Neutron absorber material, preparation method thereof and control rod

A neutron absorber and absorber technology, which is applied in the control of nuclear reactions, manufacturing reactors, reducing greenhouse gases, etc., can solve the problems of high airtightness and mechanical strength of control rods, inconvenient processing and use, and short service life. , to achieve excellent anti-radiation swelling, long service life, and small radiation creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

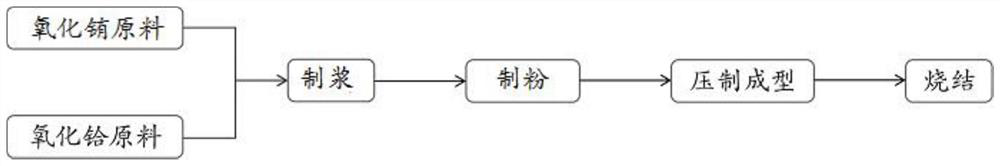

[0039] Correspondingly, the present invention also discloses a method for preparing the above-mentioned neutron absorbing material, including:

[0040] S1 pulping: by weight, prepare a slurry with 30-90 parts of europium oxide raw material and 10-70 parts of hafnium oxide raw material, and grind the solid particles in the slurry to below the submicron level;

[0041] S2 powder making: drying the prepared slurry below the submicron level, then pulverizing and sieving to obtain powder particles with the required particle size;

[0042] S3 Compression molding: Press the sieved powder particles into plain embryos;

[0043] S4 sintering: sintering the plain embryo at high temperature to obtain the neutron absorber material.

[0044] And, the present invention also discloses a control rod, which includes a cladding and an absorber, the absorber is arranged in the inner space of the cladding, and the absorber is processed by using the neutron absorber material mentioned above.

Embodiment 1

[0046] This embodiment discloses a method for preparing a neutron absorber material, which includes the following steps:

[0047] S1 pulping: by weight, take 30-90 parts of europium oxide raw material and 10-70 parts of hafnium oxide raw material to prepare slurry, and grind the solid particles in the slurry to below the submicron level.

[0048] Among them, the purity of the europium oxide raw material is 95-100%, and the purity of the hafnium oxide raw material is 80-100%.

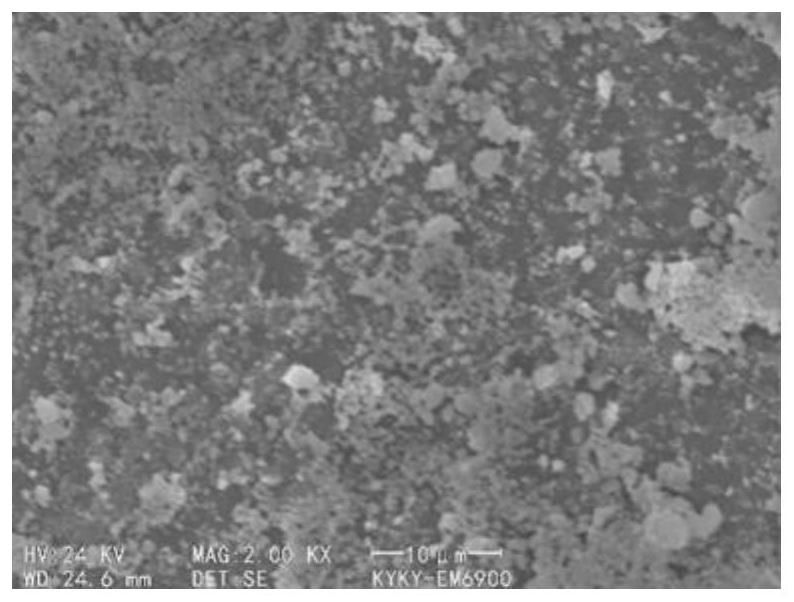

[0049] Specifically, the europium oxide raw material and hafnium oxide raw material are added to the solvent according to the above ratio, a dispersant is added, and ball milling is performed at a speed of 150-200r / min for 2-24 hours to obtain a slurry with a solid particle size below the submicron level (that is, the particle size of the solid particles is less than 100nm), and the distribution of europium oxide and hafnium oxide in the slurry below the submicron level is more uniform, and the performan...

Embodiment 2

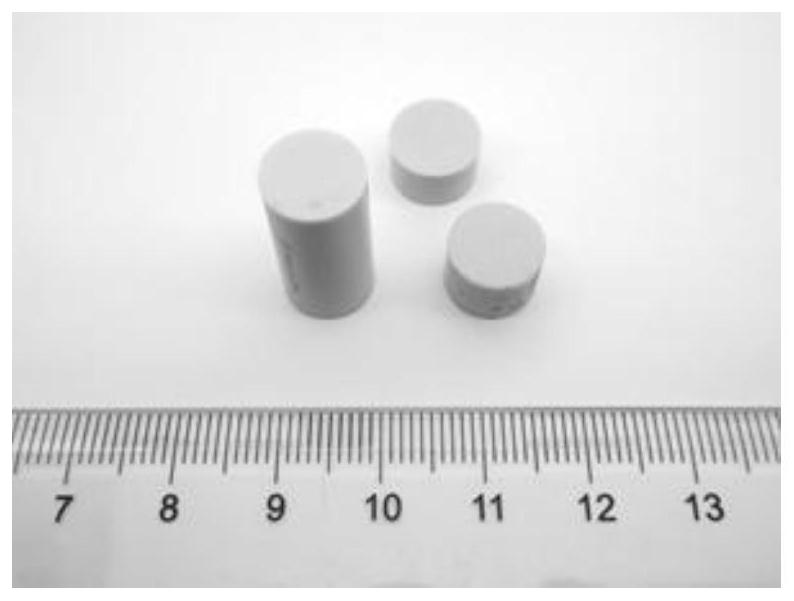

[0065] Such as Figure 5 As shown, this embodiment discloses a control rod, including a cladding 3, an end plug, and an absorber 4, wherein the absorber 4 is processed by using the neutron absorbing material prepared by the method described in Example 1.

[0066] Specifically, the absorber 4 is arranged in the inner space of the casing 3, and the absorber 4 is preferably arranged in multiple sections, so as to reduce damage to the control rods caused by radiation swelling and the like. The end plugs include a first end plug 1 and a second end plug 5 , which are respectively arranged at two ends of the casing 3 , and can be sealed and connected by means of welding or the like, and the absorber 4 is clamped inside the casing 3 . The cladding 3 can be made of stainless steel or nickel-based alloy. In some alternative embodiments, one of the end plugs (such as Figure 5 One end of the second end plug 5) in the middle is set to a sharp shape, and on the other (such as Figure 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com