Equipment for manufacturing large-caliber bellmouth and flaring plastic pipe

A technology for pipes and bearings, applied in the field of plastic pipe production equipment, can solve the problems of increasing production costs, restricting the development of enterprises, and difficult to unify the hoop stiffness of the pipe body and the flaring part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

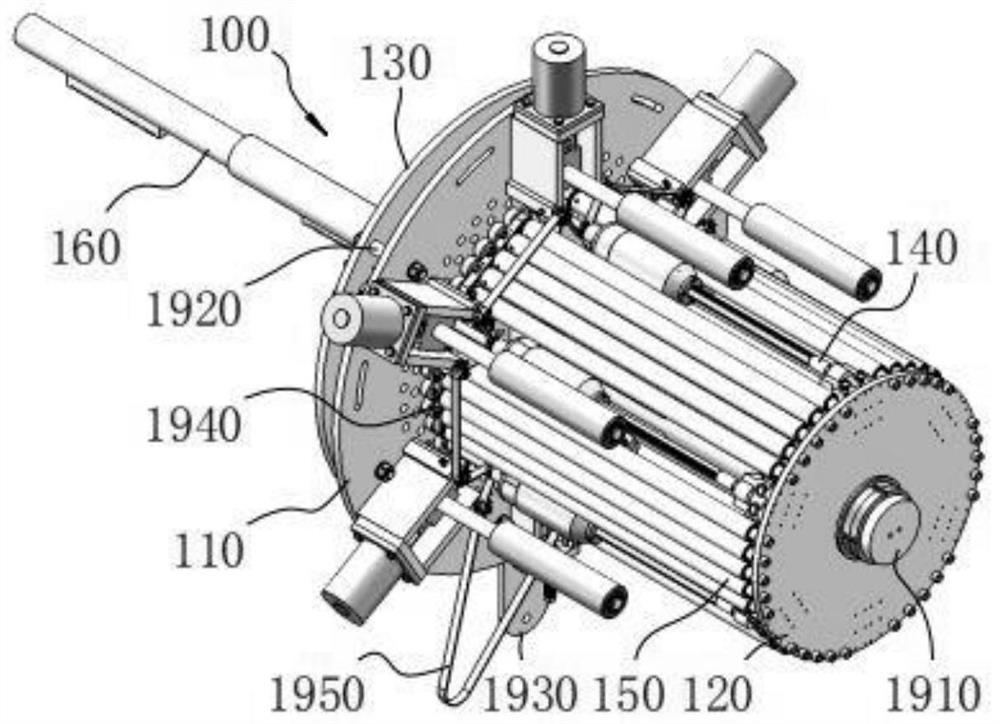

[0112] This embodiment is explained and explained in detail in conjunction with the accompanying drawings of the description. The structural division of the device is for the sake of explanation. In some cases, it is reasonable. Due to the limitation of language logic, the technical expression is not absolutely reasonable. One thing the public should understand and know.

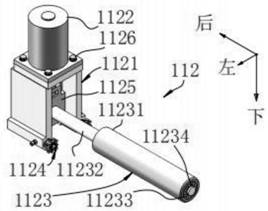

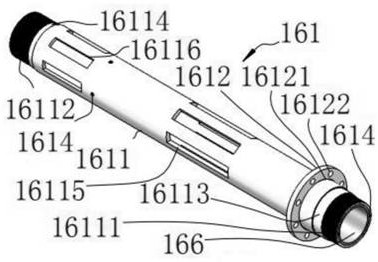

[0113] For the convenience of description, the equipment structure is divided. Part 100 is the linkage mechanism for pipe winding and flaring, Part 200 is the strip stress relief mechanism, Part 300 is the frame mechanism, and Part 400 is the winding tensioner assembly. The 500 part is the flaring tension sprocket assembly, the 600 part is the winding pressure roller assembly, the 700 part is the socket pressure roller assembly, the 800 part is the rear mold disc helix angle adjustment assembly, and the 900 part is the hot air system. The three-dimensional space is defined, and the upper, lower, left, right,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com