Waste heat boiler for renewable energy storage system

A renewable energy and energy storage system technology, applied in steam generation, water heaters, fluid heaters, etc., can solve the problems of complicated waste heat recovery principles, achieve efficient transfer, uniform heat absorption, and simple principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

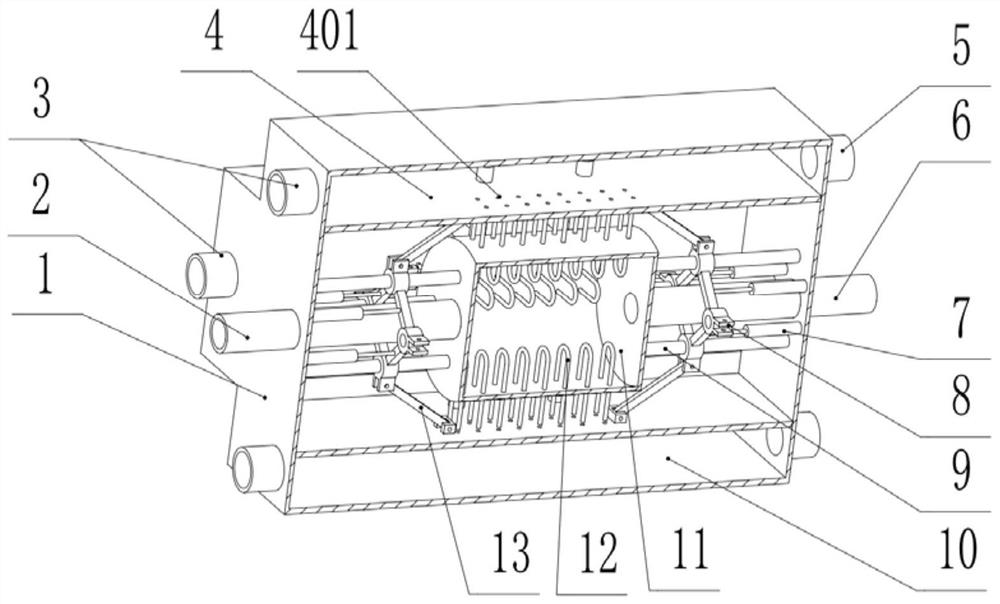

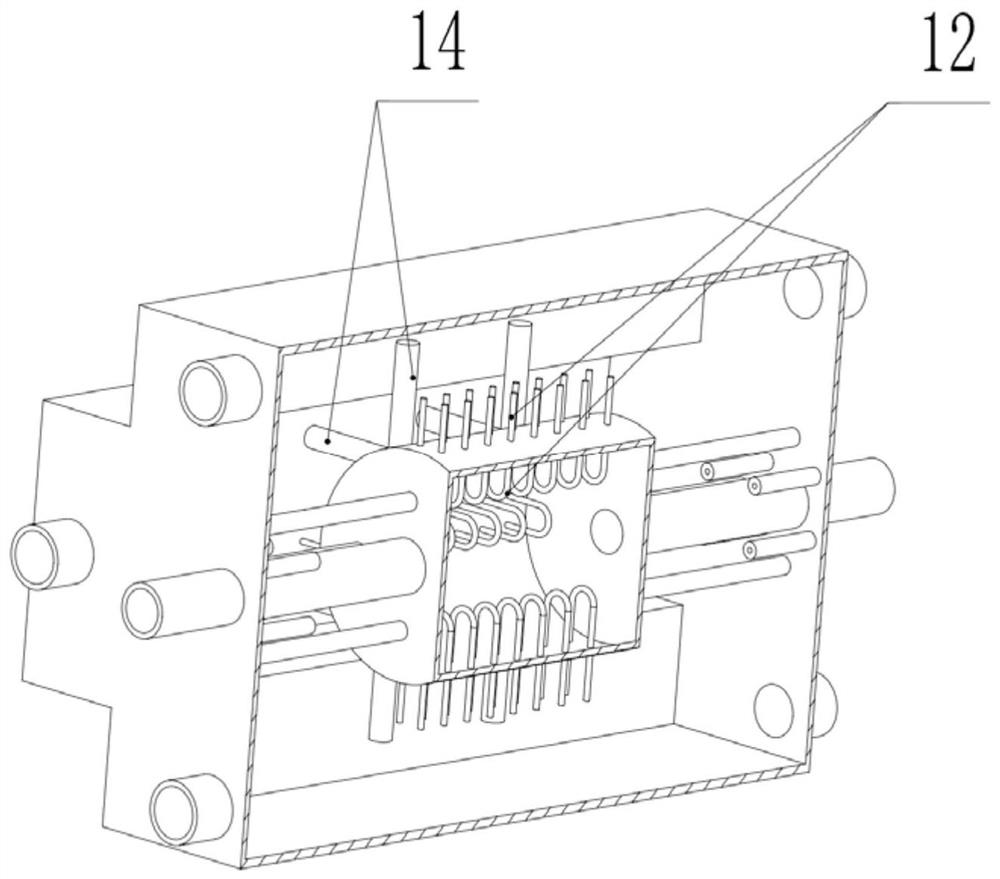

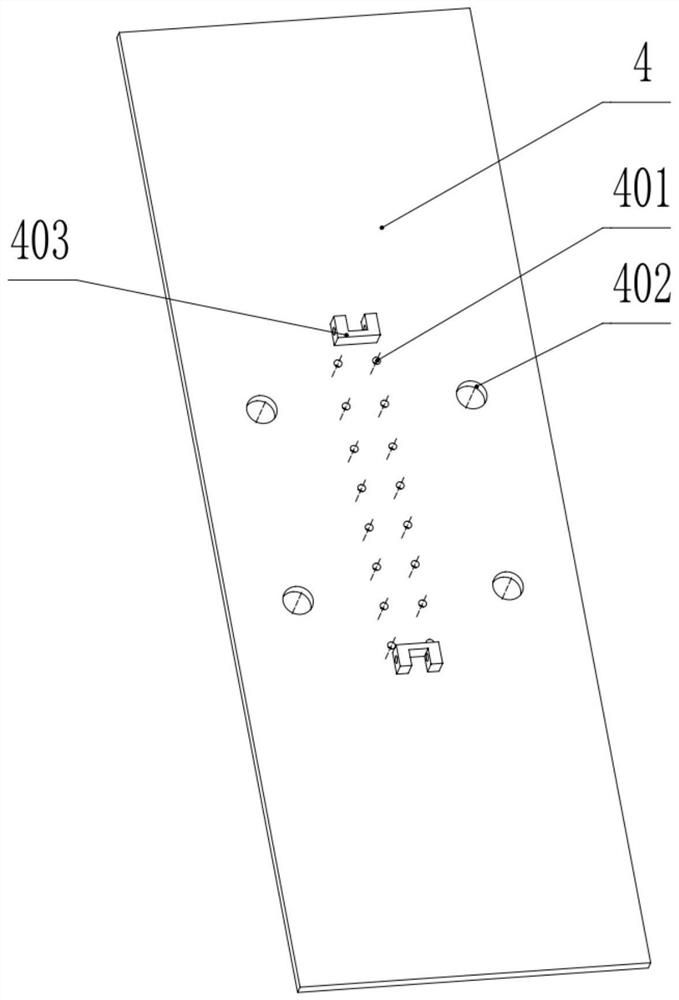

[0019] Example: such as figure 1 , figure 2 , image 3 , Figure 4 A waste heat boiler for a renewable energy storage system is shown, including: a furnace body 1, a water inlet 2, a high-temperature flue gas inlet 3, an isolation plate 4, a flue gas outlet 5, a water outlet 6, a control cylinder 7, and a carriage 8. Carriage guide post 9, flue gas chamber 10, heating furnace 11, superconducting heat rod 12, carriage connecting rod 13, isolation plate guide post 14. One end of the furnace body 1 has a water inlet 2 and a high-temperature flue gas inlet 3 , and the other end of the furnace body 1 has a flue gas outlet 5 and a water outlet 6 . The flue gas enters from the high-temperature flue gas inlet 3, and is released from the flue gas outlet 5 after absorbing heat by the superconducting heat rod 12, and the water enters from the water inlet 2, and is released from the water outlet 6 after being heated to realize continuous heating.

[0020] The superconducting thermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com