Method for preparing pellets from K2O, Na2O and F containing iron ore concentrate and high magnesium composite binder

A binder preparation and binder technology, applied in the field of agglomeration of ironmaking raw materials, can solve the problems of lower grade of finished pellets, poor cohesiveness, and restrictions on the production of magnesia pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

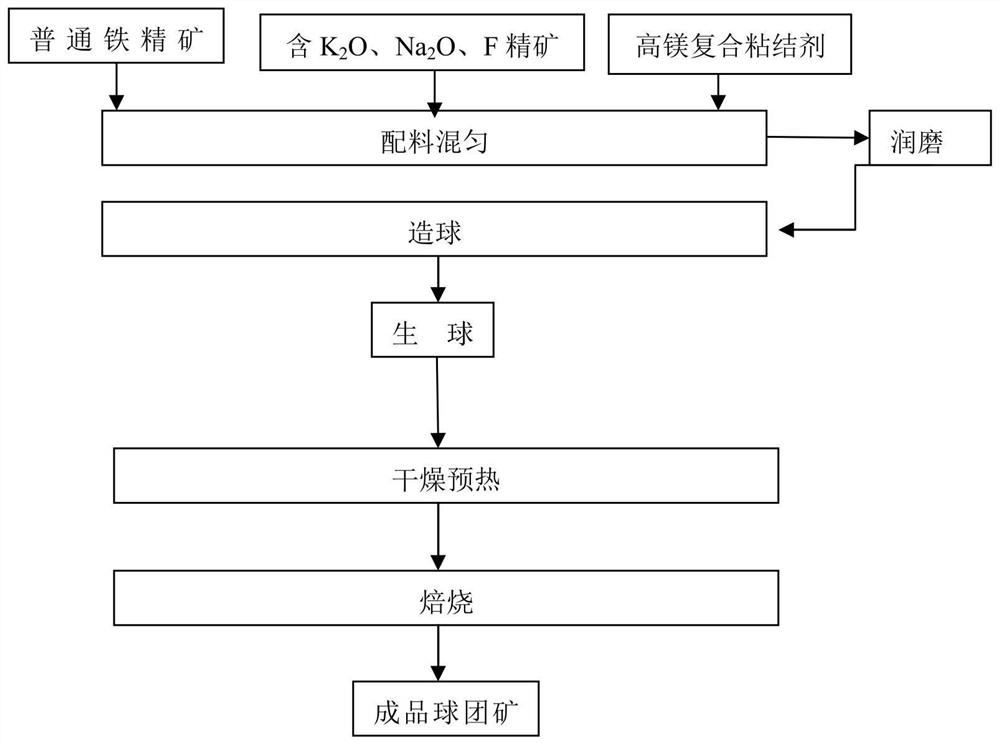

Method used

Image

Examples

example

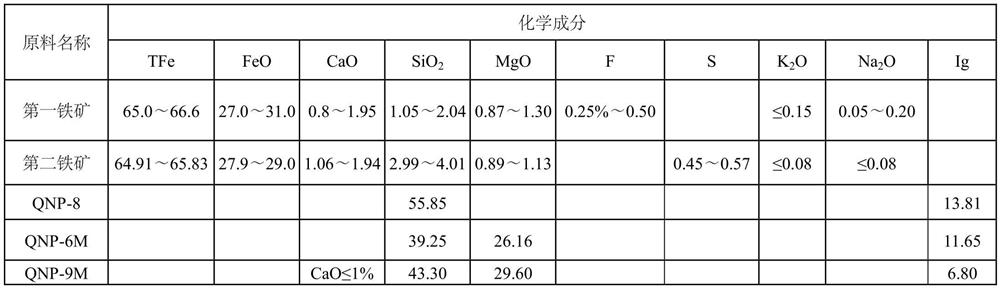

[0029] Each example application contains K 2 O, Na 2 See Tables 1-4 for the raw material composition, ore blending scheme, pellet chemical composition and related properties of O and F concentrates mixed with high-magnesium binder to prepare pellets.

[0030] Table 1: Chemical Composition of Raw Materials, %

[0031]

[0032] Note: The QNP-8 binder (non-high-magnesium composite binder) in Table 1 was purchased from Baotou Gangxing Industrial (Group) Xinxing Metallurgical Raw Materials Co., Ltd.

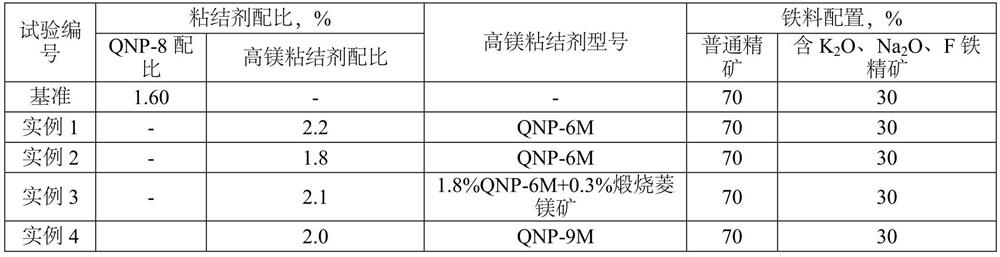

[0033] Table 2: Test plan for adding high magnesium binder

[0034]

[0035] Table 3: The effect of adding different types of high-magnesium binders on the performance of green balls

[0036] Test No. Moisture, % Drop strength, times / P Green pellet compressive strength, N / P benchmark 6.90 5.85 15.96 Example 1 6.85 8.55 15.71 Example 2 6.90 5.70 15.20 Example 3 7.05 6.10 15.27 Example 4 7.10 6.05 15.86

[0037] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com