High-specific-energy fast-charging positive plate and preparation method and application thereof

A technology of positive electrode sheet and content, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve the problems of short battery life, long charging time, limited use, etc., to improve specific capacity, reduce coating difficulty, The effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0055] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0056] In the description of the present invention, it should be noted that the terms "first", "second" and so on are only used for descriptive purposes, and do not indicate or imply relative importance.

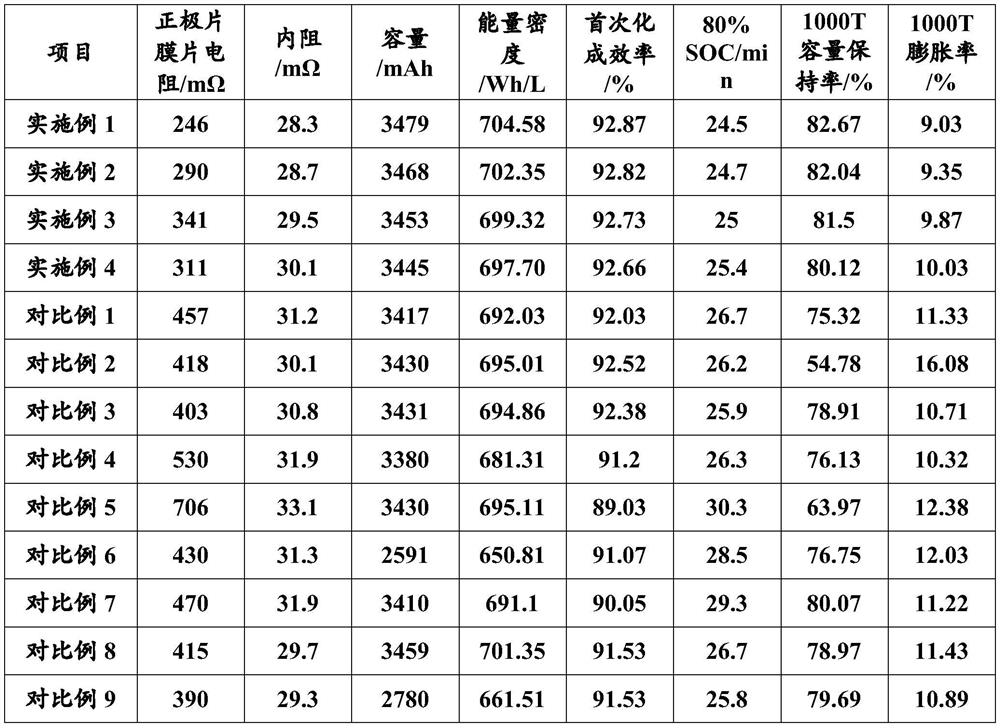

Embodiment 1

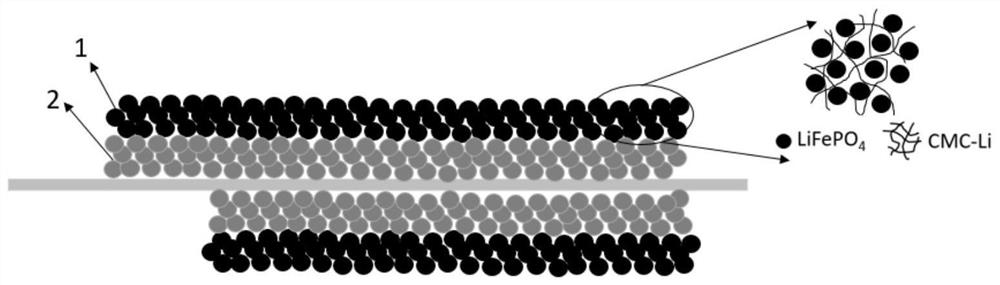

[0058] The first step: prepare the first active material slurry: add the active material (lithium cobaltate), conductive agent (conductive carbon black) and binder (PVDF) into the stirring tank according to the mass ratio of 95.6:3.5:0.9, According to the known batching process, NMP is added and fully stirred, passed through a 200-mesh sieve, and made into the first active material slurry, and the positive electrode slurry has a solid content of 70% to 75%;

[0059] The second step: prepare the second active material slurry: add the active material (lithium iron phosphate), conductive agent (conductive carbon black) and binder (lithium carboxymethyl cellulose) according to the mass ratio of 96.0:2.0:2.0 Put it into the mixing tank, add deionized water according to the known batching process and stir thoroughly, pass through a 200-mesh screen, and make the second active material slurry, the positive electrode slurry has a solid content of 70% to 75%;

[0060] Step 3: Prepare th...

Embodiment 2

[0064] Other preparation steps are with embodiment 1, and difference is only in:

[0065] The first step: Active material (lithium cobaltate), conductive agent (conductive carbon black) and binder (PVDF) are added to the stirring tank according to the mass ratio of 96.0:3.1:0.9;

[0066] The second step: Active material (lithium iron phosphate), conductive agent (conductive carbon black) and binder (lithium carboxymethyl cellulose) are added into the stirring tank according to the mass ratio of 96.5:2.0:1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com