Temperature-controlled cooling mother liquor as well as preparation method and application thereof

A technology of temperature-controlled cooling and mother liquor, which is applied to chemical instruments and methods, heat exchange materials, etc., can solve problems such as temperature instability, increased wear, and waterway blockage, so as to improve work efficiency, heat up quickly, and prevent scale. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

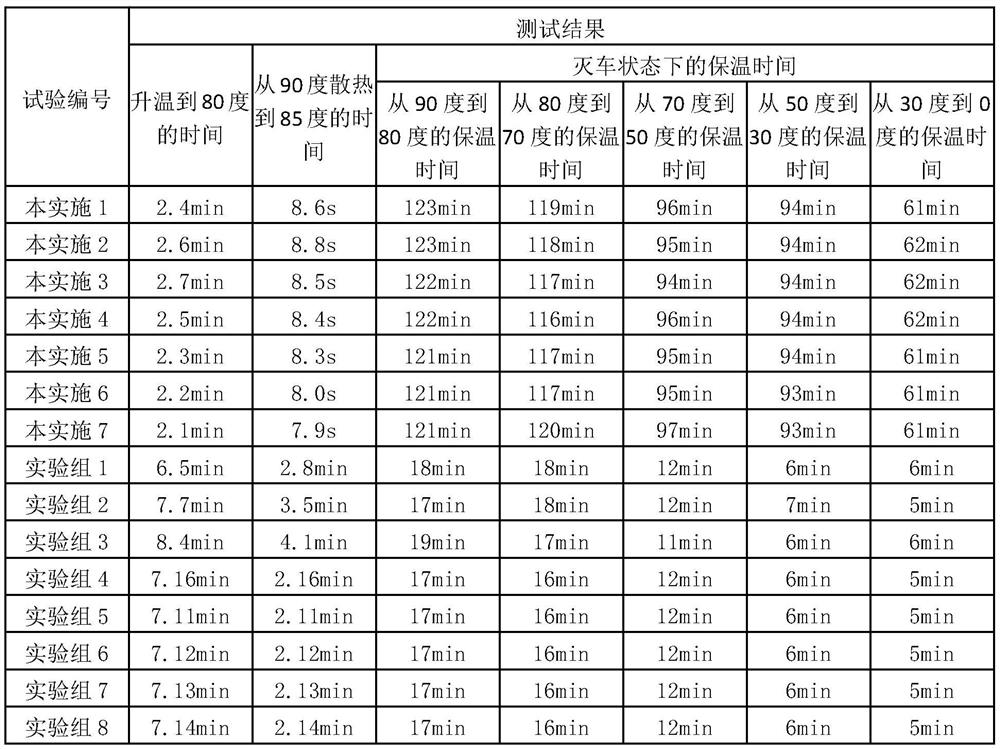

Examples

Example Embodiment

[0042] 2. Preparation method of temperature-controlled cooling mother liquor

[0043] The preparation method of the temperature-controlled cooling mother liquor includes the following steps according to the sequence:

[0044] The first step is to mix sucrose, sodium benzoate, calcium chloride, phenylpropanazole, sodium molybdate and triethanolamine, add deionized purified water, and heat to melt to form the first part of the mixed solution;

[0045] The second step is to mix N-methylpyrrolidone and allyl glycidyl ether, graphene oxide dispersion and nitrate and gold chloride, then mix all the above two mixtures, and then add anthomethyl fiber Vegetarian, forming the second part of the mixture;

[0046] In the third step, the mixture in the second step is heated to 80-100°C, and then placed to return to the natural temperature, which is 18-24°C, and the heating and temperature return are repeated 3 times within 48 hours;

[0047] In the fourth step, the mixed liquid obtained in the firs...

Example Embodiment

[0056] Example 1

[0057] Mother liquor-propylene glycol antifreeze, including the first part of the mixed liquid and the second part of the mixture and the propylene glycol antifreeze, the added amount of the propylene glycol antifreeze is both the first part of the mixture and the second part of the mixture 2% of the total amount, the propylene glycol antifreeze is a mixture of propylene glycol and deionized purified water, and the pH value of the temperature-controlled, energy-saving, environmentally friendly antifreeze coolant is between 7-8;

[0058] The first part of the mixed solution is prepared by mixing the following parts by weight: 0.3 parts of sucrose, 0.08 parts of sodium benzoate, 0.1 parts of calcium chloride, 0.08 parts of phenylpromazole, 0.03 parts of sodium molybdate, 0.03 parts Parts of triethanolamine and 5.5 parts of deionized purified water;

[0059] The second part of the mixed solution is prepared by mixing the following parts by weight: 0.01 parts of N-met...

Example Embodiment

[0067] Example 2

[0068] Mother liquor-propylene glycol antifreeze, including the first part of the mixed liquid and the second part of the mixture and the propylene glycol antifreeze, the added amount of the propylene glycol antifreeze is both the first part of the mixture and the second part of the mixture 3% of the total amount, the propylene glycol antifreeze is a mixture of propylene glycol and deionized purified water, and the pH value of the temperature-controlled, energy-saving and environmentally friendly antifreeze coolant is between 7-8;

[0069] The first part of the mixed solution is prepared by mixing the following parts by weight: 0.4 parts sucrose, 0.1 parts sodium benzoate, 0.2 parts calcium chloride, 0.1 parts phenylprotriazole, 0.04 parts sodium molybdate, 0.04 parts Parts of triethanolamine and 7.5 parts of deionized purified water.

[0070] The second part of the mixed solution is prepared by mixing the following parts by weight: 0.02 parts of N-methylpyrrolido...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com