through the twenty-fifth pipeline 49. The exit is connected.

[0093] The present invention utilizes ship waste gas as an energy source, jet pump 6 / 20 and exhaust fan 22 as a power source, realizes LNG gas supply function and boil-off gas treatment function, and cancels the low-temperature submersible pump and Equipment with high investment cost and difficult maintenance such as compressors reduces the investment and operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com