Hydraulic tunnel pipeline installation trolley, installation system and installation method

A technology for pipeline installation and trolley installation, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as difficult rotation, large pipeline volume, and failure of joints between pipe joints, so as to save construction time, simplify construction process, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

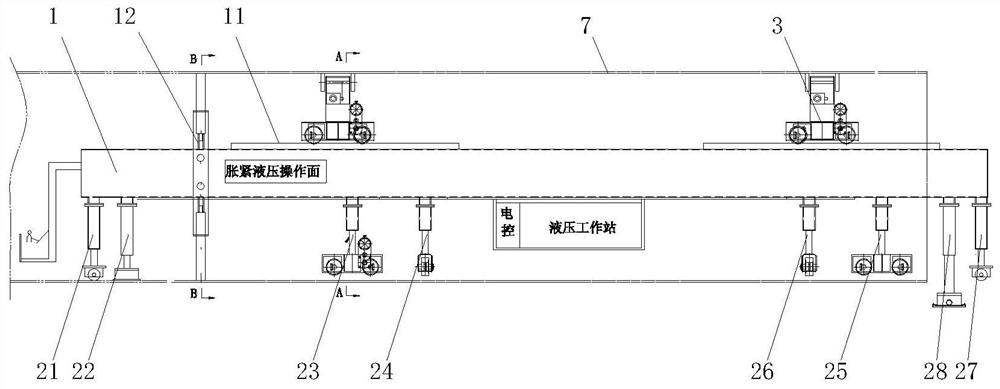

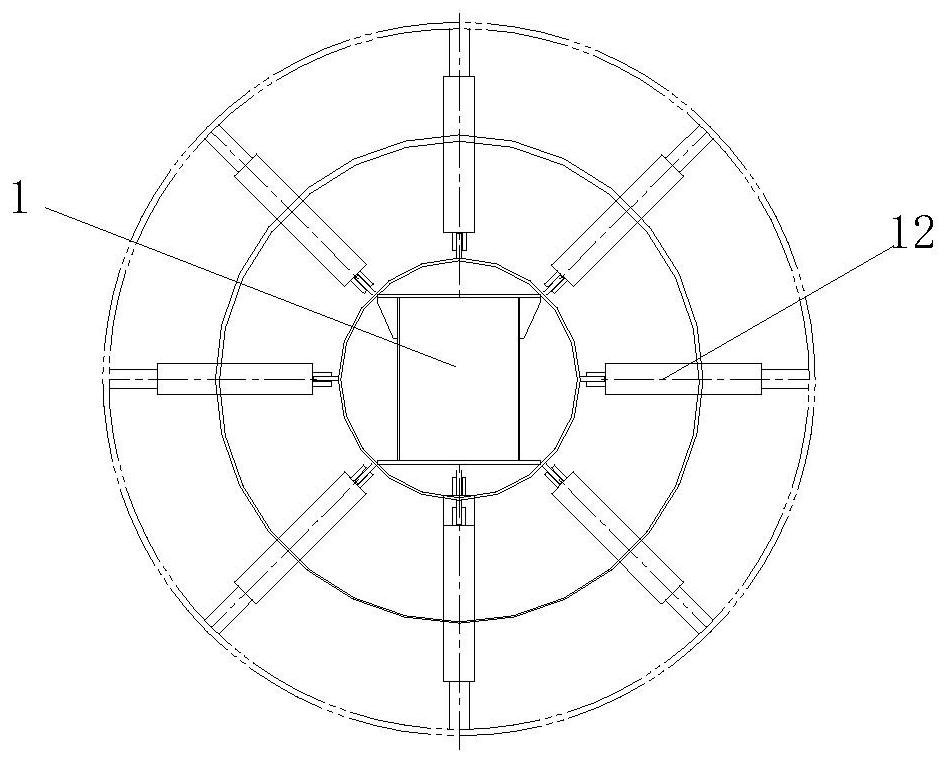

[0043] combined with figure 1 As shown, a hydraulic tunnel pipeline installation trolley related to the present invention includes a main beam 1, a traveling mechanism and a trolley 3, and a track 11 is provided above the main beam 1; the traveling mechanism includes sequentially from left to right The first walking support 21, the first supporting 22, the second walking supporting 23, the second supporting 24, the third walking supporting 25, the third supporting 26, the fourth walking supporting 27 and the fourth supporting 28 arranged under the main beam, The first walking support 21, the first supporting 22, the second walking supporting 23, the second supporting 24, the third walking supporting 25, the third supporting 26, the fourth walking supporting 27 and the fourth supporting 28 are equipped with a jacking mechanism.

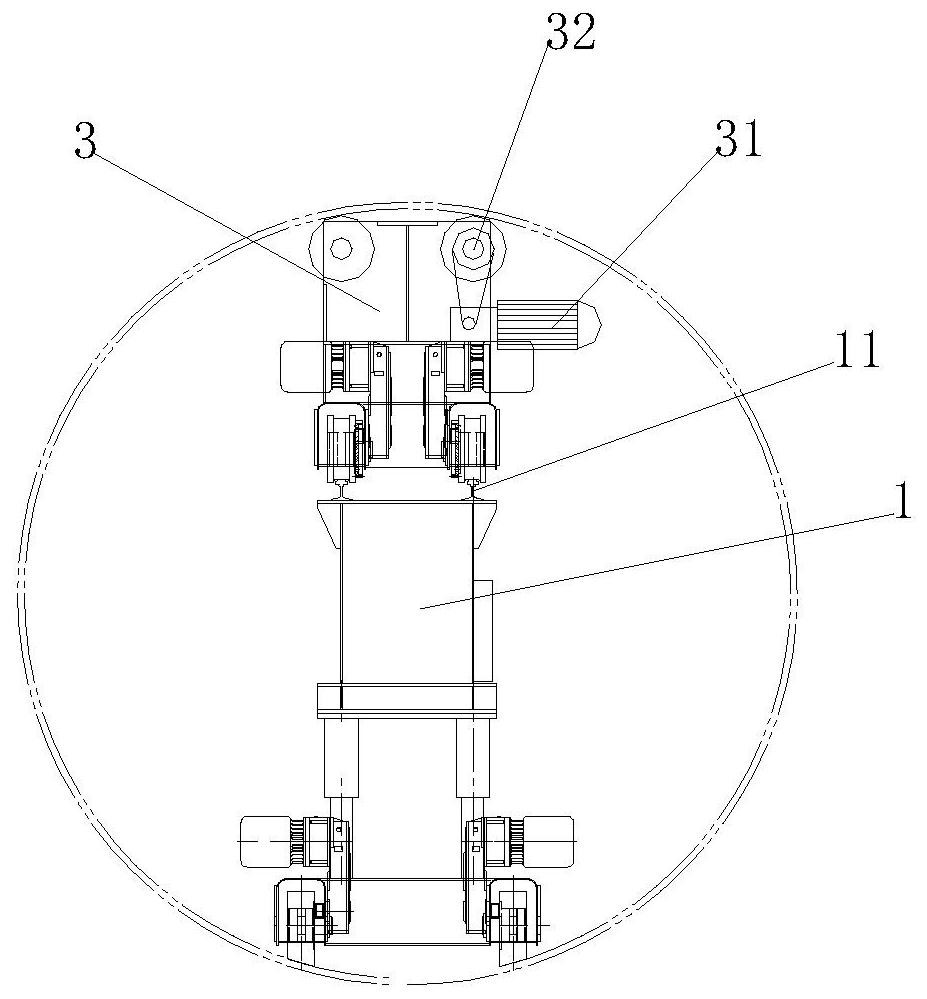

[0044] combined with figure 1 and 2 As shown, the tube-carrying trolley 3 is installed on the track 11, and the tube-carrying trolley 3 is provided ...

Embodiment 2

[0047] combined with Figure 4 As shown, a hydraulic tunnel pipeline installation system related to this embodiment includes an installation trolley, a transport trolley and a traction mechanism.

[0048] The installation trolley includes a main girder 1, a traveling mechanism and a load-carrying trolley 3, and a track 11 is arranged above the main girder 1; One support 22, the second walking support 23, the second support 24, the third walking support 25, the third supporting 26, the fourth walking supporting 27 and the fourth supporting 28, the first walking supporting 21, the first supporting 22, the second supporting The walking support 23 , the second support 24 , the third walking support 25 , the third support 26 , the fourth walking support 27 and the fourth support 28 are all equipped with jacking mechanisms.

[0049] The tube trolley 3 is installed on the track 11, and the tube trolley 3 is provided with at least two groups, driven by a walking drive motor or driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com