Ultrasonic detection reference block for heterogeneous inertia friction weld joint of aero-engine turbine rotor

A technology for aero-engines and comparison test blocks, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problems of different curved surface structures, single structural forms, and artificial defects. Problems such as large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For the function of the comparison test block, the present invention is described in detail by examples.

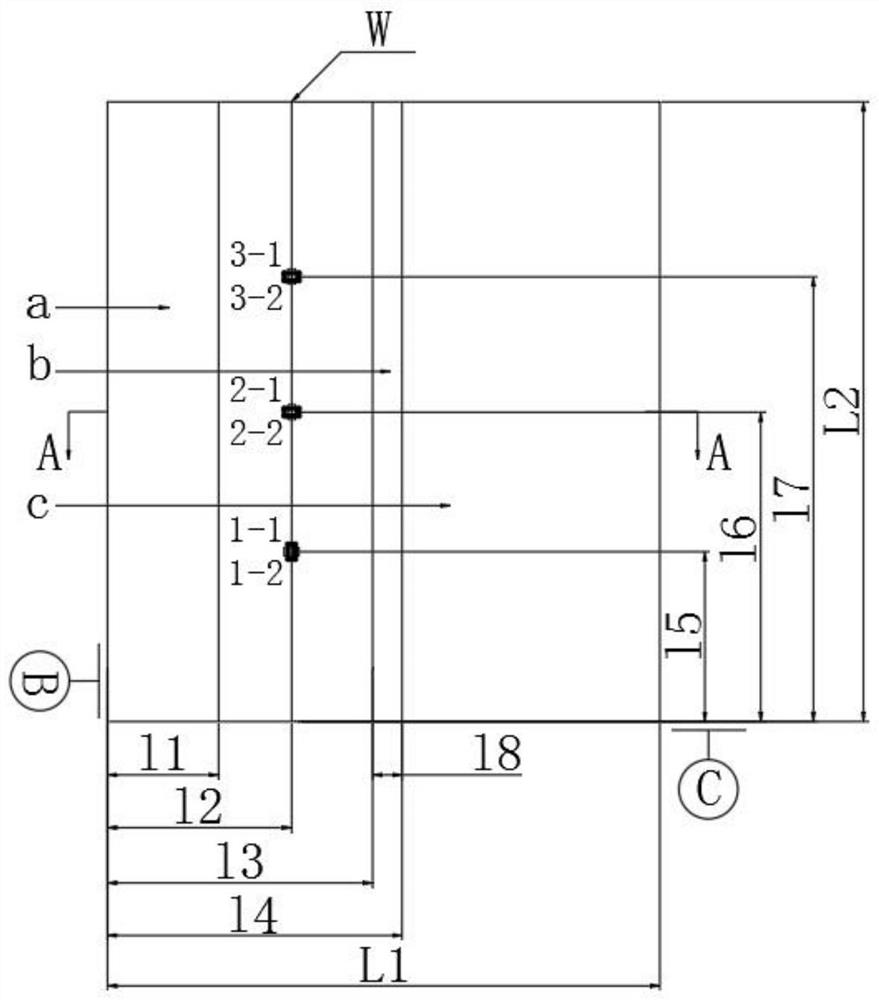

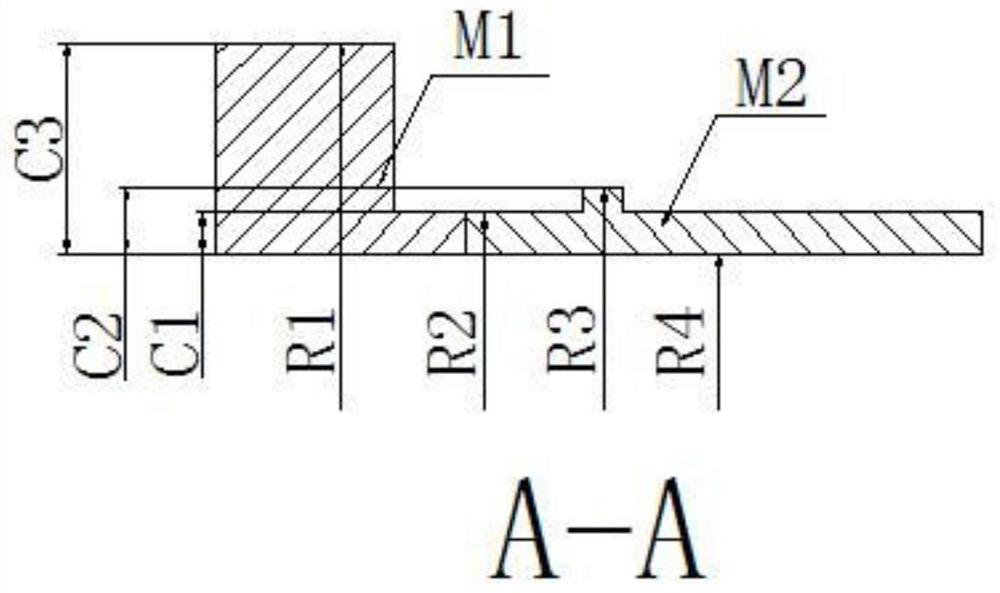

[0018] Such as figure 1 As shown, it is the front view of the design drawing of the comparison test block, figure 2 Design drawings for comparison test blocks, figure 2 for in figure 1 As shown in the axial planing diagram on the basis, the comparative test block for ultrasonic testing of heterogeneous inertial friction welds of turbine rotors includes two parts: the test block body and artificial defects. The welding seam W, the axial dimension of the comparison test block and the radius dimension of the inner and outer surfaces of the arc are exactly the same as the inertial friction weld of the workpiece to be tested.

[0019] Such as figure 1As shown, the comparison test block for ultrasonic testing of heterogeneous inertial friction welds of aero-engine turbine rotors is characterized in that: the inner and outer surfaces of the comparison test block are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com