Cutter changing control method for hob of shield tunneling machine in composite stratum

A technology of composite formation and control method, which is applied in the fields of earthwork drilling, complex mathematical operations, resources, etc., can solve problems such as affecting construction efficiency, inability to comprehensively judge the degree of hob wear, and delaying the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

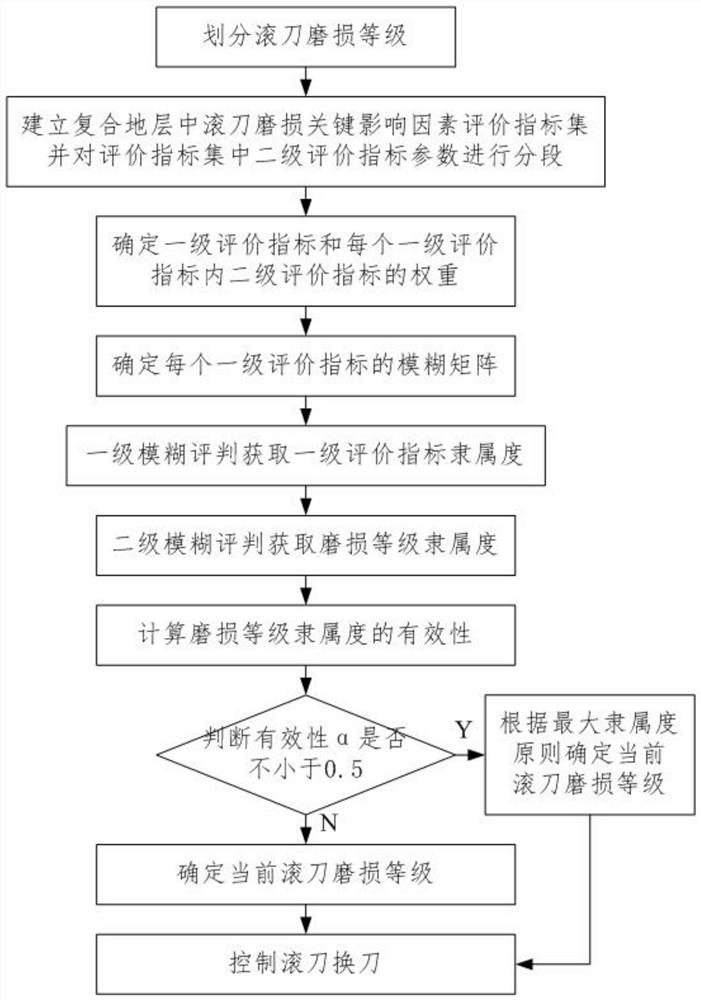

[0065] Such as figure 1 As shown, a shield machine hob tool change control method in a complex formation of the present invention includes the following steps:

[0066] Step 1. Divide the hob wear level: set the hob wear warning value. When the hob wear amount does not reach half of the wear warning value, the state is a small amount of hob wear, and a small amount of hob wear is regarded as a first-level wear level;

[0067] When the wear amount of the hob exceeds half of the wear warning value and does not reach the wear warning value, this state is general wear of the hob, and the general wear of the hob is regarded as a secondary wear level;

[0068] When the wear amount of the hob reaches the wear warning value, this state is significant wear of the hob, and the significant wear of the hob is regarded as a third-level wear level;

[0069] When the wear amount of the hob exceeds the wear warning value, this state is serious wear of the hob, and the severe wear of the hob ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com