High-temperature corrosion and scale inhibitor for hot-water heat-supply network of winter heating and preparation method of high-temperature corrosion and scale inhibitor

A corrosion and scale inhibitor, hot water pipe technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. The problems of poor solubility of azoles and high cost of raw materials can achieve the effect of improving tolerance, good effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

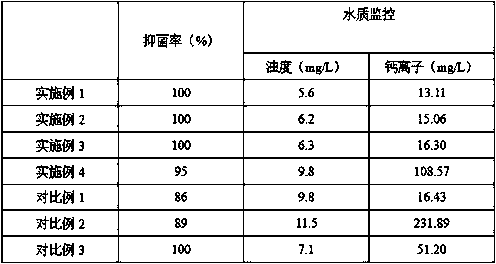

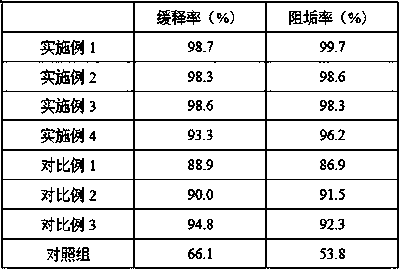

Embodiment 1

[0022] A high-temperature corrosion and scale inhibitor for heating and hot water pipe network in winter, the formula is: 2 parts of ethylenediaminetetraacetic acid, 0.6 part of polyaspartic acid, 1.2 parts of diethyl sulfate, 0.6 part of carboxymethyl chitosan , 0.2 parts of polyvinylpyrrolidone, 0.2 parts of starch sodium octenylsuccinate, and 0.1 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride.

[0023] The preparation method is as follows:

[0024] (1) Add 0.6 parts of carboxymethyl chitosan to 3 parts of distilled water, after dissolving, add 3-chloro-2-hydroxypropyltrimethylammonium chloride, stir evenly, heat up to 80-85°C and keep warm Stir for 40-50min, then cool to room temperature to obtain a premix;

[0025] (2) Add water to the mixture of ethylenediaminetetraacetic acid, polyaspartic acid, diethyl sulfate, polyvinylpyrrolidone, and sodium starch octenyl succinate in a mass ratio of 1:1, mix well, and then Add the premix and mix well.

Embodiment 2

[0027] A high-temperature corrosion and scale inhibitor for heating and hot water pipe network in winter, the formula is: 2.5 parts of ethylenediaminetetraacetic acid, 0.5 part of polyaspartic acid, 1.0 part of diethyl sulfate, 0.8 part of carboxymethyl chitosan , 0.3 parts of polyvinylpyrrolidone, 0.1 parts of starch sodium octenyl succinate, and 0.1 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride.

[0028] The preparation method is the same as in Example 1.

Embodiment 3

[0030] A high-temperature corrosion and scale inhibitor for heating and hot water pipe networks in winter, the formula is: 3 parts of ethylenediaminetetraacetic acid, 0.8 part of polyaspartic acid, 0.8 part of diethyl sulfate, and 0.5 part of carboxymethyl chitosan , 0.4 parts of polyvinylpyrrolidone, 0.3 parts of starch sodium octenylsuccinate, and 0.1 parts of 3-chloro-2-hydroxypropyltrimethylammonium chloride.

[0031] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com