Rear axle steering hydraulic cylinder assembly and steering system

一种转向液压、后桥的技术,应用在转向机构、转向拉杆、机械转向器等方向,能够解决随动转向桥响应特征与抗冲击能力影响车辆操纵稳定性、安全性、复杂应用环境、工况复杂等问题,达到阀组结构布局合理、系统安全可靠、压力损失小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0078] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

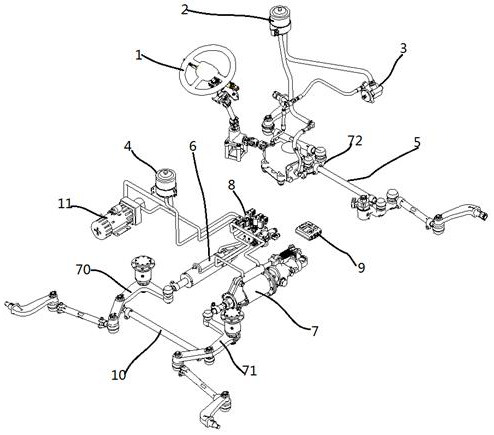

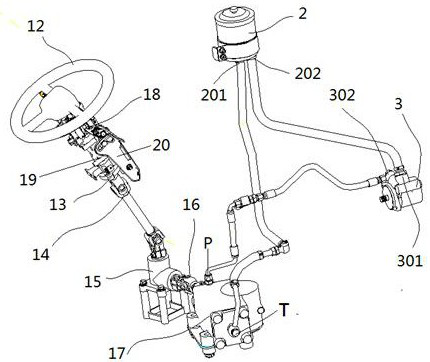

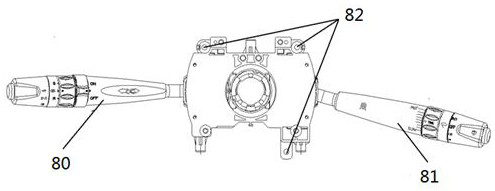

[0079] In order to solve the problems in the prior art, the present invention provides a high-reliability electromechanical hydraulic all-wheel steering system and its rear axle self-aligning and locking device, especially a 4X4 electromechanical hydraulic all-wheel steering system. The all-wheel steering device of the system adopts hydraulic power-assisted mechanical steering on the front axle, and the rear axle uses an electronically controlled hydraulic cylinder to drive the steering of the rear axle. As a preference, the high-reliability 4X4 electromechanical-hydraulic all-wheel steering system and its rear axle passive self-aligning and locking device are suitable for wheeled vehicles of mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com