Ascending and descending operation and belt breakage detection method of elevator

A detection method and a lifting belt technology, which are applied in lifting frames, lifting devices, transportation and packaging, etc., can solve the problem of inability to effectively increase the lifting speed of the loading platform, the positioning accuracy of lifting equipment such as the loading platform is not high, and the operating height Difficult to accurately control and other problems, to achieve objective and effective monitoring results, optimize and improve the operation speed, and improve the effect of modular and lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

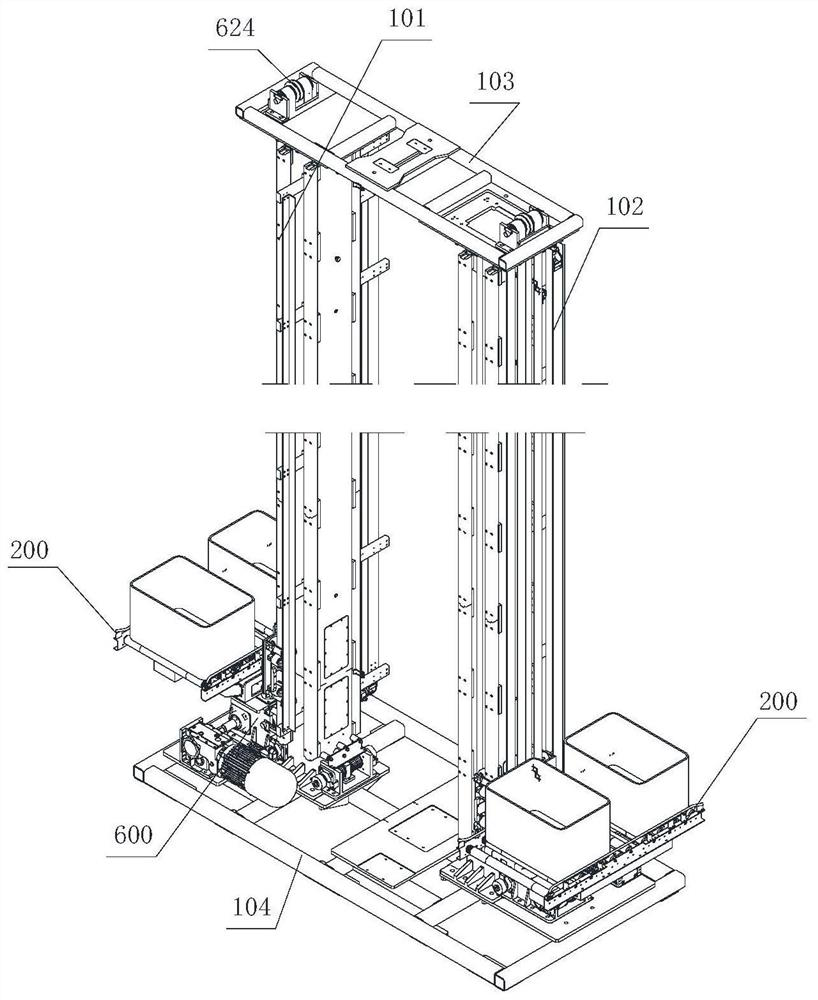

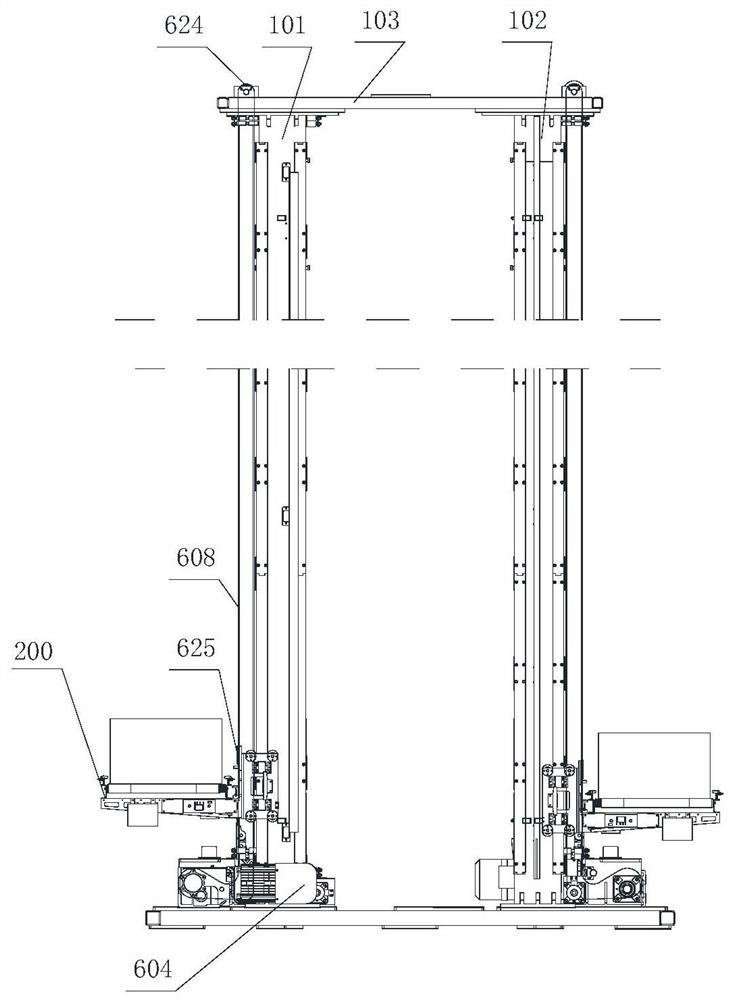

[0025] Example 1, such as figure 1 and figure 2 As shown, the present application proposes the following structural improvement of the hoist and the lifting operation and broken belt detection method realized by using the hoist.

[0026] The hoist includes a basic frame composed of a left column 101, a right column 102, an upper beam 103 and a lower beam 104, which ensure the overall rigidity of the hoist and the accuracy of lifting operation.

[0027] Cargo platforms 200 are arranged on the sides of the left column 101 and the right column 102 respectively, and the two cargo platforms 200 are respectively connected to two groups of lifting transmission assemblies 600 with the same structure and arranged symmetrically along the columns.

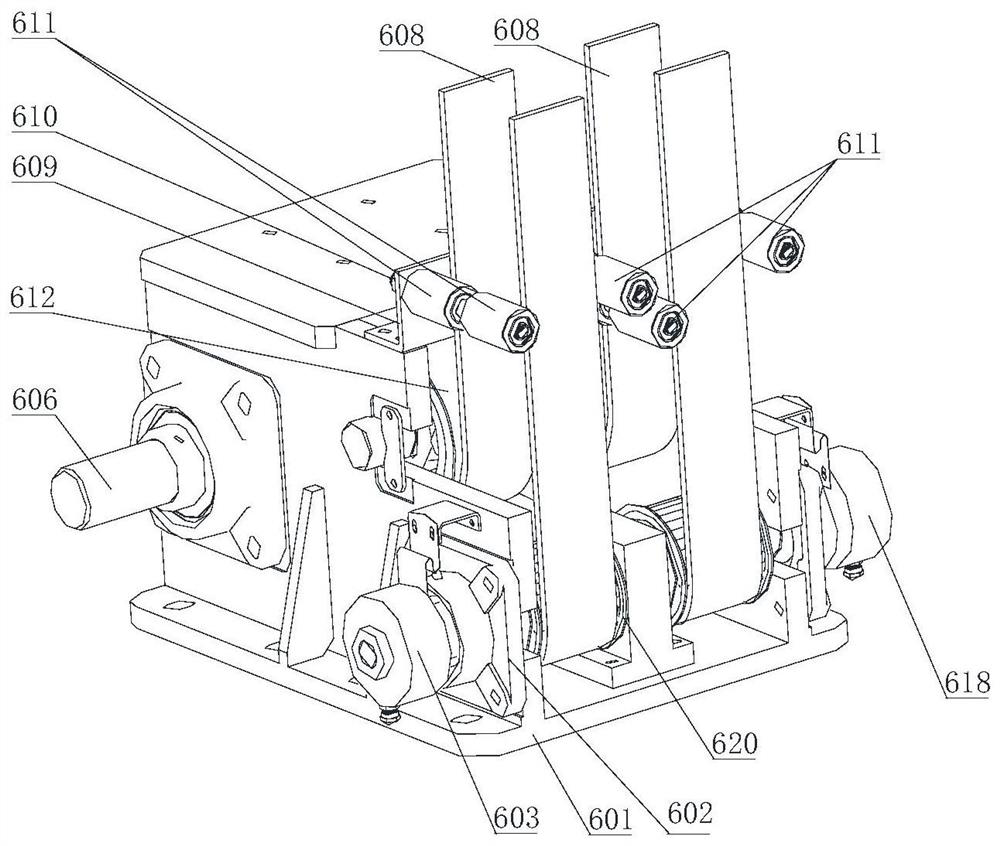

[0028] The lifting transmission assembly 600 includes two sets of lifting belts 608 driven by a set of servo motors 604 . Each set of lifting belts 608 bypasses the driven sheave 624 installed on the upper cross beam 103 , and is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com