Biodegradable injectable filler, its preparation method and its application

A biodegradable and filling technology, applied in drug delivery, pharmaceutical formulations, prostheses, etc., can solve problems such as uneven particle size distribution of PLLA, affect injection effectiveness and safety, increase injection stimulation and adverse reactions, etc., to improve Adhesion ability and residence time, natural cosmetic effect, effect of improving cell affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0167] Example 1 Preparation of PLLA polymer

[0168] Add 500g of L-lactide to a 2000mL single-necked bottle, and heat it to 130°C under nitrogen protection. After the L-lactide is completely melted, add 0.15g of stannous isooctanoate and 1.5g of lauryl alcohol, and keep warm at 130°C React for 24 hours, after cooling the reaction solution to room temperature, add 1L of dichloromethane, stir to dissolve, filter, transfer the resulting solution to a 50L reaction kettle, add 4L of dichloromethane, dropwise add 25L of methanol, crystallize at room temperature, filter, The filter cake was dried at 50°C to obtain PLLA polymer with a weight average molecular weight of 36,000.

Embodiment 2

[0169] Example 2 Preparation of PLLA polymer

[0170] Add 500g of L-lactide to a 2000mL single-necked bottle, and heat it to 120°C under nitrogen protection. After the L-lactide is completely melted, add 0.1g of stannous chloride and 1.2g of lauryl alcohol, and keep the reaction at 120°C. After 48 hours, after the reaction solution was lowered to room temperature, 1 L of chloroform was added, stirred to dissolve, filtered, the solution was transferred to a 50 L reaction kettle, 4 L of chloroform was added, 25 L of n-heptane was added dropwise, crystallized at room temperature, filtered, The filter cake was dried at 50°C to obtain PLLA polymer with a weight average molecular weight of 39,000.

Embodiment 3

[0171] Example 3 Preparation of PLLA polymer microparticles

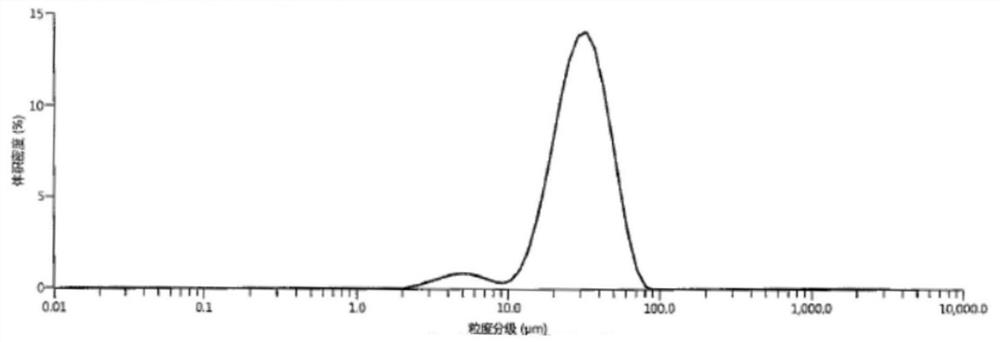

[0172] Weigh 200 g of the PLLA polymer prepared in Example 1, add 4 L of tetrahydrofuran, stir to dissolve, slowly add 12 L of anhydrous methanol dropwise, after the dropwise addition, stir for about 1 hour, filter, and rinse the filter cake with anhydrous methanol, Vacuum-dried at 35°C and passed through a 200-mesh sieve to obtain PLLA particles with a heat of fusion of 54.3J / g, D(3,2) of 21.7μm, D(4,3) of 32.4μm, and a maximum particle size of about 66.9 μm, see the attached particle size distribution figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap