Vaporization device of liquefied gas storage tank

A technology of liquefied gas and vaporization device, which can be used in gas processing/storage purposes, gas/liquid distribution and storage, fixed-capacity gas storage tanks, etc. The effect of footprint and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

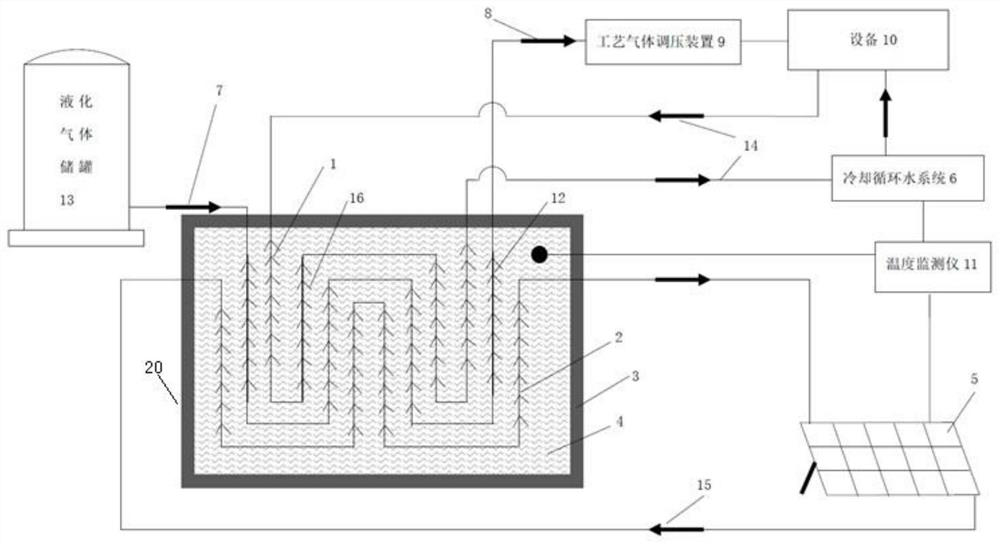

[0021] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] like figure 1 As shown, a vaporization device for a liquefied gas storage tank includes a vaporizer chamber 20, the inner wall of the vaporizer chamber 20 is provided with a heat insulating layer 3, a phase change material 4 is arranged in the vaporizer chamber 20, and a vaporizer chamber 20 is also provided with There are multiple sets of heat exchange devices, at least two sets of heat exchange devices, including the first heat exchange device 12 and the second heat exchange device 2, the input end of the first heat exchange device 12 is connected to the liquefied gas storage through the low-temperature liquefied gas input pipeline 7 The tank 13, the output end of the first heat exchange device 12 is connected to the gas consumption equipment 10 through the process gas output pipeline 8, the input end and output end of the second h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com