Direct type backlight module

A backlight module, direct type technology, applied in the fields of optics, nonlinear optics, instruments, etc., can solve the problems of high manufacturing cost, difficult implementation of flexible Mini-LED backlight technology, low yield, etc., to avoid light loss, improve The effect of light energy utilization and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

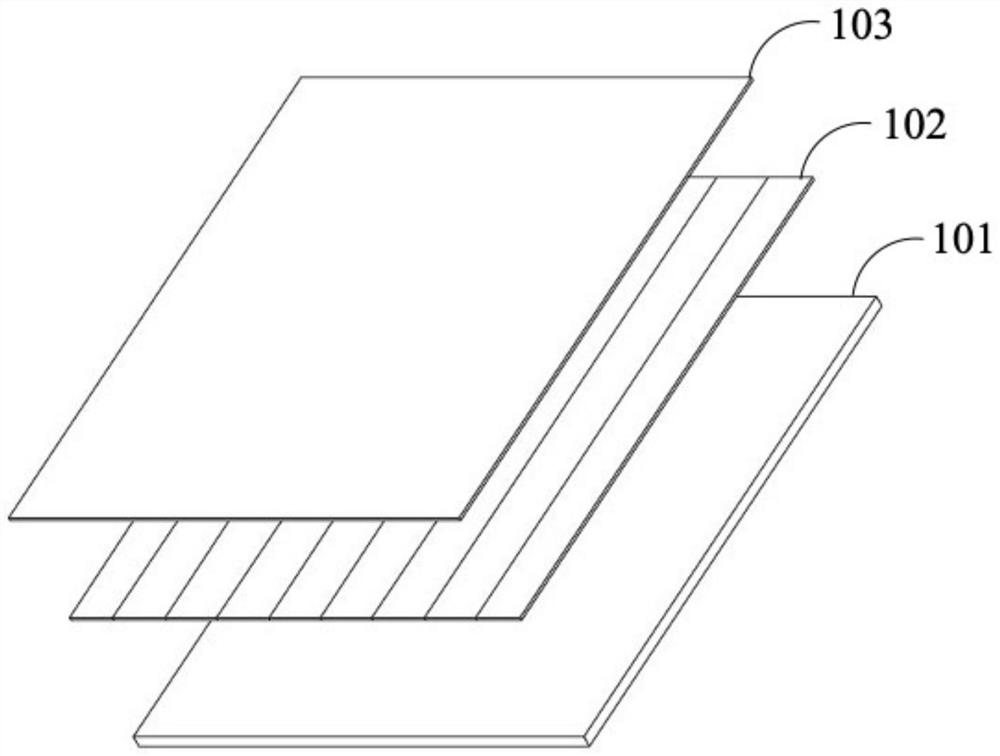

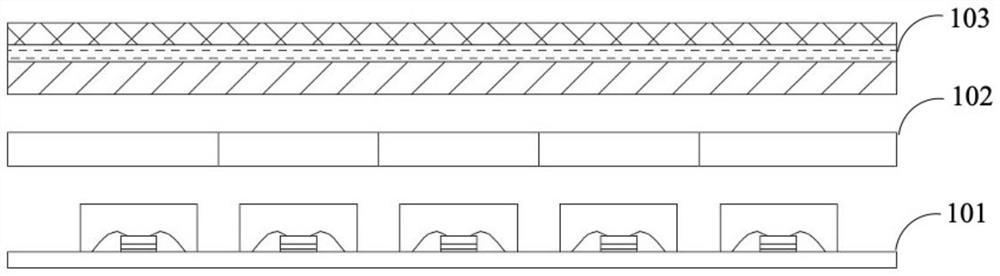

[0027] First, through figure 1 , the direct type backlight device according to Embodiment 1 of the present invention will be described. The direct-lit backlight module of the present invention includes a bottom-up blue LED lamp panel 101, a fluorescent film 102 and an optical film set 103;

[0028] Wherein, the fluorescent film includes at least:

[0029] a first light conversion mechanism whose second color light is green;

[0030] A second light conversion mechanism, the third color of which is red;

[0031] Wherein, the first light conversion mechanism and the second light conversion mechanism are alternately arranged, and the first light conversion mechanism and the second light conversion mechanism use quantum dots to realize light wavelength conversion of LED blue light.

[0032] The present invention does not need to arrange LED chips emitting light in multiple colors of RGB, but only needs to arrange blue LED chips on the blue LED lamp board, thus greatly improving ...

Embodiment 2

[0036] In the following, only the differences between Embodiment 3 and Embodiment 1 will be described, and the similarities will not be repeated here.

[0037] The second light emission of the first light conversion element is yellow. In other words, the red, yellow and blue RYB three-pixel light emission constitutes a three-color light source.

Embodiment 3

[0039] In the following, only the differences between Embodiment 3 and Embodiment 1 will be described, and the similarities will not be repeated here.

[0040] The first light conversion mechanism and the second light conversion mechanism are respectively arranged on two fluorescent films, which are spliced together by optical glue to form an integral fluorescent film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com