Crack-control anti-corrosion prefabricated steel-concrete composite comprehensive pipe rack

A technology of integrated pipe gallery and reinforced concrete slab, applied in water conservancy projects, artificial islands, building components, etc., to shorten the construction period, reduce material costs, and improve economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below figure 1 ~8 describe the embodiment of the present invention in detail.

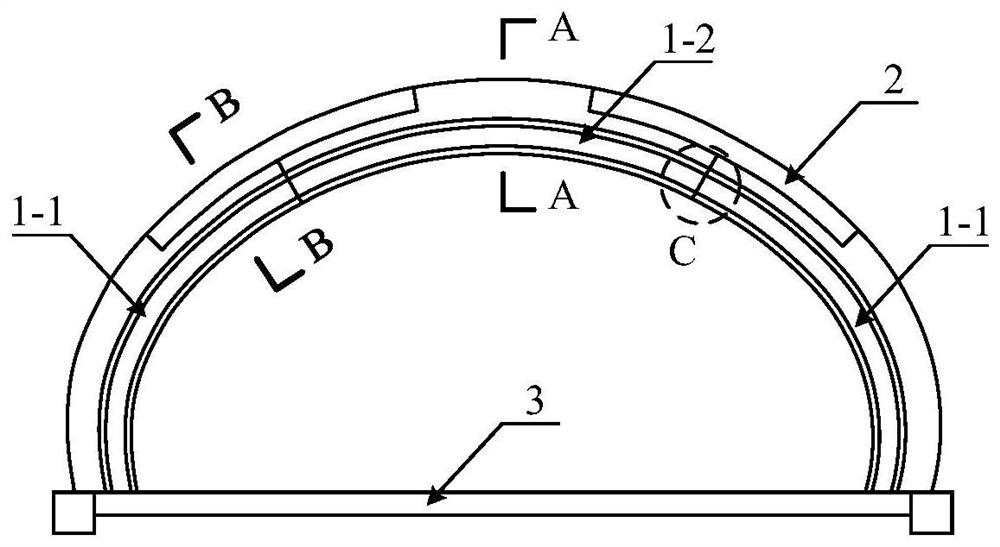

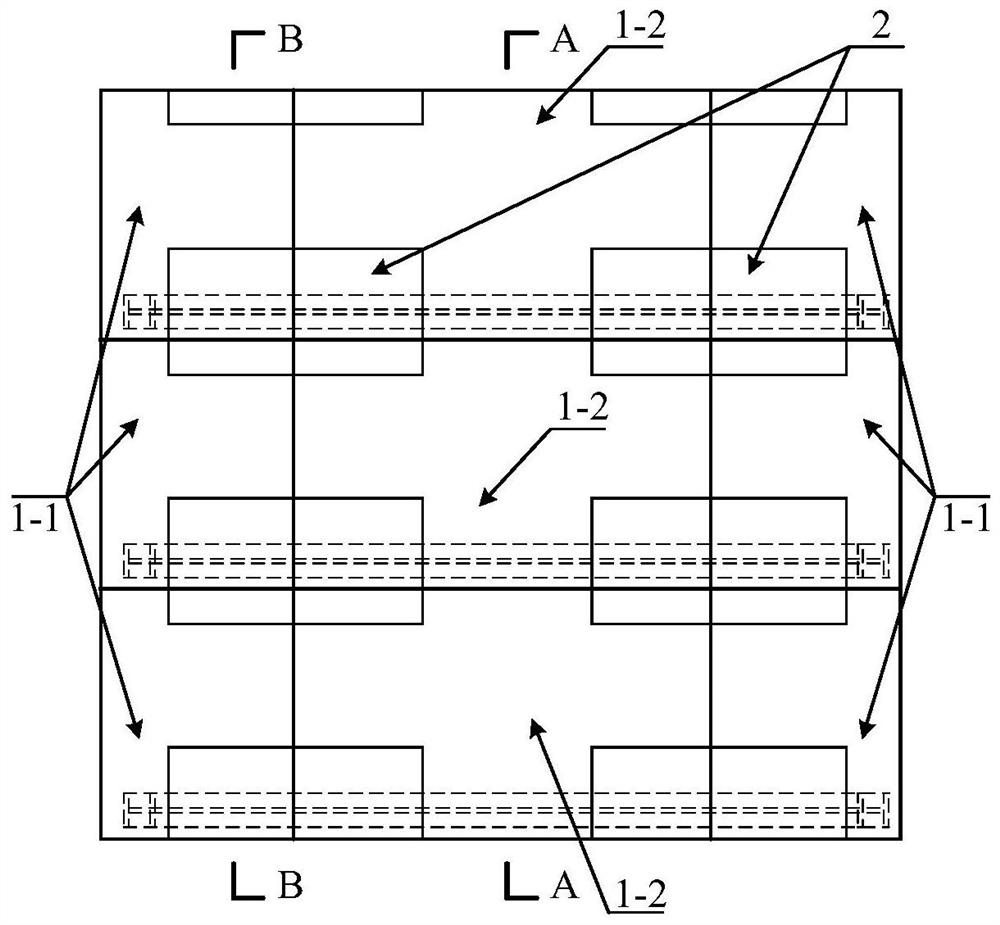

[0034] Such as Figure 1~2 As shown, a prefabricated steel-concrete composite pipe gallery with crack control and anti-corrosion is composed of prefabricated parts, cast-in-place ultra-high toughness cement-based composite material 2, and concrete base 3; prefabricated part 1 includes bottom prefabricated parts 1-1 There are two types of top prefabricated parts 1-2; the comprehensive pipe gallery structure is supported on the concrete base 3.

[0035] Such as figure 2 As shown, the horizontal section of the structure is assembled by two bottom prefabricated parts 1-1 and one top prefabricated part 1-2 to form an arched cross-section; the longitudinal direction of the structure is formed by continuously assembling the formed arched cross-sectional units to reach the length that meets the design requirements.

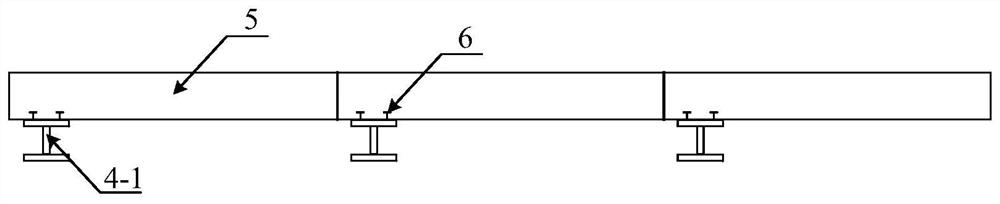

[0036] Such as Figure 3-1~3-2 , Figure 4-1~4-2 , Figure 5-1~5-2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com