Weather-proof nail-free glue capable of being used outdoors and preparation method of weather-proof nail-free glue

A nail-free adhesive and weather-resistant technology, applied in adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor aging resistance, poor nail-free adhesive aging resistance, unusable effects, etc., to achieve system environmental protection , Excellent aging performance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

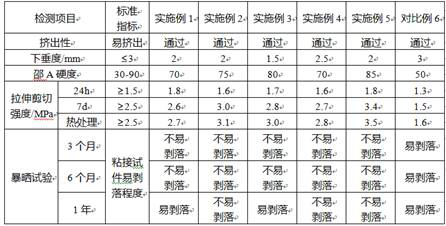

Examples

Embodiment 1

[0043] ①Rubber mastication:

[0044] 20 parts of chloroprene rubber and 10 parts of chlorosulfonated polyethylene rubber are plasticized according to the proportion by weight, and shredded for use;

[0045] ②Preparation of nail-free glue mother liquor:

[0046] According to the proportion by weight, the mixed rubber obtained in ①, 50 parts of HDBE, 12.5 parts of FC-36, 12.5 parts of NCC, 1 part of activated magnesium oxide, 7 parts of p-tert-butylphenol formaldehyde resin, 24 parts of C5 petroleum resin, 0.1 Put 0.5 part of coupling agent and 0.5 part of antioxidant into the reaction kettle, turn on the cooling water, disperse, and stir well to obtain the nail-free glue mother solution.

[0047] ③ Preparation of weather-resistant nail-free glue for outdoor use:

[0048] S1. According to the proportion by weight, put 90 parts of nano-calcium carbonate and 15 parts of titanium dioxide into the nail-free glue mother liquor prepared in ② several times, turn on the cooling water,...

Embodiment 2

[0051] ①Rubber mastication:

[0052] 30 parts of chloroprene rubber and 10 parts of chlorosulfonated polyethylene rubber are plasticized according to the proportion by weight, and shredded for use;

[0053] ②Preparation of nail-free glue mother liquor:

[0054] According to the proportion by weight, the mixed rubber obtained in ①, 50 parts of HDBE, 17.8 parts of FC-36, 17.8 parts of NCC, 1.5 parts of activated magnesium oxide, 8 parts of p-tert-butylphenol formaldehyde resin, 10 parts of C5 petroleum resin, 15 parts Put 1 part of C9 petroleum resin, 0.15 part of coupling agent, and 0.55 part of antioxidant into the reaction kettle, turn on the cooling water, disperse, and stir well to obtain the nail-free glue mother solution.

[0055] ③ Preparation of weather-resistant nail-free glue for outdoor use:

[0056] S1. According to the proportion by weight, put 45 parts of nano-calcium carbonate, 45 parts of fumed silica, 10 parts of titanium dioxide, and 10 parts of aluminum sil...

Embodiment 3

[0059] ①Rubber mastication:

[0060] 25 parts of chloroprene rubber, 6 parts of chlorosulfonated polyethylene rubber, and 6 parts of EPDM rubber are plasticized according to the weight ratio, and shredded for use;

[0061] ②Preparation of nail-free glue mother liquor:

[0062] According to the proportioning by weight, the mixed rubber obtained in ①, 42.5 parts of HDBE, 21.2 parts of FC-36, 21.2 parts of NCC, 1.2 parts of active magnesium oxide, 9 parts of p-tert-butylphenol formaldehyde resin, 15 parts of C5 petroleum resin, 15 parts 1 part of terpene resin, 0.2 part of coupling agent, and 0.6 part of antioxidant are put into the reactor, turn on the cooling water, disperse, and stir well to obtain the nail-free glue mother solution.

[0063] ③ Preparation of weather-resistant nail-free glue for outdoor use:

[0064] S1. According to the proportion by weight, put 50 parts of nano-calcium carbonate, 50 parts of fumed silica, and 15 parts of aluminum silver powder into the nai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com