Preparation method of high-linoleic-acid safflower seed oil

A technology of safflower seed oil and high linoleic acid, which is applied in the fields of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of high extraction cost, inconvenient industrial large-scale production, low production capacity, etc., and achieve extraction The effect of low cost, less impurities and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

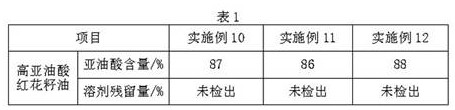

Image

Examples

Embodiment 1

[0019] Embodiment 1: The preparation method of the high linoleic acid safflower seed oil is carried out according to the following steps: the first step, the safflower seed powder is added to No. 6 extraction solvent oil for extraction and stirring, and the extract is obtained after separation In the second step, the obtained extract is concentrated under reduced pressure and stirred to obtain safflower seed crude oil; in the third step, the obtained safflower seed crude oil is extracted with supercritical carbon dioxide and separated from impurities to obtain high linoleic acid Safflower oil.

[0020] The above No. 6 extraction solvent oil was provided by Shandong Yanshuo Chemical Co., Ltd.

Embodiment 2

[0021] Embodiment 2: As an optimization of the above embodiment, the weight ratio of safflower seed powder to No. 6 extraction solvent oil is 1:1.1 to 2.0.

Embodiment 3

[0022] Example 3: As an optimization of the above example, in the first step, countercurrent extraction is used for extraction, the extraction temperature is 40°C to 55°C, and the stirring speed is 0.3r / h to 1.0r / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com