Disposal system and method for combustible industrial solid wastes

A solid waste and disposal system technology, which is applied in the direction of combustion methods, combustion product treatment, chemical instruments and methods, etc., can solve the problems of polluting the environment, affecting the daily life of people around the dump, affecting sustainable development and social stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A disposal system for combustible industrial solid waste,

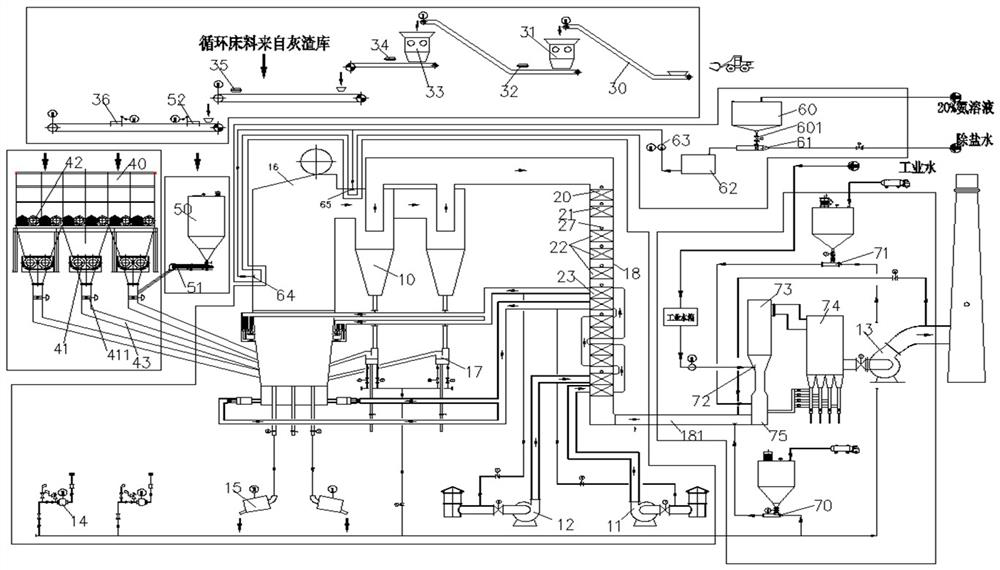

[0071] See figure 1 , the system includes a circulating fluidized bed boiler, a crushing and conveying device, a feeding device in front of the furnace, a bed material conveying device, a secondary SNCR denitrification device and a flue gas treatment subsystem. The flue gas treatment subsystem is used for flue gas deacidification, Heavy metal removal, dioxin removal and dust removal;

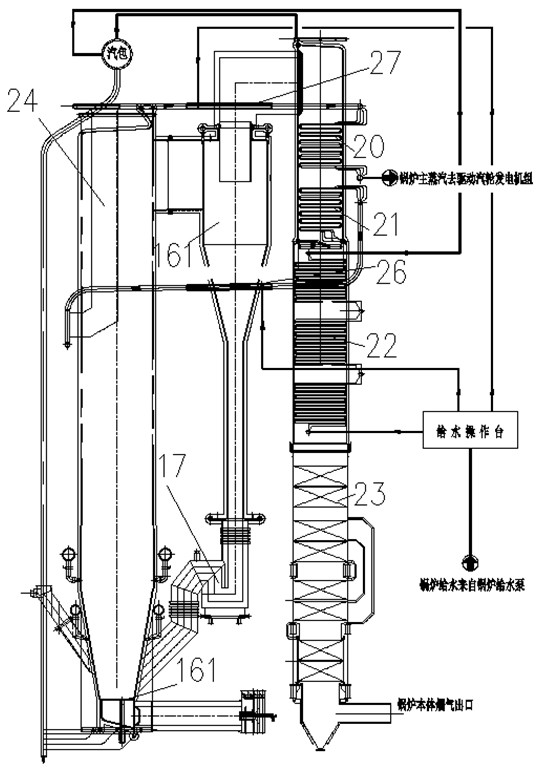

[0072] The circulating fluidized bed boiler includes a circulating fluidized bed boiler body, a primary fan 11, a secondary fan 12, an induced draft fan 13, a feeding fan 14 and a slag cooler 15, and the circulating fluidized bed boiler body includes a furnace 16, a cloth Air plate 161 and air chamber, two cyclone separators 10, "J" valve feeder 17, tail shaft flue 18, steam drum.

[0073] The flue gas outlet at the top of the furnace 16 of the circulating fluidized bed boiler is respectively connected to the upper flue gas inl...

Embodiment 2

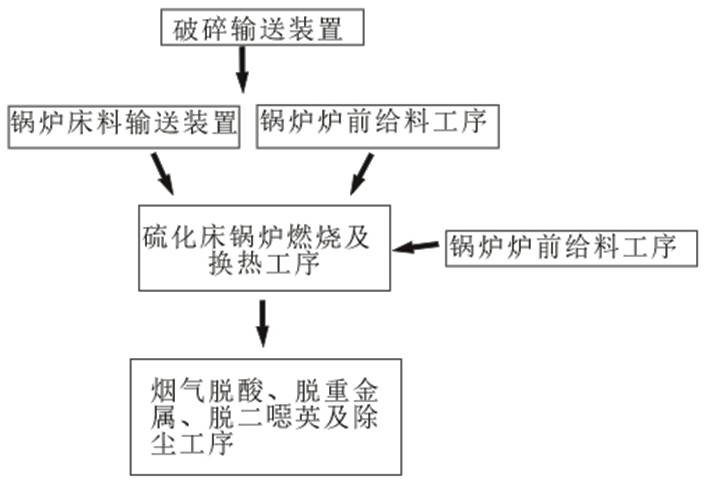

[0090] Based on the above system, the present invention also includes a method for disposing of combustible industrial solid waste,

[0091] See image 3 , including the following steps:

[0092] Step (1): crushing and conveying process

[0093] The combustible industrial solid waste in the industrial solid waste storage warehouse, the combustible industrial solid waste has an ash content of 2% to 9%, and is transported to the primary shredder 31 through the chain conveyor 30 for crushing and primary crushing. The iron remover 32 removes iron to obtain first-grade solid waste particles, and the particle size of the first-grade solid waste particles is ≤150*200mm,

[0094] The first-level solid waste particles are transported to the second-level crusher 33 by the belt conveyor 1 for crushing and the second-level iron remover 34 to remove iron to obtain the second-level solid waste particles, and the particle size of the second-level solid waste particles is ≤80*80mm,

[0095...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com