Cracked green glaze and preparation method thereof

A production method, green glaze technology, applied in the field of enamel, can solve the problems of unsatisfactory color and luster and enamel, imprecise temperature control, different formulas, etc., and achieve the effect of good artistic appreciation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

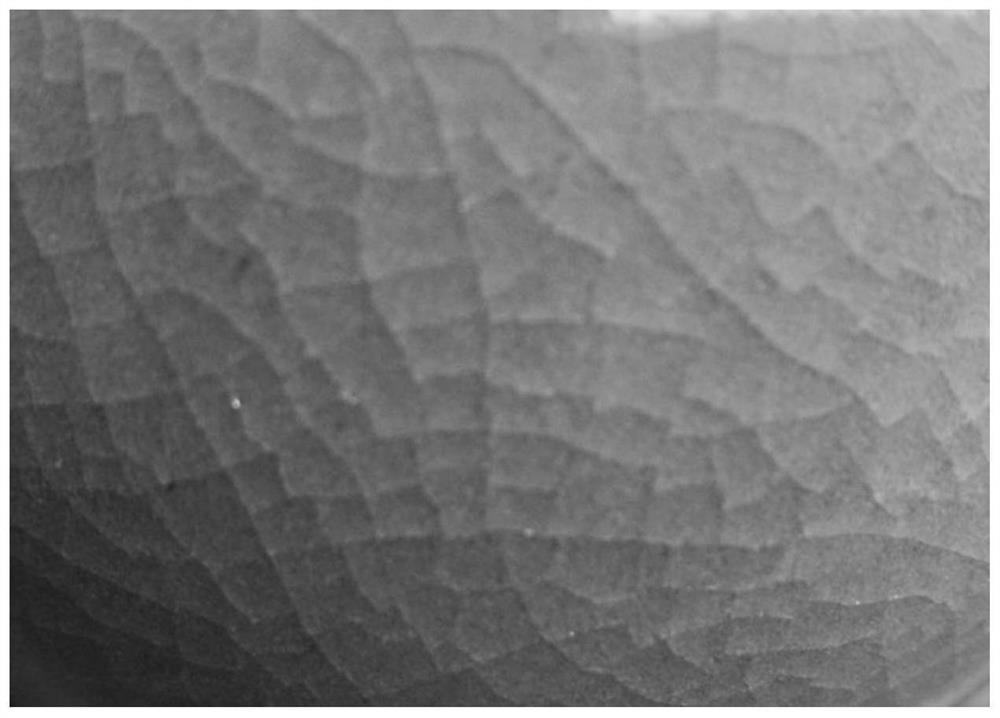

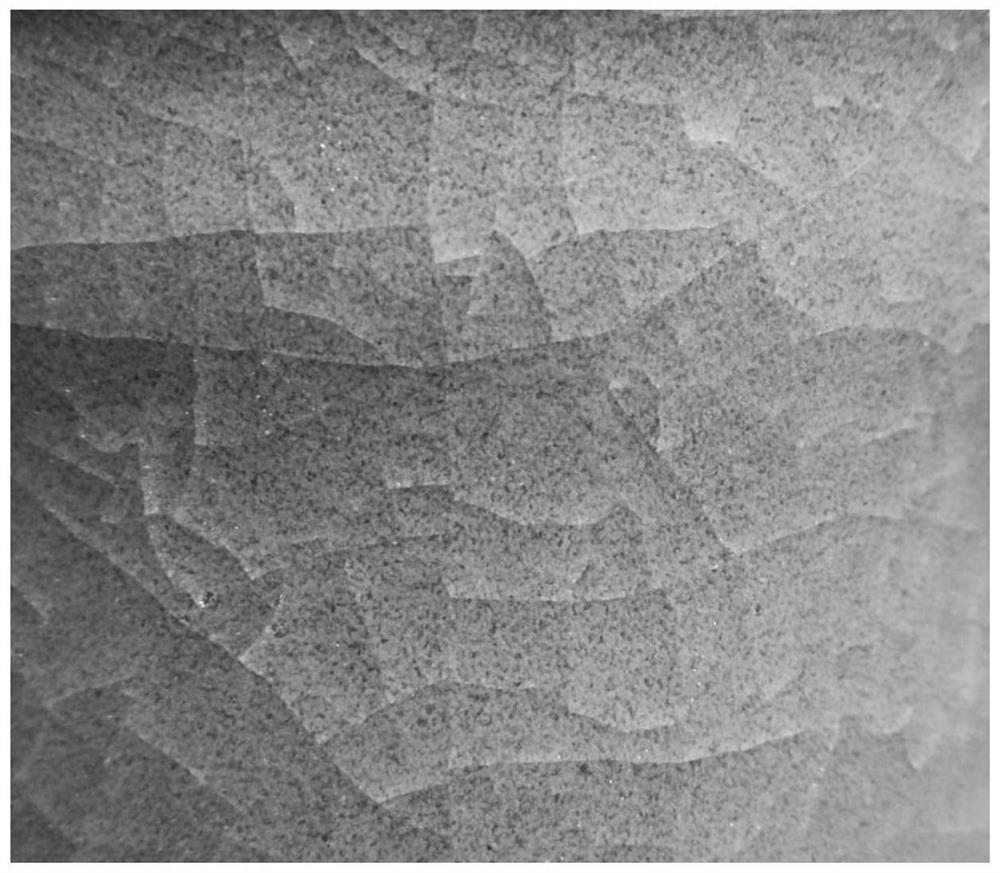

Image

Examples

Embodiment 1

[0036] (1) Broken and sieved

[0037] Pingjiang red soil, Hongqiao feldspar, wollastonite, calcite, and mica are crushed and sieved separately, and can be crushed by a wheel mill and sieved through a 100-200 mesh sieve.

[0038] (2) Raw material mixing

[0039] Get the Pingjiang red soil of 40 parts by weight, the Hongqiao feldspar of 20 parts by weight, the plant ash of 12 parts by weight, the wollastonite of 5 parts by weight, the calcite of 2 parts by weight, the calcium oxide of 6 parts by weight and the copper oxide of 7 parts by weight, 8 parts by weight of mica were mixed.

[0040] (3) Wet ball milling

[0041] Put the mixed raw materials in step (2) into a ball mill, according to the material: water: ball = 1:0.5:1.5, wet ball milling for 10 to 15 hours.

[0042] (4) Preparation of glaze slurry

[0043] The ball-milled glaze is passed through a 100-200 mesh sieve and then adjusted into a 50-80 Baume degree glaze slurry.

[0044] (5) Glaze firing

[0045] Take the...

Embodiment 2

[0048] (1) Broken and sieved

[0049] Pingjiang red soil, Hongqiao feldspar, wollastonite, calcite, and mica are crushed and sieved separately, and can be crushed by a wheel mill and sieved through a 100-200 mesh sieve.

[0050](2) Raw material mixing

[0051] Get the Pingjiang red soil of 35 parts by weight, the Hongqiao feldspar of 22 parts by weight, the plant ash of 12 parts by weight, the wollastonite of 5 parts by weight, the calcite of 2 parts by weight, the calcium oxide of 6 parts by weight and the copper oxide of 10 parts by weight, 8 parts by weight of mica were mixed.

[0052] (3) Wet ball milling

[0053] Put the mixed raw materials in step (2) into a ball mill, according to the material: water: ball = 1:0.5:1.5, wet ball milling for 10 to 15 hours.

[0054] (4) Preparation of glaze slurry

[0055] The ball-milled glaze is passed through a 100-200 mesh sieve and then adjusted into a 50-80 Baume degree glaze slurry.

[0056] (5) Glaze firing

[0057] Take the...

Embodiment 3

[0060] (1) Broken and sieved

[0061] Hongqiao feldspar, quartz, Pingjiang laterite, and calcite are crushed and sieved separately, and can be crushed with a wheel mill and then sieved through a 100-200 mesh sieve.

[0062] (2) Raw material mixing

[0063] Get the Pingjiang red soil of 30 parts by weight, the Hongqiao feldspar of 30 parts by weight, the plant ash of 8 parts by weight, the wollastonite of 5 parts by weight, the calcite of 4 parts by weight, the calcium oxide of 8 parts by weight and the copper oxide of 8 parts by weight, 7 parts by weight of mica were mixed.

[0064] (3) Wet ball milling

[0065] Put the mixed raw materials in step (2) into a ball mill, according to the material: water: ball = 1:0.5:1.5, wet ball milling for 10 to 15 hours.

[0066] (4) Preparation of glaze slurry

[0067] The ball-milled glaze is passed through a 100-200 mesh sieve and then adjusted into a 50-80 Baume degree glaze slurry.

[0068] (5) Glaze firing

[0069] Take the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com