Viscoelastic particle oil displacement agent with water plugging function

A viscoelastic and oil-displacing agent technology, applied in the field of viscoelastic particle oil-displacing agent, can solve the problems of ineffective improvement of oil displacement efficiency and low sweep coefficient of strongly heterogeneous oil layers, so as to improve the oil-water mobility ratio, increase the Oil displacement efficiency, the effect of oil displacement efficiency increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. This material is a binary polymer synthesized from main raw materials (20% acrylic acid + 18% acrylamide). Cross-linking agent: N, N'-dimethylene isobutyramide (0.03%), initiator: Butanox M-50 (0.05%), general-purpose methyl ethyl ketone peroxide (MEKP), purchased from Nouryon Nouryon polymer chemical company. Add 65% mass of silica gel of binary polymer, mix and disperse into bead-shaped particles with different particle sizes, mix evenly and cool, then pack into bags.

[0020] 2. The acrylic acid + acrylamide binary polymer of this material is acrylic acid (20%), acrylamide (18%), crosslinking agent (N, N'-dimethylene isobutyramide) (0.03%), Al 3+ (0.03%), initiator (m-50) (0.05%), mixed uniformly in water, heated to 60 degrees for 2 hours, and then heated to 80 degrees for 2 hours.

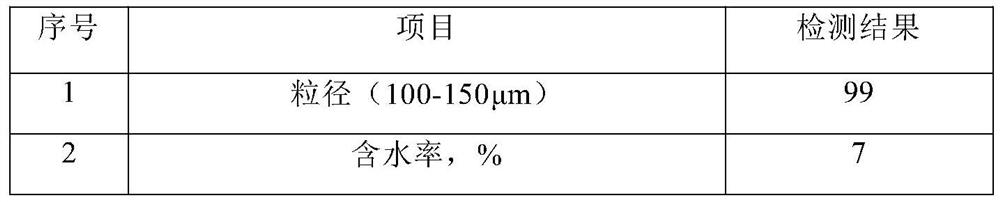

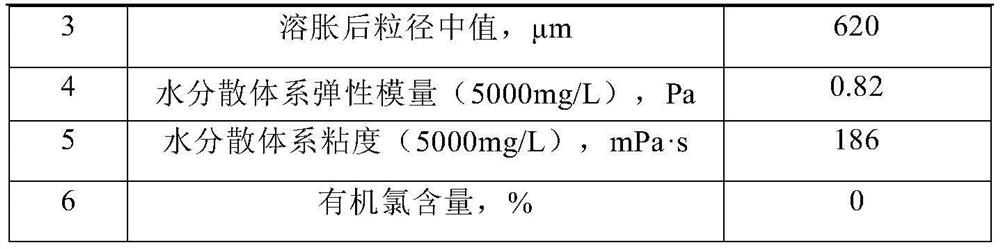

[0021] Carry out the performance evaluation of key indicators to the above-mentioned oil-displacing agent product made, the performance evaluation result is shown in the following t...

Embodiment 2

[0027] 1. This material is a binary polymer synthesized from main raw materials (18% acrylic acid + 16% acrylamide). Cross-linking agent: N, N'-dimethylene isobutyramide (0.05%); initiator (ammonium persulfate 0.2%+Butanox M-50) (0.02%). 70% by weight of the binary polymer is added to the silicon dioxide gel, which is cut into pieces, dried, crushed and sieved to obtain particles with different particle sizes, and then packed into bags.

[0028] 2. The acrylic acid + acrylamide binary polymer of this material is acrylic acid (18%), acrylamide (16%), crosslinking agent (N, N'-dimethylene isobutyramide) (0.05%), Al 3+ (0.03%), initiator (ammonium persulfate 0.2%+ButanoxM-50) (0.02%), mixed uniformly in water, heated to 70 degrees for 3 hours, then heated to 90 degrees for 2 hours.

[0029] Carry out the performance evaluation of key indicators to the above-mentioned oil-displacing agent product made, the performance evaluation result is shown in the following table:

[0030] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com