Multifunctional workboat with buoyancy adjusting carrying platform and operation method of multifunctional working ship

A buoyancy adjustment, working boat technology, applied in the direction of hull, hull deck, ship construction, etc., can solve the problems of complex submersible and snorkeling operation process, limited lifting capacity of A frame, expensive rental, etc., and achieve flexible and convenient deployment and recovery methods. The effect of saving working time and energy consumption, and reducing the load on the ballast system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

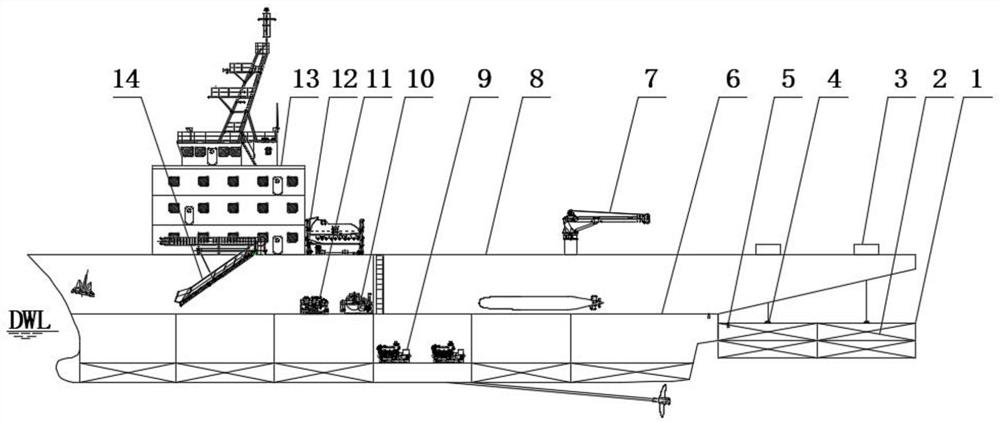

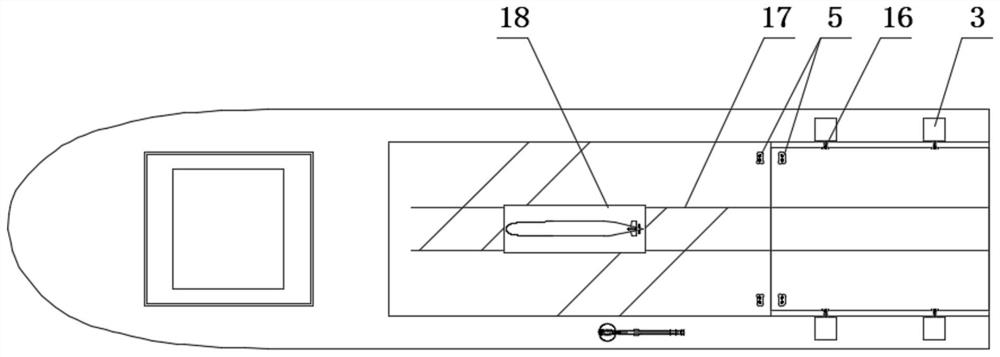

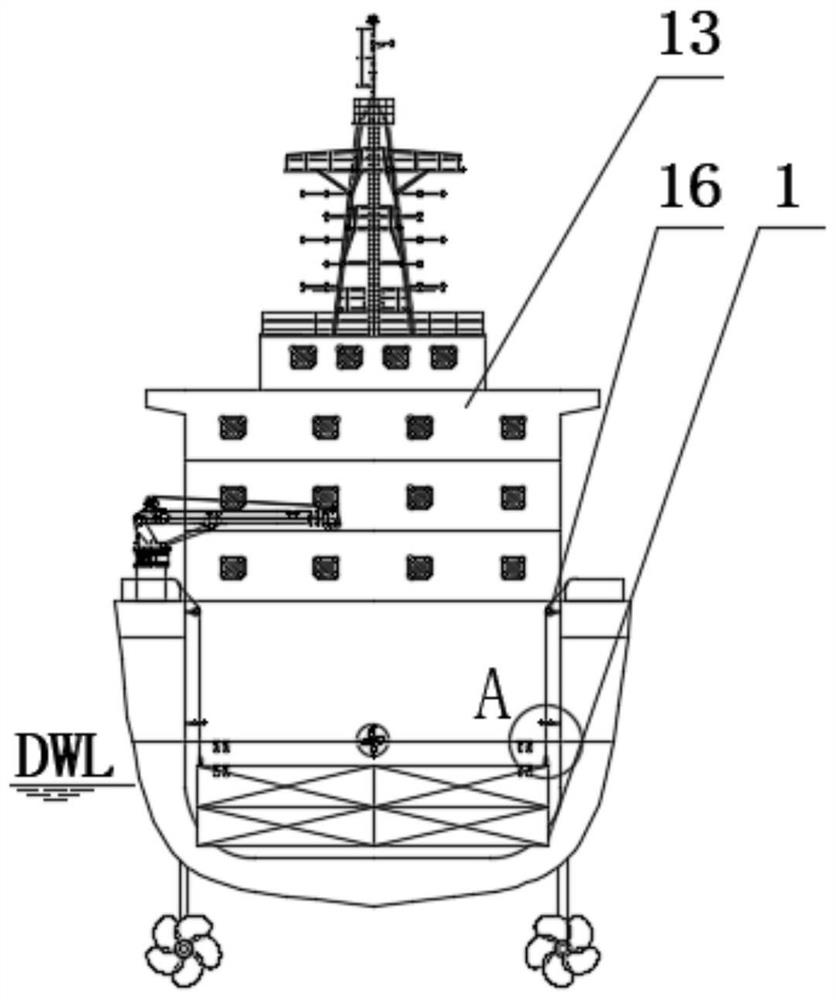

[0037] Such as Figure 1-Figure 7 As shown, the multifunctional workboat with the buoyancy adjustment carrying platform of the present embodiment includes a surface vessel, the surface vessel is provided with a loading deck 6, and the loading deck 6 is distributed with elevating cable bollards 5, towing winches 10, hydraulic pumps Station 11, track 17, transfer flat car 18, marine equipment is placed on the transfer flat car 18, and the transfer flat car 18 walks along the track 17; a main deck 8 is arranged above the loading deck 6, and winches 3, Hanging code, steel cable 4, knuckle crane 7, lifeboat 12, forecastle 13 and gangway 14,

[0038] The buoyancy adjustment carrying platform 1 is installed on the stern of the surface ship, and the buoyancy adjustment carrying platform 1 can realize the floating and diving of the carried object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com