Mulberry wine brewing technology

A mulberry wine and process technology, applied in the field of winemaking, can solve the problems affecting the sensory degree of mulberry wine, poor flavor of mulberry wine, difficult process control, etc., and achieve the effects of avoiding bacterial mold infection, long aftertaste and good sensory degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

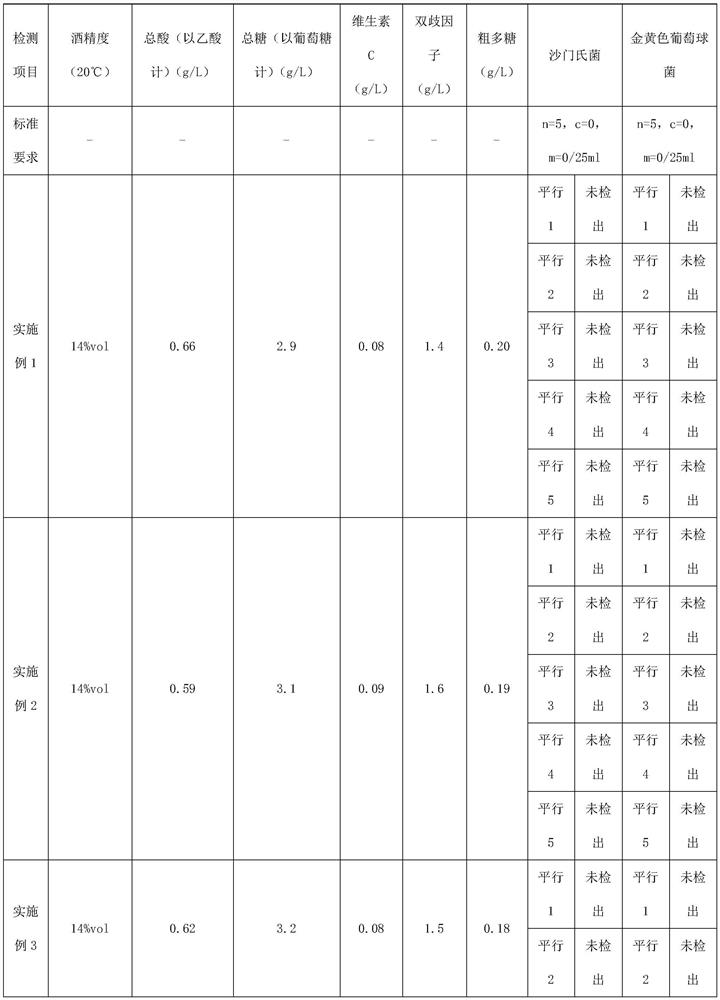

Embodiment 1

[0043] A kind of mulberry wine brewing process, comprises the steps:

[0044] (1) Low-temperature treatment: Place fresh mulberries in a cold storage for cooling treatment. The storage temperature is 8-10°C. Before storage, the mulberries are cleaned and selected to remove injuries, dry scars, abnormal colors, mildew or damage. Mulberries infested by diseases and insect pests;

[0045] (2) Fruit crushing: crush the mulberries after low temperature treatment to obtain fruit pulp, add potassium metabisulfite and stir evenly during the crushing process or after the crushing is completed, and add 0.1g coke per 1L of fruit pulp when adding potassium sulfite Potassium sulfite is added according to the ratio of potassium pyrosulfite, among which, potassium metabisulfite needs to be dissolved in pure water 10 times that of potassium metabisulfite, and then slowly added to the fruit pulp and stirred evenly;

[0046] (3) Adjustment of ingredients: adjust the sugar content and alcohol c...

Embodiment 2

[0055] A kind of mulberry wine brewing process, comprises the steps:

[0056] (1) Low-temperature treatment: Place fresh mulberries in a cold storage for cooling treatment. The storage temperature is 8-10°C. Before storage, the mulberries are cleaned and selected to remove injuries, dry scars, abnormal colors, mildew or damage. Mulberries infested by diseases and insect pests;

[0057] (2) Fruit crushing: crush the mulberries after low temperature treatment to obtain fruit pulp, add potassium metabisulfite and stir evenly during the crushing process or after the crushing is completed, and add 0.1g coke per 1L of fruit pulp when adding potassium sulfite Potassium sulfite is added according to the ratio of potassium pyrosulfite, among which, potassium metabisulfite needs to be dissolved in pure water 10 times that of potassium metabisulfite, and then slowly added to the fruit pulp and stirred evenly;

[0058] (3) Composition adjustment: adjust the sugar content and alcohol cont...

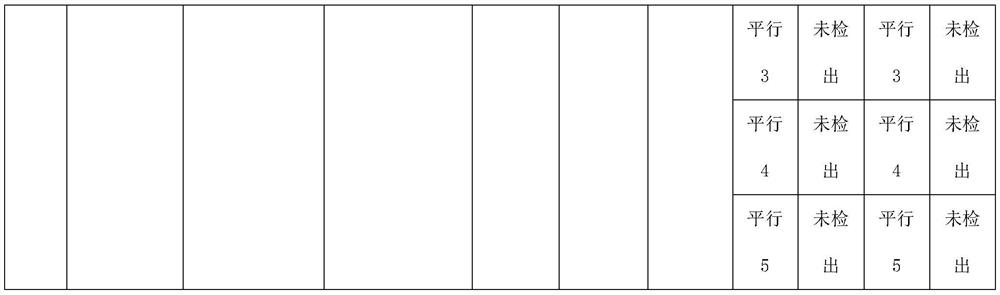

Embodiment 3

[0067] A kind of mulberry wine brewing process, comprises the steps:

[0068] (1) Low-temperature treatment: Place fresh mulberries in a cold storage for cooling treatment. The storage temperature is 8-10°C. Before storage, the mulberries are cleaned and selected to remove injuries, dry scars, abnormal colors, mildew or damage. Mulberries infested by diseases and insect pests;

[0069] (2) Fruit crushing: crush the mulberries after low temperature treatment to obtain fruit pulp, add potassium metabisulfite and stir evenly during the crushing process or after the crushing is completed, and add 0.1g coke per 1L of fruit pulp when adding potassium sulfite Potassium sulfite is added according to the ratio of potassium pyrosulfite, among which, potassium metabisulfite needs to be dissolved in pure water 10 times that of potassium metabisulfite, and then slowly added to the fruit pulp and stirred evenly;

[0070] (3) Composition adjustment: adjust the sugar content and alcohol cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com