Ultrasonic bottle wall cleaning machine for cleaning medicine bottles

An ultrasonic and washing machine technology, applied in cleaning methods and utensils, dryers for static materials, dryers, etc., can solve problems such as harming the health of patients, reducing the appearance qualification rate, and reducing the product qualification rate, and achieves elimination. The effect of eliminating hidden dangers, reducing the intensity of bottle handling, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

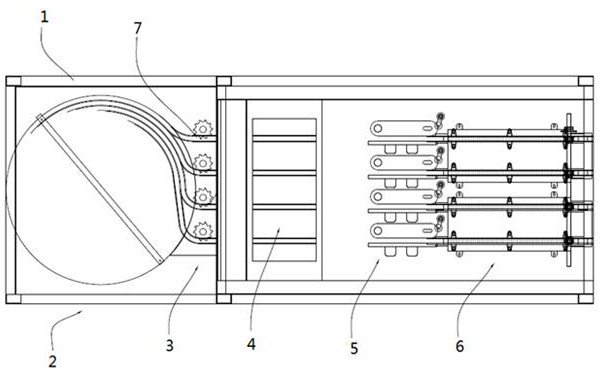

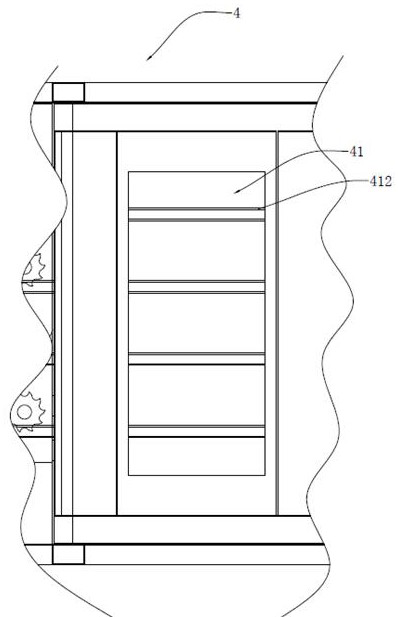

[0032] refer to figure 1 , an ultrasonic bottle wall cleaning machine for medicine bottle cleaning according to the present invention, comprising a frame 1, the outer dimension of the frame 1 is 3100mm×1200mm×1750mm, and the frame 1 is provided with bottle unscramblers in sequence along the medicine bottle conveying direction. Device 2, equidistant bottle pulling device 3, ultrasonic cleaning device 4, water-absorbing wiping device 5 and outer wall drying device 6, four conveyor belts 7 are arranged in parallel on the frame 1, and the conveyor belts 7 pass through the equidistant bottle pulling device in turn 3. Ultrasonic cleaning device 4, water-absorbing wiping device 5 and outer wall drying device 6, to carry out various processes step by step by transferring medicine bottles.

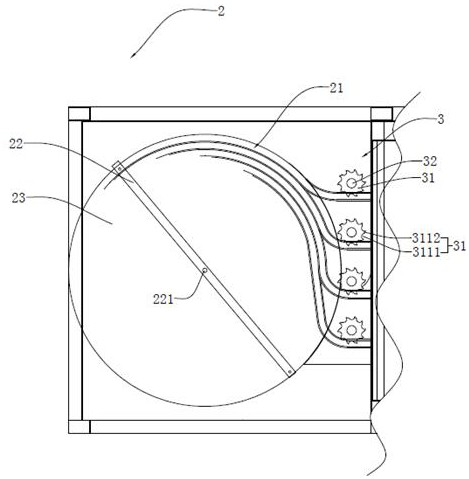

[0033] refer to figure 1 with figure 2 , the bottle unscrambling device 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com