Hygroscopic polyester fiber and preparation method thereof

A polyester fiber and polyurethane fiber technology, applied in the field of synthetic fibers, can solve the problems of poor hygroscopicity and achieve the effect of improving hygroscopicity and improving surface smoothness

Active Publication Date: 2020-09-04

胜利油田兴达高祥新材料有限责任公司

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]

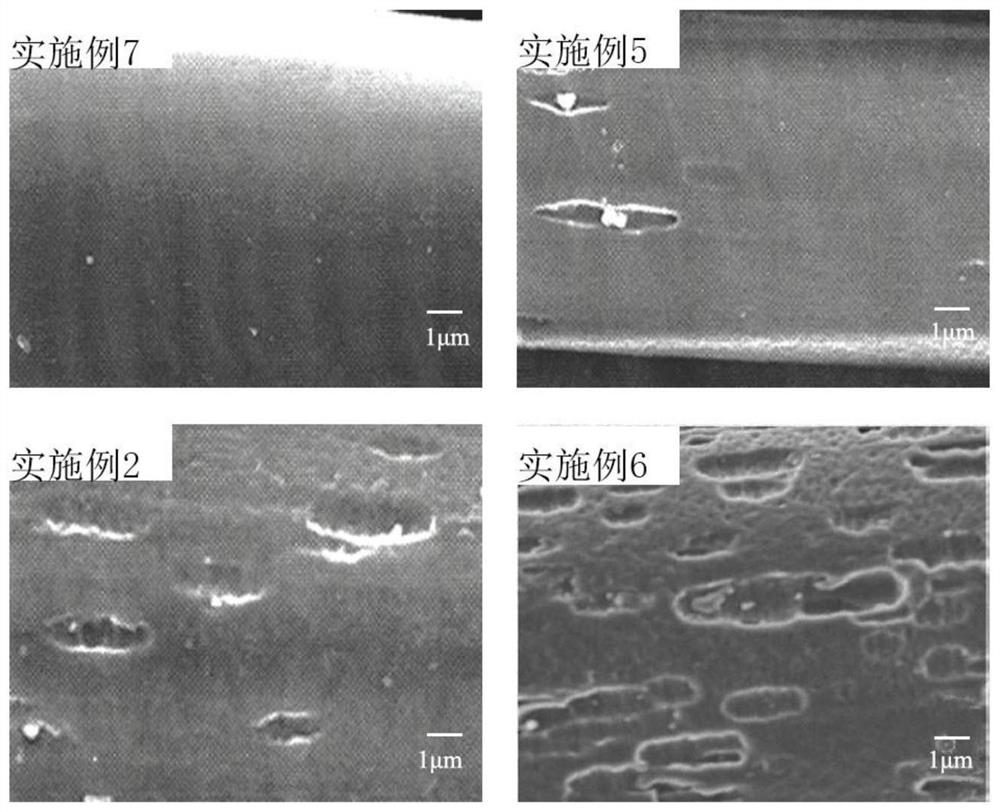

According to the principle of capillary water absorption, the present invention provides a new method for preparing polyester fiber filaments with a large number of pores on the surface and inside. The fiber uses a mixed solution of polyester and chitosan as a spinning solution, and is spun by a dry method. Prepared by enzymatically decomposing chitosan, it can further improve the hygroscopicity of the existing special-shaped yarn, and greatly improve the defects of smooth fiber surface and poor hygroscopicity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but the examples do not limit the present invention in any form. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in the technical field.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a hygroscopic polyester fiber and a preparation method thereof. The preparation method comprises the following steps: 1) preparing polyester through substitution reaction of terephthaloyl chloride and ethylene glycol, and mixing and dissolving the polyester with chitosan to obtain a spinning solution; 2) performing dry spinning; and 3) hydrolyzing chitosan blended in fiberfilaments by using cellulase and N-acetylglucosaminidase to obtain the fiber filaments with a large number of pore channels in the surfaces and the interiors. The defects of smooth surface and poor hygroscopicity of a PET fiber are overcome.

Description

technical field [0001] The invention belongs to the field of synthetic fibers, and in particular relates to a hygroscopic polyester fiber and a preparation method thereof. Background technique [0002] As the largest synthetic fiber, polyester is polyethylene terephthalate, or PET for short, which is formed by esterification polymerization of ethylene glycol and terephthalic acid. Polyester has many excellent properties, such as excellent stretchability and shrinkage resistance, high elastic modulus and breaking strength, good resilience, good thermoplasticity, heat and light resistance, stable size, and low price, so it is widely used in clothing industry. However, polyester has disadvantages such as poor dyeability, poor hygroscopicity, and smooth surface. Therefore, in order to improve the shortcomings of polyester, it is necessary to modify polyester. [0003] Carrying out hygroscopicity modification to PET can start from many aspects, prior art mainly carries out mod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01F6/62D01F6/92D01F1/10D01F11/08C08G63/183

CPCD01F6/62D01F6/92D01F1/10D01F11/08C08G63/183

Inventor 邓颖菁

Owner 胜利油田兴达高祥新材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com