Antibacterial non-woven fabric production line

A production line, non-woven technology, applied in non-woven fabrics, textiles and papermaking, cutting of textile materials, etc., can solve the problems of large physical effort, large energy consumption, inconvenient disassembly, repair or maintenance of rollers, etc. Time saving, high accuracy, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

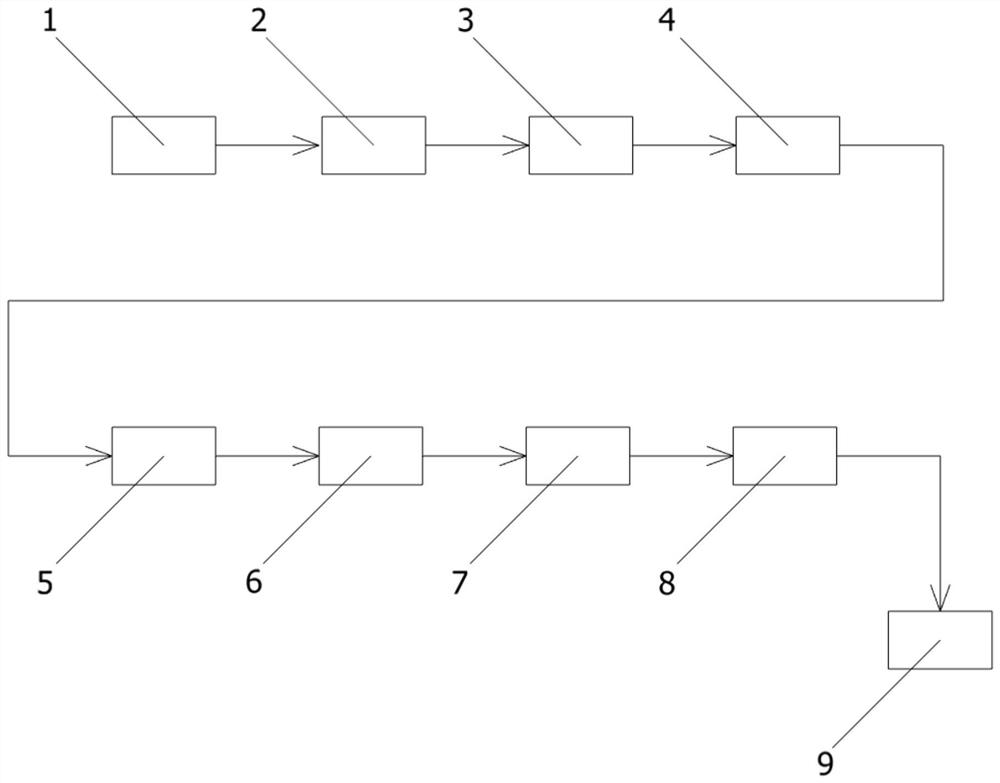

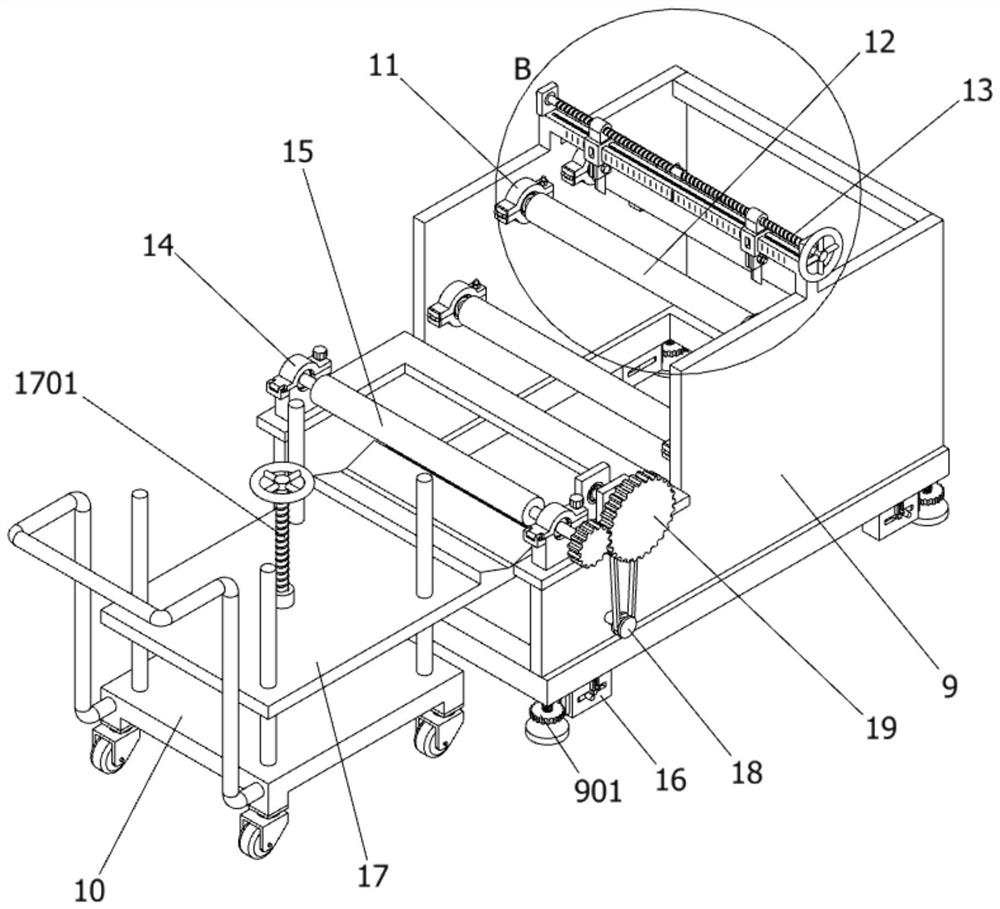

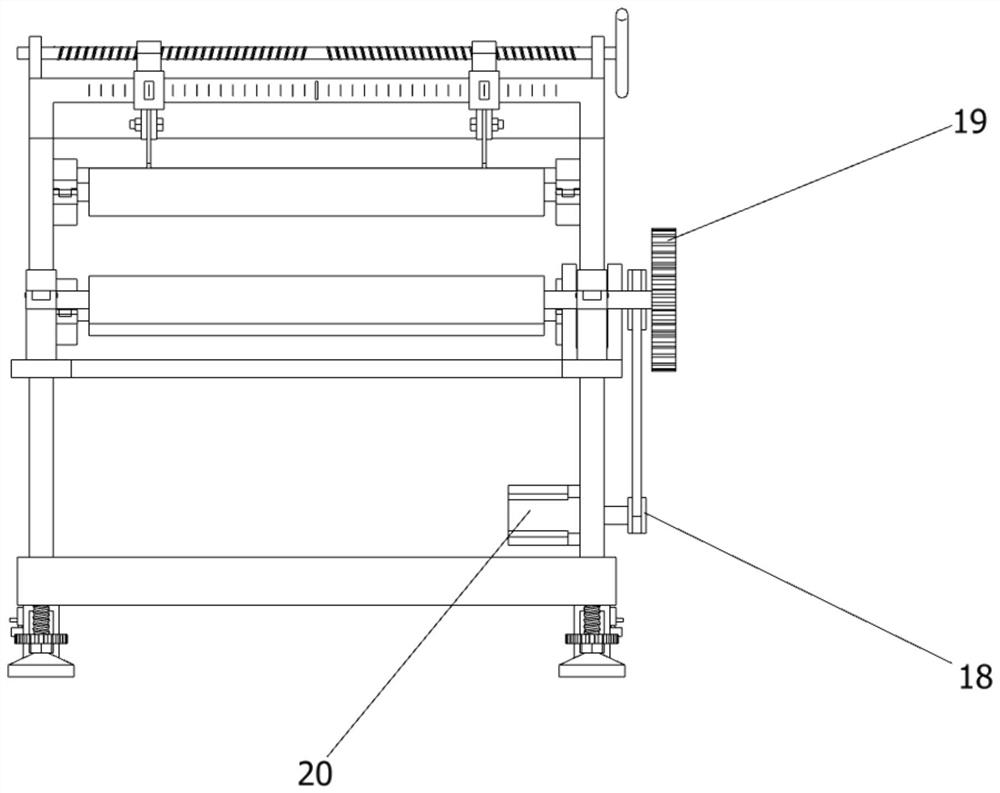

[0036] as attached figure 1 to attach Figure 11 Shown:

[0037] The invention provides an antibacterial non-woven fabric production line, including: feeder 1, opening machine 2, carding machine 3, netting machine 4, acupuncture machine 5, hot rolling machine 6, dryer 7, needle detector 8 and lapping machine 9, the feeding machine 1 is equipped with an opener 2 offline, and the opener 2 is equipped with a carding machine 3 offline; the carding machine 3 is equipped with a netting machine 4 offline, and the netting machine 4 is installed The line is equipped with an acupuncture machine 5; the off-line of the acupuncture machine 5 is equipped with a hot rolling mill 6, and the off-line of the hot rolling mill 6 is equipped with a dryer 7; the off-line of the dryer 7 is equipped with a needle detector 8, and Needle machine 8 off-line is provided with lapping machine 9; , transmission gear 19 and motor 20; a trolley 10 is provided in front of the lapping machine 9, and a liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com